- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Different Models

-

Weight:

-

610 KG

-

Warranty:

-

2 Years

-

Marketing Type:

-

NEW

-

Warranty of core components:

-

2 years

-

Core Components:

-

Main parts

-

Product name:

-

Jig Separator

-

Application:

-

gold, alluvial mineral, barite, manganese ore etc.

-

Quality:

-

high reputation

-

Feeding Density:

-

30%~50%

-

After sale service:

-

Online support,Field installation,Commissioning,training

-

Certification:

-

ISO9001:2008

Quick Details

-

Production Capacity:

-

99%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Gelin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Different Models

-

Weight:

-

610 KG

-

Warranty:

-

2 Years

-

Marketing Type:

-

NEW

-

Warranty of core components:

-

2 years

-

Core Components:

-

Main parts

-

Product name:

-

Jig Separator

-

Application:

-

gold, alluvial mineral, barite, manganese ore etc.

-

Quality:

-

high reputation

-

Feeding Density:

-

30%~50%

-

After sale service:

-

Online support,Field installation,Commissioning,training

-

Certification:

-

ISO9001:2008

Coal wash plant jig machine for coal washing and other ores separating

dressing, such as tungsten, tin, gold,ilmenite, hemtite,rutile sand etc. The maximum feeding particle size is 6-25mm and can be reach 30mm in producing sand ore process.Our jig machine adopts advanced jig technology, reach the leading level.

Gelin Supply two types:one is

saw-tooh wave jigger;

another one is

hydraulic radial jigger.

Sawtooth Wave Jigger

Traditional Sawtooth Wave jigger

is screen fixed type machine that realizes the separation of light and heavy mineral by the different sedimentation speed in vertical alternating water flow, it mainly used to handle placer gold,tungsten, tin, hematite and beach placer and other minerals.

We have different models meet different requirements:

