- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YUGONG

-

Dimension(L*W*H):

-

1080*740*880mm

-

Name:

-

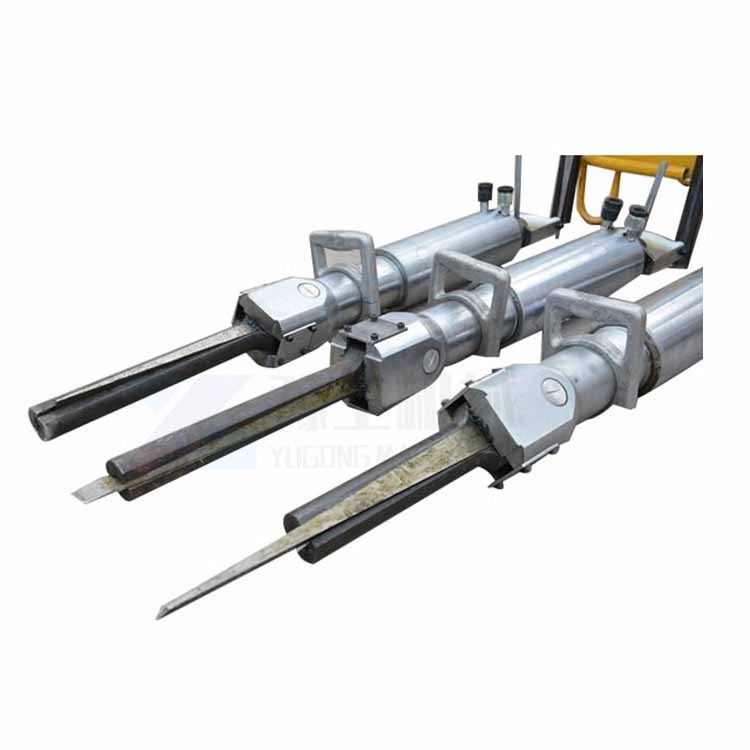

Hydraulic Rock Splitter

-

Product name:

-

Mobile Hydraulic Splitting Rock Splitter

-

Key word:

-

Hydraulic Rock Splitter Used

-

Usage:

-

Splite Rock, Concrete Crushing, Block Quarrying

-

Item:

-

Hydraulic Rock Breaker

-

Working Medium:

-

No. 46 or 68 antiwear hydraulic oil

-

Pump pack type:

-

Diesel Hydraulic Pump, Electric Oil Pump

-

Work pressure:

-

55-60Mpa

-

Splitting Diameter:

-

42-45mm

-

Wedge Length:

-

250/350/450mm

Quick Details

-

Weight (KG):

-

100

-

Application:

-

concrete rock splitter

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Dimension(L*W*H):

-

1080*740*880mm

-

Name:

-

Hydraulic Rock Splitter

-

Product name:

-

Mobile Hydraulic Splitting Rock Splitter

-

Key word:

-

Hydraulic Rock Splitter Used

-

Usage:

-

Splite Rock, Concrete Crushing, Block Quarrying

-

Item:

-

Hydraulic Rock Breaker

-

Working Medium:

-

No. 46 or 68 antiwear hydraulic oil

-

Pump pack type:

-

Diesel Hydraulic Pump, Electric Oil Pump

-

Work pressure:

-

55-60Mpa

-

Splitting Diameter:

-

42-45mm

-

Wedge Length:

-

250/350/450mm

Rock splitter for granite quarrying factory machine concrete breaking

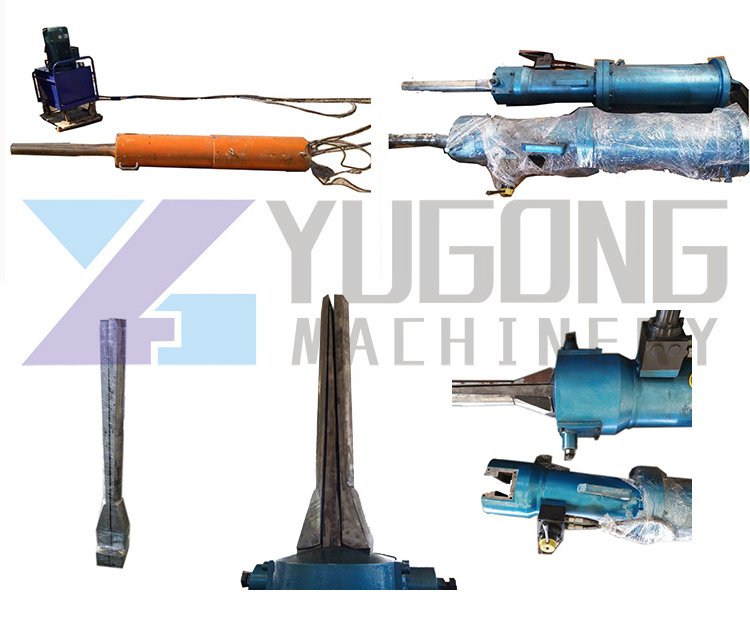

Yugong is specialized in the rock splitting machine, including the excavator mounted rock splitter and small hydraulic rock splitter . The hydraulic stone splitter machine is a tool to break rocks, split rocks.

