- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Low-density polyethylene (LDPE) granules

-

Grade:

-

Virgin Film Injection Grade

-

Appearance:

-

LDPE Clear Pellets

-

Application:

-

Film Injection Blow Molded,Wire And Cable Grade

-

Keywords:

-

Ldpe Film Grade Granules

-

DENSITY:

-

0.918~0.935g/cm3

-

Package:

-

25kg/bag

-

Color:

-

translucent

-

MOQ:

-

1 Ton

-

Features:

-

high fluidity and good processability

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

hebeichangsheng

-

Model Number:

-

LDPE granules

-

Product name:

-

Low-density polyethylene (LDPE) granules

-

Grade:

-

Virgin Film Injection Grade

-

Appearance:

-

LDPE Clear Pellets

-

Application:

-

Film Injection Blow Molded,Wire And Cable Grade

-

Keywords:

-

Ldpe Film Grade Granules

-

DENSITY:

-

0.918~0.935g/cm3

-

Package:

-

25kg/bag

-

Color:

-

translucent

-

MOQ:

-

1 Ton

-

Features:

-

high fluidity and good processability

Product Description

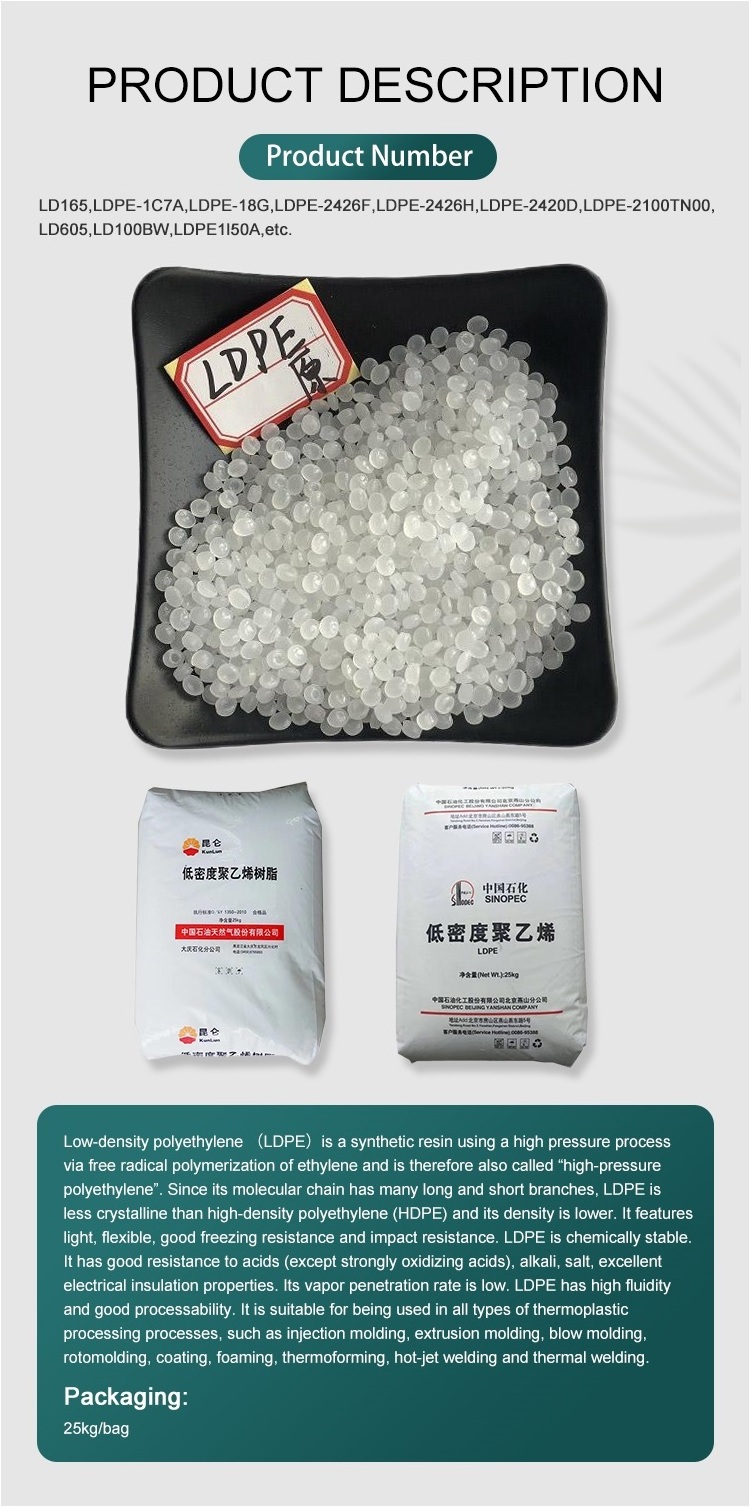

LDPE Description:

Low-density polyethylene(LDPE)is a synthetic resin using a high pressure process via free radical polymerization of ethylene and is therefore also called “high-pressure polyethylene”. Since its molecular chain has many long and short branches, LDPE is less crystalline than high-density polyethylene (HDPE) and its density is lower. It features light, flexible, good freezing resistance and impact resistance. LDPE is chemically stable. It has good resistance to acids (except strongly oxidizing acids), alkali, salt, excellent electrical insulation properties. Its vapor penetration rate is low.LDPE has high fluidity and good processability. It is suitable for being used in all types of thermoplastic processing processes,such as injection molding, extrusion molding, blow molding, rotomolding, coating, foaming, thermoforming, hot-jet welding and thermal welding.

Packaging:

25kg/bag

Specification

|

Grades

|

LD165

|

LDPE-2100TN00

|

LDPE-18G

|

LDPE-2426F

|

LDPE-2426H

|

|

Density,g/cm³

|

0.9214

|

0.9192

|

0.918

|

0.923

|

0.923

|

|

MFR,g/10min

|

0.30

|

0.308

|

7

|

0.8

|

1.9

|

|

Stretching broken column nominal strain,%

|

548

|

529

|

-

|

MD200

TD600 |

600

|

|

Tensile strength at broken,

Mpa

|

15.8

|

14.5

|

-

|

MD26

TD20 |

15

|

|

Haze,%

|

10

|

-

|

-

|

-

|

8

|

|

Fisheye(0.3mm-0.2mm),

qty/1200cm²

|

25

|

-

|

-

|

-

|

-

|

|

Swell ratio,/

|

-

|

-

|

1.55

|

-

|

-

|

|

Turbidity,%

|

-

|

-

|

-

|

<8

|

-

|

|

Gloss,%

|

-

|

-

|

-

|

>40

|

-

|

|

Film Thickness,μm

|

-

|

-

|

-

|

50

|

-

|

|

Modulus of Elasticity,Mpa

|

-

|

-

|

-

|

260

|

-

|

|

Dart Impact Strength,g

|

-

|

-

|

-

|

130

|

-

|

|

Vicat Softening Point,℃

|

-

|

-

|

-

|

94

|

-

|

|

DSC Melting Point,℃

|

-

|

-

|

-

|

11

|

-

|

|

Application

|

Tubular film

|

Tubular film

|

Film

|

Film

|

Film

|

|

Grades

|

LDPE-2420D

|

LDPE-1C7A

|

LD605

|

LD100BW

|

LDPE1l50A

|

|

Density,g/cm³

|

0.9225

|

0.918

|

0.922

|

0.923

|

0.923

|

|

MFR,g/10min

|

0.25

|

7

|

6

|

2.1

|

50

|

|

Stretching broken column nominal strain,%

|

-

|

-

|

100

|

-

|

-

|

|

Tensile strength at broken,

Mpa

|

10

|

-

|

8

|

11

|

6

|

|

Haze,%

|

<14

|

-

|

-

|

-

|

-

|

|

Fisheye(0.3mm-0.2mm),

qty/1200cm²

|

-

|

-

|

-

|

-

|

-

|

|

Swell ratio,/

|

-

|

1.7

|

-

|

-

|

-

|

|

Turbidity,%

|

-

|

-

|

-

|

-

|

-

|

|

Gloss,%

|

(20℃)>15

|

-

|

-

|

-

|

-

|

|

Film Thickness,μm

|

(60℃)50

|

-

|

-

|

-

|

-

|

|

Modulus of Elasticity,Mpa

|

240

|

-

|

-

|

-

|

-

|

|

Dart Impact Strength,g

|

-

|

-

|

-

|

-

|

-

|

|

Vicat Softening Point,℃

|

94

|

-

|

-

|

-

|

-

|

|

DSC Melting Point,℃

|

109

|

-

|

-

|

-

|

-

|

|

Application

|

Film,blow-molded hollow products

|

cardboard, packaging

|

civil detonators, pipes, plates and injection-molding products

|

Wire&Cable Grade

|

Artificial Flower Grade

|

If you are interested in our products, please click this “

button

” to tell us your needs, and we will send you our product catalog and quotation.

Hot Searches