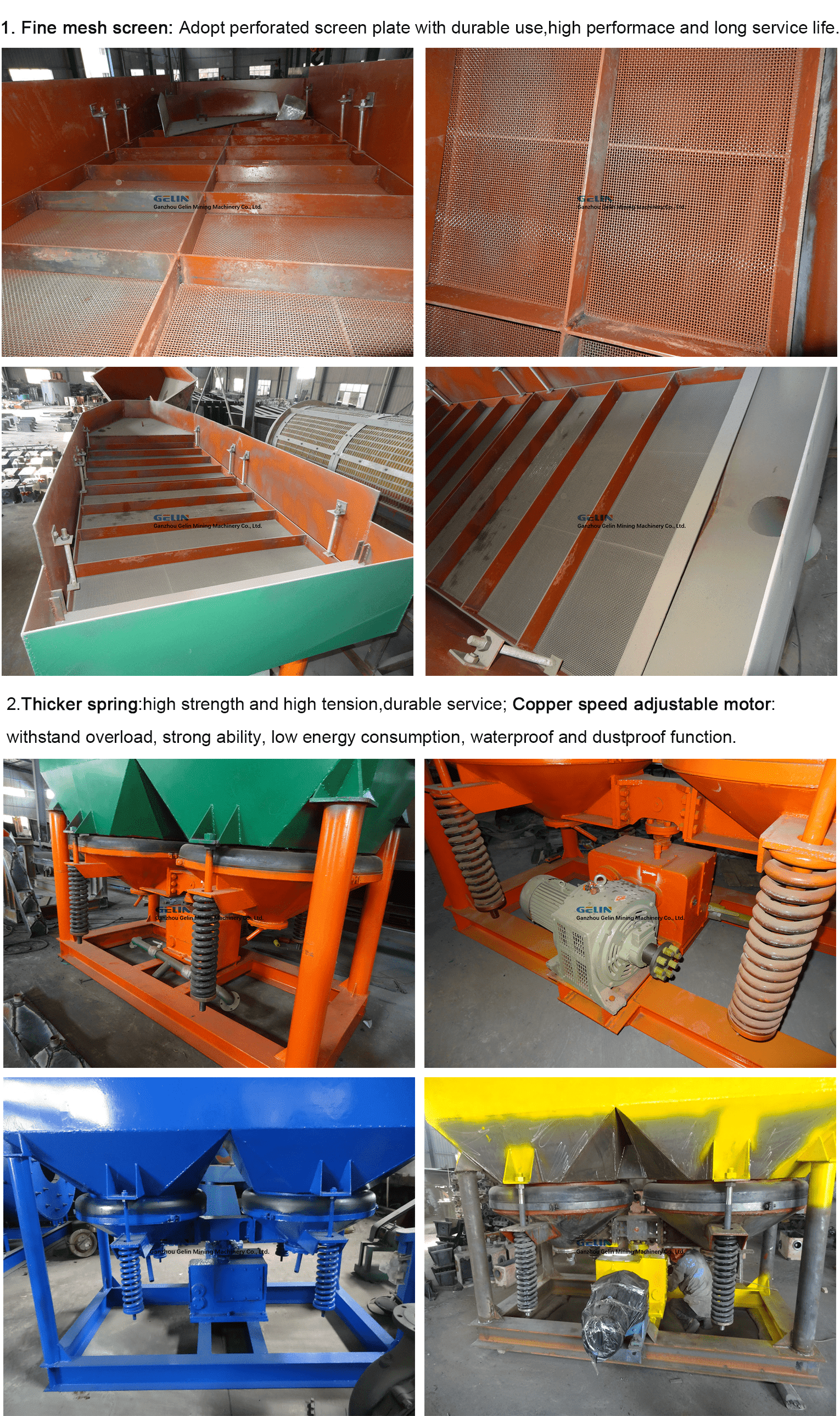

Features

1.Stroke and jig frequency are easy to adjust,The advanced frequency conversion speed control technology is convenient to operateand manage.

2.Small cover area, high processing capacity per unit area.

3.Suitable for a wide range of particle size because of large processing capacity.

4.More saving water (around 30%-40%)than other normal jigger.

5.High recovery rate and easy to change spare parts and maintain.

2.Small cover area, high processing capacity per unit area.

3.Suitable for a wide range of particle size because of large processing capacity.

4.More saving water (around 30%-40%)than other normal jigger.

5.High recovery rate and easy to change spare parts and maintain.

