Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Supplier Type:

-

OEM

-

Product name:

-

PCBA Board Assembly

-

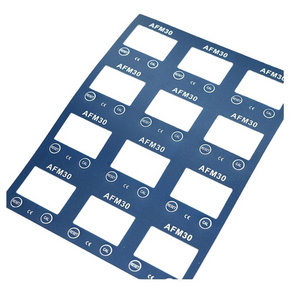

Surface Finishing:

-

HASL\OSP\immersion Gold

-

Solder mask color:

-

Blue.green.red.black.white.etc

-

Base Material:

-

FR4/ROGERS/Aluminum/High TG

-

Board Thickness:

-

0.2mm-7.0mm

-

Layer:

-

1-58 Layers

-

Application:

-

Electronic Products

-

Service:

-

One-stop Turnkey Service

-

Certificate:

-

ISO9001/Iso14001/CE/ROHS

Quick Details

-

Model Number:

-

PCBA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YYFab

-

Supplier Type:

-

OEM

-

Product name:

-

PCBA Board Assembly

-

Surface Finishing:

-

HASL\OSP\immersion Gold

-

Solder mask color:

-

Blue.green.red.black.white.etc

-

Base Material:

-

FR4/ROGERS/Aluminum/High TG

-

Board Thickness:

-

0.2mm-7.0mm

-

Layer:

-

1-58 Layers

-

Application:

-

Electronic Products

-

Service:

-

One-stop Turnkey Service

-

Certificate:

