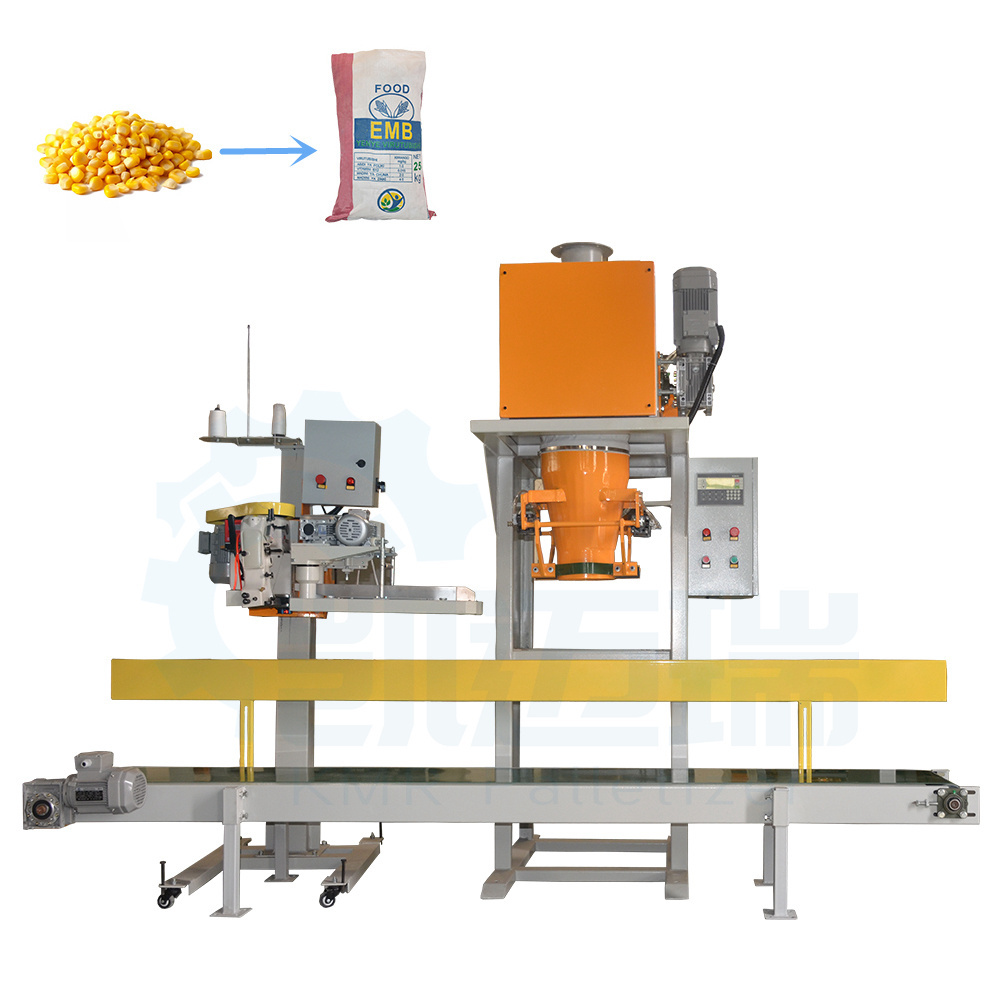

The working principle of the granule packaging machine is usually to transport the granular material to the filling part of the packaging machine through the conveying system, where it is filled according to the set specifications and quantity, and then the packaging bag is sealed.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

550

-

Voltage:

-

380v, or customized

-

Place of Origin:

-

Henan

-

Brand Name:

-

KMR

-

Dimension(L*W*H):

-

3240*1300*2070mm

-

Sealing type:

-

sewing or heat sealing

-

Packaging speed:

-

200-300bags/h

-

Product name:

-

Granular Packing Machine

-

Packing Material:

-

Pellet, granular

-

Weighing Range:

-

20-50kg

-

Weighing Height:

-

2754mm

-

Weighing Accuracy:

-

±0.2%

-

Packing Machine Function:

-

Muti-function

-

Control system:

-

PLC+Servo+Touch Screen

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, Laminating, Sealing, Gluing

-

Packaging Type:

-

Bags

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

550

-

Voltage:

-

380v, or customized

-

Place of Origin:

-

Henan

-

Brand Name:

-

KMR

-

Dimension(L*W*H):

-

3240*1300*2070mm

-

Sealing type:

-

sewing or heat sealing

-

Packaging speed:

-

200-300bags/h

-

Product name:

-

Granular Packing Machine

-

Packing Material:

-

Pellet, granular

-

Weighing Range:

-

20-50kg

-

Weighing Height:

-

2754mm

-

Weighing Accuracy:

-

±0.2%

-

Packing Machine Function:

-

Muti-function

-

Control system:

-

PLC+Servo+Touch Screen

Products Description

Semi-automatic Packing Machine

The granule packing machine

is suitable for rationing package of the loose nonstick grains or the powdery material in the feed, food, grain, chemical industry. For example pellet wholesome material, mixture, corn, rice, grain, wheat and grainy seed, feed, food, and chemical material etc.