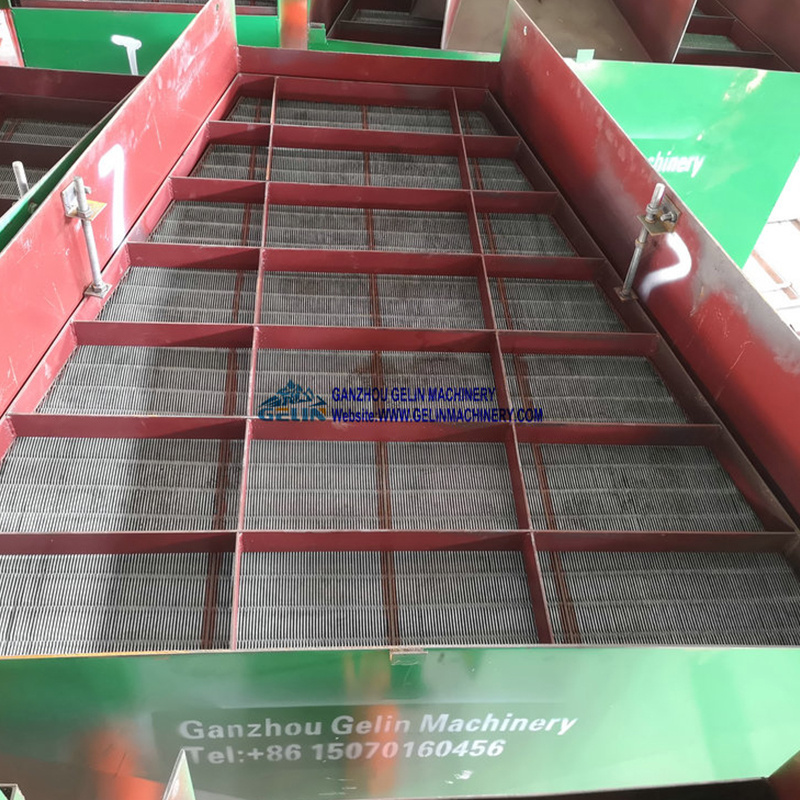

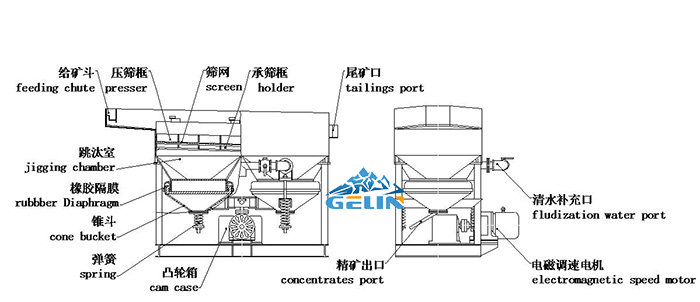

Saw-tooth wave Jigger mainly includes three parts:Main Frame, Driving set and Jigging Chamber.

Below is some detailed pictures:

|

Parameter for saw-tooth wave jigger

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Model

|

Charmber

|

|

Feeding Size

|

Adding Water Yield Under Screen

|

Water Pressure

|

Handling Capacity

|

Motor Power

|

Dimension

|

Weight

|

|||||||||

|

|

Shape

|

Area (㎡)