-

ISO9001/Iso14001/CE/ROHS

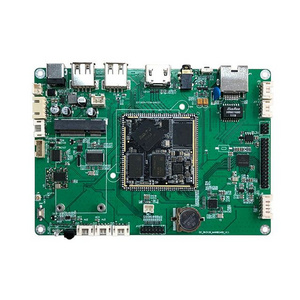

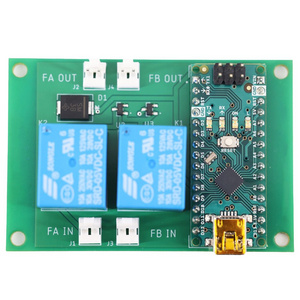

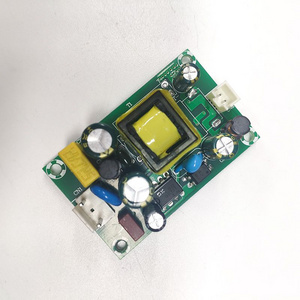

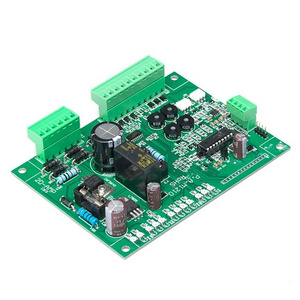

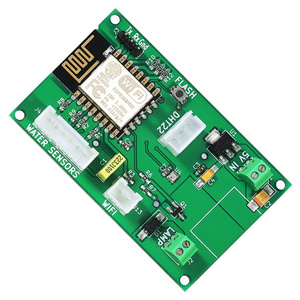

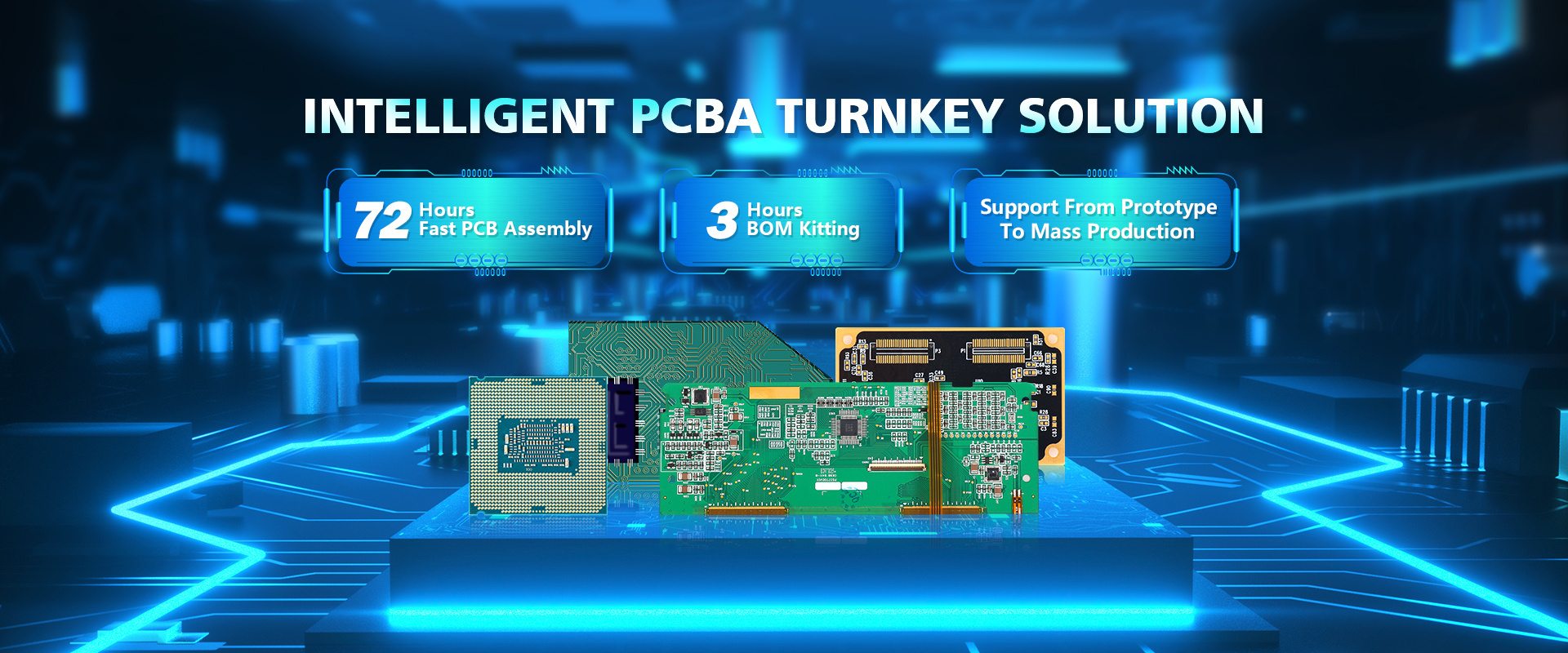

Products Description

Allchips can do: one-stop service

Fast PCB Fabrication for Samples and Mass Production

Electronic Components Sourcing Services

PCBA Assembly Services :SMT,DIP,BGA...

Flying Probe Test, X-ray Inspection, AOI Test,Function Test

Stencil,Cable and Enclosure Assembly

Reverse engineering service

1. Gerber file and Bom list

2. Clear quantity of pcba or pcba sample for us

3. Test method for PCBA

"gerber files", " *.pcb", " *.PcbDoc ", EAGLE " *.brd ", " *.lay" and " *.lay6" files.

Gerber file is the best if possible.

|

Item (PCB Assembly)

|

One-Stop OEM Service

|

|

Max Board Size

|

680*550mm Smallest:0.25"*0.25"

|

|

Min Components size

|

0201-54 sq.mm (0.084 sq.inch),Long Connector,CSP,BGA,QFP

|

|

Speed

|

0.15sec/chip, 0.7sec/QFP

|

|

Wave-Solder

|

Max.PCB Width:450mm

|

|

|

Min.PCB Width:unlimited

|

|

|

Components Height:Top 120mm/Bot 15mm

|

|

Sweat-Solder

|

Metal Types:Part,Whole,Inlay,Side-step

|

|

|

Metal Material:Copper,Aluminum

|

|

|

Surface Finish:Plating Au,Plating Silver,Plating Sn

|

|

|

Air Bladder Rate:less than 20%

|

|

Assembly Types

|

SMT and Thru-hole

|

|

Solder Type

|

Water Soluble Solder Paste,Leaded and Lead-Free

|

|

File Formats

|

Bill of Materials ,Gerber Files,Pick-N-Place Files(XYRS)

|

|

Type of Service

|

Turn-Key,Partial Turn-Kye or Consignment

|

|

Assembly details

|

SMT and Thru-hole, ISO SMT and DIP lines

|

|

Component Packaging

|

Cut Tape,Tube Reels Loose,Parts

|

|

Testing

|

XRAY Inspection,AOI Testing ICT,Flying Probe,Burn-in,Function Test

|

|

Turn Time

|

1-15 Days

|

|

Layers: 1 & 2 & 4 Qty: 10 pcs

Material: Rigid FR-4 Size: Within 100*100 mm Assembly Parts: Within 20 pcs |

|

|

What is needed for PCBA quotation?

|

1.Gerber file & Bom list.

2.Clear pics of pcba or pcba sample for us.

