- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*150*200 mm, 240*115*90 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Huatong

-

Voltage:

-

220/380/440V

-

Dimension(L*W*H):

-

3000*1900*2930mm

-

Warranty:

-

2 Years, 2 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Power:

-

50Kw

-

Water consumption:

-

5-12T

-

Workers:

-

14

-

Whole weight:

-

10T

-

Certification:

-

ISO9001, CE

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

50000 pieces/day

-

Brick size:

-

400*100*200 mm, 400*150*200 mm, 240*115*90 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Huatong

-

Voltage:

-

220/380/440V

-

Dimension(L*W*H):

-

3000*1900*2930mm

-

Warranty:

-

2 Years, 2 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Power:

-

50Kw

-

Water consumption:

-

5-12T

-

Workers:

-

14

-

Whole weight:

-

10T

-

Certification:

-

ISO9001, CE

QT5-15 Automatic Brick Machine Interlocking Brick Making Machine Price

QT5-15 Automatic block machine production line, working automatically through PLC control system

QT5- 1 5 ( 5 stands for 5 pics in every mould of hollow blocks (390 x190x190mm) , and 15 seconds for every cycling time ).

Main Features

Ø The machine is made of super-strong steel with special welding techniques, which is extremely strong and

shock-proof.

Ø Special treatment of Mould: M ould wear resisting performance is greatly enhanced through quenching tempering, carburizing, boronizing as well as various kinds of heat t reatment process . T he service life is greatly improved , longer than the national standard .

Ø The integration of the vibration table and the synchronous mode of vibration achieve d the best effect of compacting machine. The machine adopts four -pole orientation mode, extended wear resistant guide sleeve ensure the accuracy movement of mould and head . Materials feeder a dopts oriented operation mode , obviously reduce d mould load , doing perfect spreading work.

Ø V ibration system: The host machine is frequency control learning from frequency conversion technology of Germany . T he vibrator is assembled with oil immersed type , improv ed the brick density , sav ing electricity, molding fast .

|

Main Technical Specifications |

|

|

Standard |

JC/T920-2003 |

|

Vibration Frenquency |

3500 cycles/minute |

|

Vibration Pressure |

70KN |

|

Production/mould |

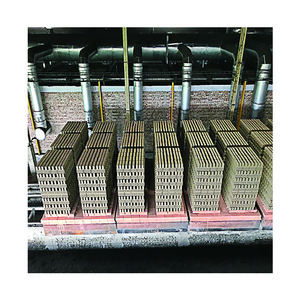

Hollow block (390 × 190 × 190mm) 5 Pics/mould |

|

Hollow block ( 245 ×115×90 mm) 16 Pics/mould |

|

|

Solid Brick (245 ×115×53 mm) 32 Pics/mould |

|

|

Paver brick ( 200 ×100×60 mm ) 18 pieces/mould |

|

|

Cycle Time |

1 5 -25seconds |

|

Production/day(8hours) |

Hollow block(390 ×190×190 mm ) 5800 -6300 Pics |

|

Hollow block (245 ×115×90 mm) 18500-20000Pics |

|

|

Solid brick (240 ×115×53 mm) 45000-57000Pics |

|

|

Paver brick (200 ×100×60 mm) 21000-23000Pics |

|

|

Motor Power |

29.7KW |

|

Water Consumption |

5-9T |

|

Number of workers |

6-10worker |

|

Space of Ground |

3600m2 |

|

Gross Weight |

10T |

|

Machine Dimension |

3000x1900x2930mm |

|

Pallet size |

1100 ×700×30mm |

|

Main materials |

Cement, crushed stone dust, gravel,sand, coal fly ash, iron/aluminium dust, crushed cinder and some industrial wastes |

|

Products of machine |

Hollow blocks, Solid bricks,P avers,K urbstones, Slope blocks, slabs, interlock bricks and so on. |

Fully Automatic Advantages:

1. Synchronous system: Main machine mould adopt compel synchronization by double-

shaft tooth. Gear and double shaft balance system can make male and female mould move stably without

any jamming phenomenon. It makes the production process more smoothly.

2. Feeding System: There is almost no power loss of gear transmission between different shafts. The concrete feeding machine is 360 degree rotating forced feeding system. It is quick speed and well distributed,

suitable for all kinds of raw materials and mould.

3. Hydraulic System: The hydraulic system adopts high and low pressure dual pump and proportional valve.

The valve can adjust flow rate and buffer cylinder. Therefore, it can protect cylinder, extend life, make

operation steadily and quickly.

4. PLC System: Our block making machine adopt Germany converter technique and intelligent control. It

makes electric motors fitting for wide voltage range. It reduced the starting current of electric motors,

saving 30% electricity than old electric motors. Moreover, the electric motors working with brake resistance

as one set, which can make the vibration system start and stop instantly. It reduce cycle time and increase

production speed.

5. Mould: It adopts special steel materials processed in two times heat treatment with carburizing technology.

Working life of the mould is greatly improved.

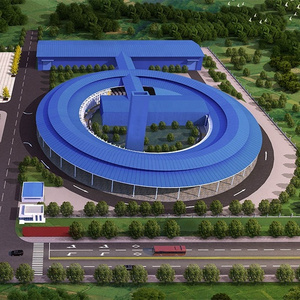

Huatong Hydraulic Machinery Co., Ltd is belongs to Alin group, which is founded in 1986,

one of the leading supplier of Concrete Block Machine, AAC Block production plant, Concrete Batching plant, cement concrete mixing station in China .

We are t he top brand of block making machine in china, AAA Enterprise of Quality and Service , and certificated by ISO9001. All the main parts of the production lines are made by our own factories, that's why we can give you most competitive price. We have established branch offices in Algeria, Pakistan, Ghata, Indonesia, Vietnam. Our machines have been exporting to more than 40 countries and reigions.

Sincerely welcome you to visit our factories!

Our full life service!

We have big technical t eam of more than 50 staffs, offer f ull life service to guarantee our customers using our easy operating machine with fruitful profit!

1. We will give you scientific advice and help you to select proper machine before placing order .

2. After shipment made, We will send our engineer to your area helping you to make factory design.

Before machine reaching your area, more engineers will go to your factory preparing installation

and debugging .

3. Our eng i neers will fi ni sh all work until the machine start nice working. We will train your own

engineers of the machine repairation and m ain tenance .

4. At any time, if the machine could not work well, our engineer will help you to solve the problems. If necessary, we will send our engineer to your factory to repair the machine or replace the parts.

5. One time buying, full life service and co-operation.

Maybe you don't know how to choose a suitable type machine, please follow with me.

1.Do you want a semi-automatic machine or automatic machine?

2.Do you already have land or plan to buy new land ?

3.How much do you want to invest in this project?

4.what kind of block do you want to produce?what is the size?How many pieces do you want to make in 8 hours?

Please feel free to contact me at any time.