|

mm

|

m³/t

|

MPa

|

t/h

|

kw

|

mm

|

kg

|

|||||||||

|

JT0.57-1

|

Ladder

|

0.57

|

6

|

1-3

|

≧0.05

|

1-2.5

|

1.5

|

1550x780x1530

|

610

|

|||||||||

|

JT1-1

|

Ladder

|

1.04

|

10

|

1-3

|

|

2-4

|

2.2

|

2270x1110x1890

|

900

|

|||||||||

|

JT1.5-2

|

Rectangle

|

1.53

|

10

|

1-2

|

|

3-8

|

3

|

3200x1550x2050

|

1520

|

|||||||||

|

JT2-2

|

Rectangle

|

2.28

|

10

|

1-3

|

|

4-8

|

3

|

3225x1550x2050

|

1640

|

|||||||||

|

JT3-1

|

Ladder

|

3.3

|

10

|

1-3

|

|

6-10

|

5.5

|

3180x2000x2600

|

3260

|

|||||||||

|

JT4-2

|

Rectangle

|

4.33

|

30

|

1-3

|

|

10-15

|

7.5

|

3600x1850x2600

|

4600

|

|||||||||

|

JT5-2

|

Ladder

|

4.86

|

10

|

1-3

|

|

10-15

|

7.5

|

3600x2000x2600

|

4500

|

|||||||||

|

JT1.5-2S

|

Rectangle

|

1.53

|

30

|

1-3

|

|

3-8

|

1.5x2

|

3200x1550x2050

|

1590

|

|||||||||

|

JT2-2S

|

Rectangle

|

2.28

|

30

|

1-3

|

|

4-8

|

3x2

|

3225x1550x2050

|

1700

|

|||||||||

|

JT3-2S

|

Rectangle

|

3

|

30

|

1-3

|

|

6-15

|

5.5x2

|

3560x2030x2600

|

3260

|

|||||||||

|

JT4-2S

|

Rectangle

|

4.33

|

30

|

1-3

|

|

10-20

|

4x2

|

3600x1850x2600

|

4660

|

|||||||||

|

JT5-2S

|

Ladder

|

4.86

|

30

|

1-3

|

|

10-20

|

5.5x2

|

3600x2000x2600

|

4700

|

|||||||||

|

JT6-3S

|

Rectangle

|

6

|

30

|

1-3

|

|

15-30

|

7.5x2

|

4600x2000x2600

|

5900

|

|||||||||

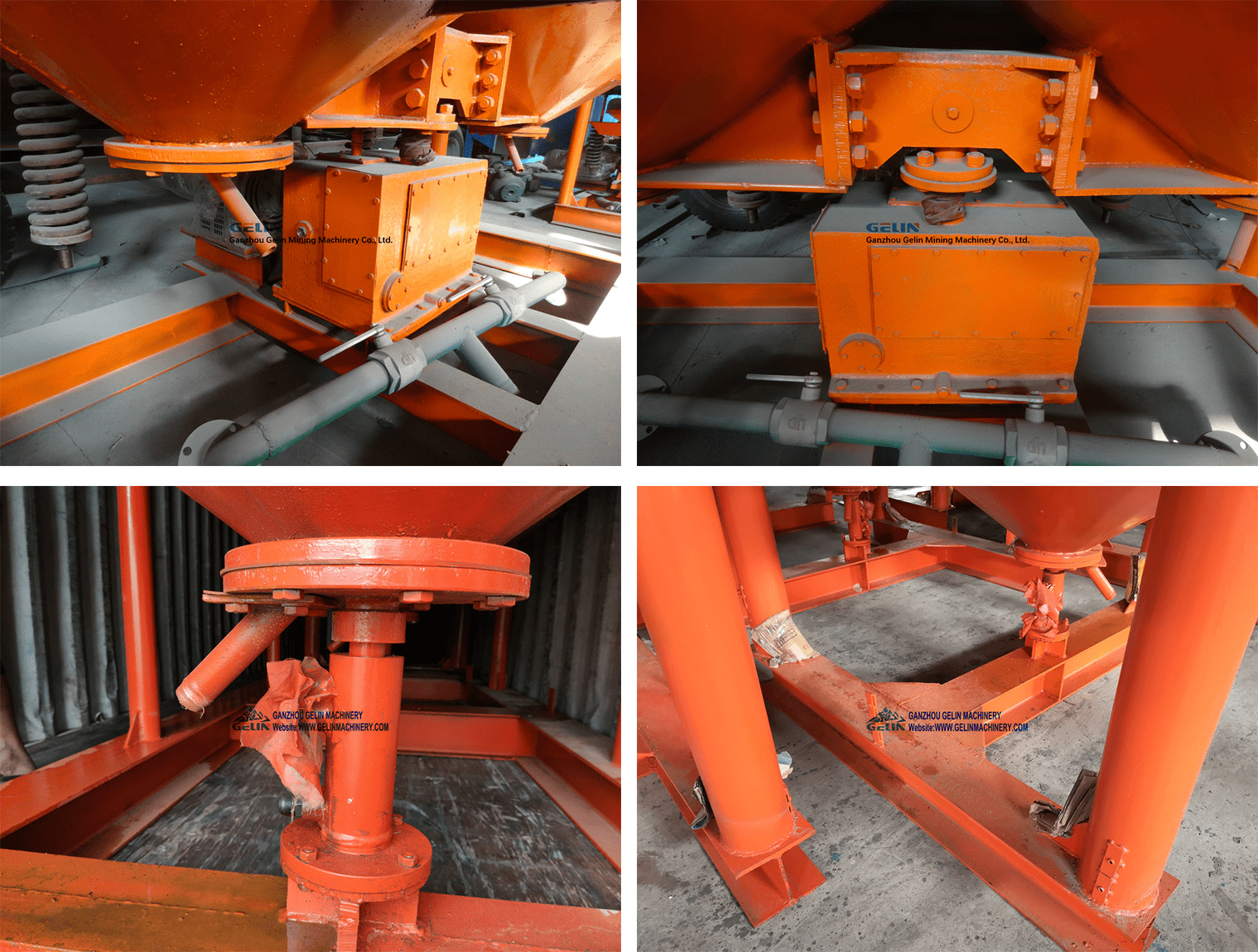

Hydraulic Radial Jigger

Hydraulic radial jig

is developed from circular jig. It's composed of two parts:

drive and tank

. The drive is mechanical hydraulic type, the power is provided by motor through the transmission mechanism let the output shaft of the gear reducer drives the cam rotation, the cam pushes the piston of each master cylinder make periodic reciprocating motion, which converts electrical energy into mechanical energy and then into hydraulic energy. Through hydraulic pipes and all kinds of valves let the moving cylinder drives the cone of jig up and down fluctuation.