Specification

|

Gross Weight

|

550kg

|

|

Packing Capacity

|

200-300bags/h

|

|

Weighing Range

|

5-50kg or customized

|

|

Quantify Precision

|

±0.2%

|

|

Power

|

1kw

|

|

Power Supply

|

AC 220V/380V, 50HZ, 1P/3P, Customized

|

|

Air Source

|

0.4~0.6MPa 0.36m³/min

|

|

Application Materials

|

Applicable for packing granular or particle materials such as chemistry, fertilizer, grain, rice, sand, wood pellets, animal feed,

urea, phosphate, PP, PE granules, construction materials, etc.

|

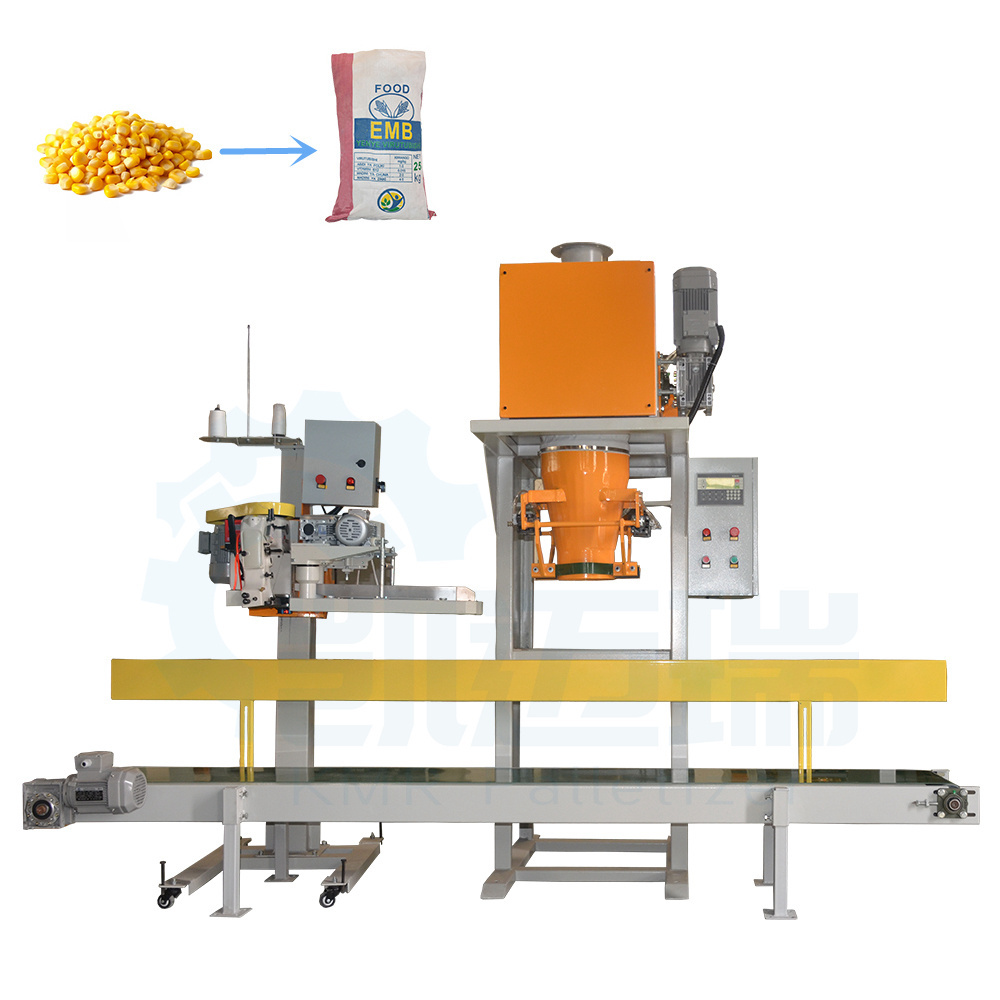

Unloading Hopper

1.

It

is made of wear-resistant and corrosion-resistant materials to extend its service life;

2.

The unloading speed is adjustable;

Easy to clean;

3.

Good sealing performance to prevent particle leakage and external impurities from entering;

4.

Equipped with safety protection devices, emergency stop devices, etc.;

Sewing Machine

1.

Different sealing forms can be selected: flat seam, chain seam, etc.;

High sealing strength

2.

Photoelectric induction automatically pneumatic thread trimming after sewing bags, saving labor

3.

Thread tension and sewing density are adjustable.

4.

Suitable for a variety of packaging materials: plastic bags, paper bags, etc.

Operation Panel

1.

Graphical interface, easy to operate;

2.

Adjustable parameters: packaging speed, quantity, sealing temperature, etc.

3.

Design alarm and prompt functions, such as insufficient material, failure, etc.

4.

Data recording and reporting functions facilitate quality control and production management.

5. Multiple languages available

: English, Spanish, Russian, French, etc.;

Belt Conveyor

1.

Large carrying capacity;

2.

Conveying speed: 5-20m/min

3.

Made of rubber material, it is wear-resistant and corrosion-resistant; it can operate stably for a long time;

4.

Height, angle, speed, etc. can be adjusted according to production needs.

5.

Safety protection devices: protective cover, safety switch light;

Application

Advantages of Granule Packaging Machines :

1. High degree of automation:

Granule packaging machines are usually highly automated and can complete multiple steps such as measuring, filling, sealing, and printing date and batch numbers of granular materials, which greatly improves production efficiency and reduces labor costs.

2. Precise packaging capabilities:

These machines can accurately package granular materials according to preset specifications and quantities, ensuring a consistent amount of material in each packaging bag and ensuring product quality and hygiene.

3. Flexible adaptability:

Granule packaging machines usually have flexible adjustment and customization functions, which can be adjusted according to different packaging requirements, adapt to various packaging bags of different specifications and shapes, and meet the needs of different customers.

4. Reliable sealing performance:

Granule packaging machines are usually equipped with efficient sealing systems, which can ensure the sealing and sealing performance of packaging bags and effectively prevent products from moisture, oxidation or contamination.

5. Advanced control technology:

Modern granule packaging machines usually use advanced control technology, such as PLC control systems, touch screen operation interfaces, etc., which are easy to operate, stable and reliable, and easy to maintain and manage.

Packing & Shipping

Hot Searches