3.Test method for PCBA. |

|

PCB+ assembly process

|

Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity

|

---PCBA SERVICE FOR PRINTED CIRCUIT BOARD ASSEMBLY

---ONE-STOP PURCHASING SERVICE

---All BOM Service Included In One Box

---ONE-STOP PURCHASING SERVICE

---All BOM Service Included In One Box

PCBA SMT

Cost advantage

Own PCB board, circuit board, SMT patch factory

Top 5 electronic components platform

Fast delivery

PCB, SMT urgent service

24 H + 24 h, finished PCBA processing

Quality Assurance

ISO9001:2015 quality management

TS16949 automotive parts manufacturing certification

International experience

10 years of PCBA manufacturing experience,

Serving listed companies in more than 100 countries and domestic

Own PCB board, circuit board, SMT patch factory

Top 5 electronic components platform

Fast delivery

PCB, SMT urgent service

24 H + 24 h, finished PCBA processing

Quality Assurance

ISO9001:2015 quality management

TS16949 automotive parts manufacturing certification

International experience

10 years of PCBA manufacturing experience,

Serving listed companies in more than 100 countries and domestic

PCBA foundry material

Design DFM optimization

Efficient PCB manufacturing

Precise BOM distribution

Flexible SMT processing

Efficient PCB manufacturing

Precise BOM distribution

Flexible SMT processing

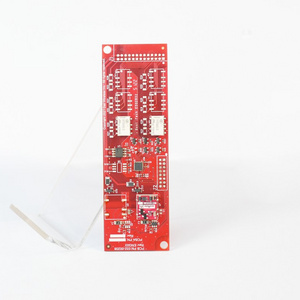

SMT Processing

Minimum 01005 and 0.2mm BGA

Maximum 1300*460mm patch size

4 million points/day processing capacity

Regular RC spot inventory

Fastest delivery of PCBA in 6 hours

Maximum 1300*460mm patch size

4 million points/day processing capacity

Regular RC spot inventory

Fastest delivery of PCBA in 6 hours

Precision PCB manufacturing

2~64 layer multi-layer PCB capability

High TG board, high frequency PCB

HDI PCB, thick copper plate

FPC board, soft and hard board

From sample to batch manufacturing

For PCBA : PCB information, BOM,Testing documents.

High TG board, high frequency PCB

HDI PCB, thick copper plate

FPC board, soft and hard board

From sample to batch manufacturing

What is needed for PCB & PCBA quotation?

For PCB

: Quantity, Gerber file and technical requirements(material,size, surface finish treatment, copper thickness,board

thickness).

thickness).

For PCBA : PCB information, BOM,Testing documents.

Recommend Products

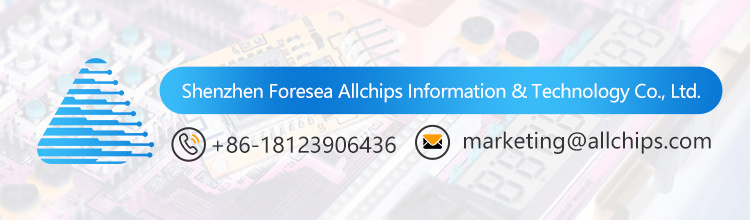

Contact Us

About Us

With more than 15 years experience in electronic components supply chain, now Allchips has been the top 5 electronic components platform in China, specializing in BOM Kitting and PCBA turnkey solution.

Supported by over 1500 authorized distributors, our strong brands including:TI, ST, NXP, Microchip, Maxim, ADI, Panasonic, Yageo, AVX, ON, etc.

Allchips would be glad to assistant your project from prototype to mass production with the professional supply chain solutions of electronic components.

Allchips is equipped with a 2000 square meter dust-free production workshop, Yamaha automatic SMT machine, 3D-SPI (solder paste inspection) machine, AOI, X-ray, BGA reworks station, and other equipment. With the advantages of advanced manufacturing equipment, intelligent MES management system, and engineering & technical support, We offers high-quality and high-demand one-stop PCBA intelligent manufacturing services including the prototype, trial production, and mass production. Allchips aims to become your powerful online smart factory to improve your production efficiency and reduce product lead time.

Our Advantages

PCBA Production Process

FAQ

Q1. What is needed for quotation?

1.Gerber file & Bom list.

2.Clear pics of pcba or pcba sample for us.

3.Test method for PCBA.

3.Test method for PCBA.

Q2. What file formats do you accept for production?

Gerber file:CAM350 RS274X

PCB file: Protel 99SE, P-CAD 2001 PCB

BOM: Excel(PDF, WORD, TXT)

Q3. Are my files safe?

Your files are held in complete safety and security. We protect the intellectual property for our customers are never shared with any third parties.

Q4. MOQ?

There is no MOQ in PCBAonline. We are able to handle small as well as large volume production with flexibility.

Q5. Shipping cost?

The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need us to quote you the freight.

Q6. How can you ensure the quality of the PCBs?

Our PCBs are 100% test including Flying Probe Test, E-test and AOI.

Q7. Can we visit your company?

Hot Searches