Hydraulic radial jig adopts electromagnetic speed regulating asynchronous motor to realize the frequency adjustment, it's a step-less adjustment and the adjustable range of jig frequency is 0-90 times per minute. Hydraulic radial jig has many advantages compared with the various jig machines: Big jigging area, big capacity; because the jig tank is fan-shaped, it is advantageous to recover fine particle materials; Compact structure, central feeding and small distribution space, suitable for use on dredger; Because of the hydraulic drive, the transmission mechanism is simplified and saving power. The total power of the same process capacity is only 11.6 Kw, saving about 55% power than the conventional jig machine in the same concentration area. The pulsation curve is approximation saw-tooth curve, not only conducive to recover fine heavy minerals, also saving a large number of make-up water, the make-up water is about a quarter of the ordinary jig.

Advantages

1. Big capacity, less land occupation, wide recover range on size

2. High concentrating ratio and high recovery

3. Easy to install, operate and maintain

4. The pulsation curve is saw-tooth wave shape facilitate heavy mineral to settling

5. Saving water 60-70% and saving power 55% than the ordinary jig

6. The pulsation speed very easily adjusted by the regulator

7. Can achieve a good result in processing such as placer gold, tungsten, tin, hematite, manganese, barite, and gemstone etc.

2. High concentrating ratio and high recovery

3. Easy to install, operate and maintain

4. The pulsation curve is saw-tooth wave shape facilitate heavy mineral to settling

5. Saving water 60-70% and saving power 55% than the ordinary jig

6. The pulsation speed very easily adjusted by the regulator

7. Can achieve a good result in processing such as placer gold, tungsten, tin, hematite, manganese, barite, and gemstone etc.

|

Parameter for hydraulic radial jigger

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Chamber

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

11

|

|||||||||

|

Jigging area (m3)

|

9.9

|

13.2

|

16.5

|

19.8

|

23.1

|

26.4

|

29.7

|

3.3

|

36.3

|

|||||||||

|

Stroke (mm)

|

20. 25. 30

|

|

|

|

|

|

|

|

|

|||||||||

|

Frequency of stroke (r/min)

|

50-85

|

|

|

|

|

|

|

|

|

|||||||||

|

Feeding size (mm)

|

<25

|

|

|

|

|

|

|

|

|

|||||||||

|

Make-up water (m3/t)

|

1-3m3/ton of ore

|

|

|

|

|

|

|

|

|

|||||||||

|

Make-up water pressure (Mpa)

|

≥0.10

|

|

|

|

|

|

|

|

|

|||||||||

|

Capacity (t/h)

|

50-75

|

66-100

|

78-125

|

100-150

|

116-175

|

132-197

|

150-200

|

166-245

|

182-270

|

|||||||||

|

Driving motor (kw)

|

5.5

|

7.5

|

7.5

|

7.5

|

11

|

11

|

11

|

15

|

15

|

|||||||||

|

hydraulic power unit (kw)

|

0.55

|

|

|

|

|

|

|

|

|

|||||||||

|

Weight (kg)

|

6000

|

8000

|

10000

|

12500

|

14200

|

15800

|

17500

|

18000

|

19200

|

|||||||||

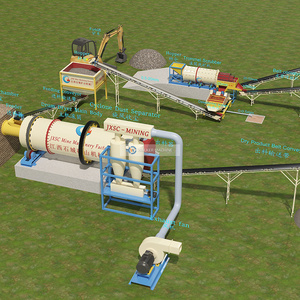

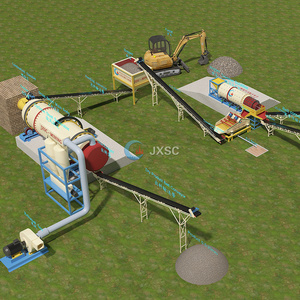

Application&Successful Case

Mining condition:

River sand type tin mining.