It is mainly used for rock splitting and fragmentation, rock excavation, secondary rock or ore splitting, concrete splitting, tunnel excavation, underground mine excavation and extension, static blasting.

As well as quarry waste mining, marble, granite, sandstone and other stone excavation. First and second disintegration of large ore (metal ore, non-metal ore), mountain rock disintegration, quarry rock mining, partial and total dismantlement of large concrete construction, etc.

Large rock splitter is mainly used for rock splitting and fragmentation, rock excavation, secondary rock or ore splitting, tunnel excavation, underground mine excavation and extension, static blasting.

As well as quarry waste mining, marble, granite, sandstone and other stone excavation. First and second disintegration of large ore (metal ore, non-metal ore), mountain rock disintegration, quarry rock mining, partial and total dismantlement of large concrete construction, etc.

Like a small splitting machine, the huge rock splitter consists of hydraulic power station, splitting gun and a tubing. It is mainly used in large mines and quarries where explosives are not allowed to be used for primary and secondary disintegration of large ores or rocks.

| Model | YG-220 Rock Splitter | YG-280 Rock Splitter |

| Length | 3100mm | 3200mm |

| Drilling depth | >1500mm | >1700mm |

| Drilling diameter | 110-115mm | 130mm |

| Wedge length | 700mm | 1200mm |

| Crack width | 20mm | 25mm |

| Wedge diameter | 105mm | 125mm |

| Weight | 980kg | 1100kg |

Hydraulic splitter is widely used in quarry and mineral industry, construction engineering, demolition engineering, chemical industry, smelting production and overhaul engineering and various fields of emergency rescue.

1.

Quarrying and mineral industry

(exploitation of large wastes, division of large wastes, removal of large barren rock, etc.)

2. Construction Engineering (Tunnel Excavation, Subway Tunnel Excavation, Artificial River Excavation, Artificial River Excavation, Rock Channel Excavation, etc.)

3.

Demolition works

(demolition of concrete and reinforced concrete, demolition of old buildings, demolition of old piers, etc.)

4. Chemical, smelting production and overhaul projects (overhaul of smelting furnaces, demolition and construction of refractory bricks for various furnaces, etc.)

5. All kinds of rescue and disaster relief (earthquake, mine disaster, etc. clearance work, traffic accident rescue work.)

In the operation of airborne large-scale rock splitter, one rig (drilling 100-110 mm holes) and one excavator are needed. Splitter guns can also be driven by excavator pressure.

Method of operation:

First

, the

excavator

is used to clean the surface of roadbed stone and the soil between rock and rock to increase the overhead surface of rock.

Then

the drilling equipment is used to drill holes in the horizontal direction of the overhead surface or in the stratified position of the rock. The holes are drilled in the same cross-section. The distance between the holes is about 1.5-2 meters from the overhead surface, and the distance between the holes is controlled within 1.5-2.5 meters.

After drilling

, the splitting gun is hoisted by the digger and placed in the pre-drilled hole to determine the splitting direction and open the power for splitting.

Notes:

1. Manual rotary valve should prevent dust from entering, but once the phenomenon of reversing obstruction occurs, it should be cleaned with gasoline and diesel oil before use.

2. The impurities in the middle of the splitting blocks should be removed from time to time.

3. After a long period of use, the splitter will be deformed at the joint with the gun body chute. We should pay attention to it when using, but when the movement is not flexible, we should use a polishing machine to repair it until it is not blocked.

4. Check the spring force of the splitter fixed spring regularly. If the spring force is not enough, replace it.

5. Minimize the disassembly of the oil nozzle to avoid the impurities entering the gun body to damage the seals.

1. Wrapped by protective film;

2. Packed by standard import & export wooden cases or carton boxes;

3. Customized according to your requirement.

Delivery Time

Within one week

Shipping

Port

: Tianjin, Qingdao, Shanghai,Guangzhou or other ports according to your requirements.

Sea freight

: FOB/CIF/DDU quotation are all available.

Transport method

: By logistics; by automobile; by train; by shipping; by air etc.