Our company design turn key process plant for 5000 tons per day.

The customers get high grade tin ore from very low grade a fter use our equipments.

Below are Tin mining process flowchart and other mining site pictures for jig machines:

Packing & Delivery

Packing

Normally the machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below:

1.

Nude packing.

2.

Bundle packing.

3.

Grass rope packing.

4.

Water proof packing.

5.

Wooden pallets packing.

6.

Wooden box or carton box packing.

Delivery

Usually the equipments are delivered aboard by

tracks,trains,or container(sea transportation). and some spare parts or very small goods also support to send by express

, our company have built good relationships with large cargo agent and shipping companies which guarantee our products delivered safely and promptly.Sea transportation includes three delivery ways as below:

1.

40HQ container

: used for goods without overlength, overheight and overweight;

2.

FR(Flat Rack) container

:suitable for large equipments with overlength,overheight like ball mill,excavator,etc.

3.

Bulk cargo shipment (LCL)

: used for some goods without loading in full container,normally it requires good packing with marks for safety and easy to be trackable.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

About Company

Ganzhou Gelin Mining Machinery Co., Ltd

is an over 30 years professional

manufacturer and exporter of mining machinery for crushing, screening, grinding, flotation, separation etc. in China.

Gelin have a complete service system which can provide customer full service in mining field and after sales service.By now, Gelin’s equipments and services are exported to over 60 countries,include America, Russia, India, Africa, Brazil, Chile,South Africa,Zambia etc.

Sincerely welcome customers to visit our factory.

Our Services

One Stop solution for beneficiation plant service:

1.Engineering consulting available,it makes clients have a comprehensive understanding of beneficiation plant,including mine value,useful elements,mineral processing technology,plant scale,essential equipments,etc.

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings.

2.Arrange mineral beneficiation experiment after received the material sample and beneficiation test report will be done after test.

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings.

4.Manufacturing the necessary equipments and arrange the shipment.

5.Complete services for Installation and commissioning and technical training(operating training,common problem solving training).

After-sale Service

Regularly visit customers to provide after- sale

technical supports and to solve problems of beneficiation plant. For equipments supplied,we could provide one-year warranty and provide spare parts with preferential price in the long term and be responsible for any problems with the them.

FAQ

Q:

Are you a trading company or a factory?

A:

We are a factory at Shicheng county with 110 workers,6 workshops covered 17,000㎡ and office covered 2,500㎡. Welcome to visit our factory at anytime.

Q:

What is your payment terms?

A: By TT( Telegraphic Transfer ) , 100% or 40% Deposit before production and 60% balance payment will be paid off after sending product pictures and before loading from factory.

A: By TT( Telegraphic Transfer ) , 100% or 40% Deposit before production and 60% balance payment will be paid off after sending product pictures and before loading from factory.

Q: How long is the guarantee period of your products?

A:

The guarantee period is 1-2 years, pls ask staff for more details. And we will supply lifelong technical support service and the spare parts at lowest cost.

Q:

Is it possible to produce customized products

?

A: Yes, most of our products are produced as required.

A: Yes, most of our products are produced as required.

Q:

Is it possible to provide sample for your factory to do ore-dressing experiment?

A: Yes, engineering consulting is available and we’d like to arrange mineral beneficiation experiment after received your sample and provide the test report.

A: Yes, engineering consulting is available and we’d like to arrange mineral beneficiation experiment after received your sample and provide the test report.

For more details, please refer to our website:

www.gelinmachinery.com

Related Products

Hot Searches