- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1600

-

Driven Type:

-

Multi-Function Packaging Machine, Mechanical

-

Voltage:

-

220V/380V

-

Place of Origin:

-

China, Zhejiang China

-

Brand Name:

-

hanbeter

-

Dimension(L*W*H):

-

1710*1505*1640mm

-

customization:

-

yes

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Factory:

-

YES

-

Payment item:

-

TT30 % down70% balance before shipping

-

Certification:

-

CE/ISO9001

-

Machine Material:

-

Stainless steel

-

Installation:

-

7 days/engineer with trainning

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, COATING, Sealing

-

Packaging Type:

-

Stand-up Pouch, Bags, Film, Pouch

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

1600

-

Driven Type:

-

Multi-Function Packaging Machine, Mechanical

-

Voltage:

-

220V/380V

-

Place of Origin:

-

China, Zhejiang China

-

Brand Name:

-

hanbeter

-

Dimension(L*W*H):

-

1710*1505*1640mm

-

customization:

-

yes

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Factory:

-

YES

-

Payment item:

-

TT30 % down70% balance before shipping

-

Certification:

-

CE/ISO9001

-

Machine Material:

-

Stainless steel

-

Installation:

-

7 days/engineer with trainning

| Product Features | |

| customization | yes |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Dimension(L*W*H) | 1710*1505*1640mm |

| Factory | YES |

| Warranty of core components | 1 Year |

| Function | FILLING, Wrapping, Labeling, COATING, Sealing |

| Key Selling Points | High Productivity |

| Voltage | 220V/380V |

| Packaging Material | Plastic, Paper |

| Machinery Test Report | Provided |

| Payment item | TT30 % down,70% balance before shipping |

| Installation | 7 days/engineer with trainning |

| Place of Origin | Zhejiang, China |

| Warranty | 1 Year, 1 year |

| Packaging Type | Stand-up Pouch, Bags, Film, Pouch |

| Showroom Location | Canada, Italy, South Korea, Bangladesh |

| Automatic Grade | Automatic |

| Certification | CE/ISO9001 |

| Brand Name | hanbeter |

| Type | Multi-Function Packaging Machine |

| Video outgoing-inspection | Provided |

| Driven Type | Mechanical |

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Farms |

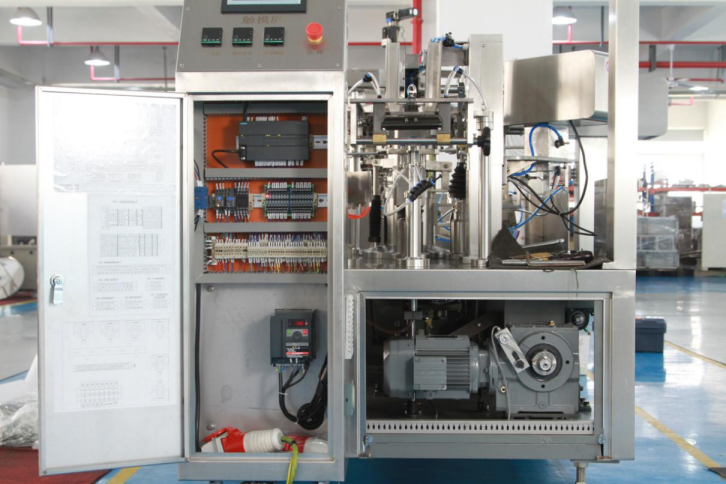

| Core Components | Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox |

| Production Capacity | 5bag/min, 20bag/min, 7bag/min, 6bag/min, 40bag/min, 25bag/min, 8bag/min, 10bag/min, 50bag/min |

| Machine Material | Stainless steel |

| After Warranty Service | Video technical support |

| Application | Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, Commodity |

|

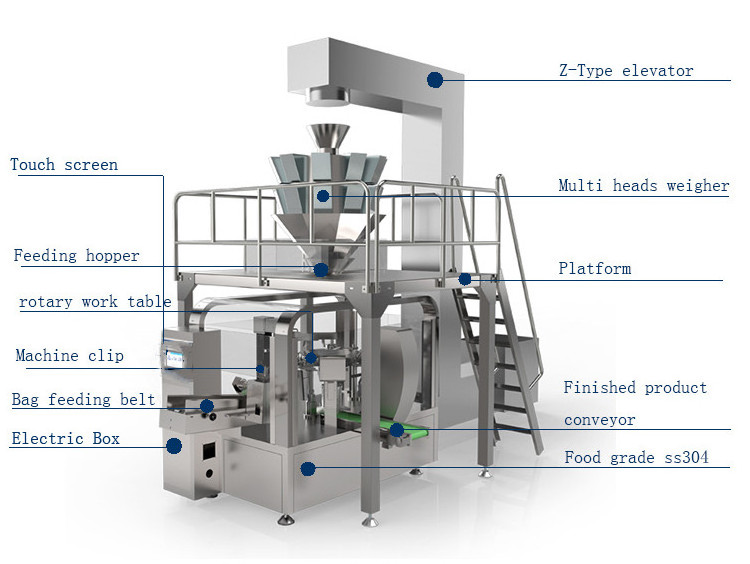

Specification for MingRui Rotary Pouch Packing machine

|

|||||||

|

Model

|

MR8-200

|

MR8-260R

|

MR8-300R

|

MR8-400R

|

|||

|

Bag Size

|

Width:100-210mm,

Length:100-350mm

|

Width:120-260mm, Length:120-350mm

|

Width:180-300mm

Length:180-400mm

|

Width:280-400mm, Length:280-650mm

|

|||

|

Filling Volume

|

5-2500g (Depending on type of products)

|

Max 5kgs

|

|||||

|

Capacity

|

30-60bags/min

(The speed depends on products and packaging material ) 25-45bags/min (For zipper bag) |

30-60bags/min

(The speed depends on products and packaging material ) 25-45bags/min (For zipper bag) |

30-40bags/min

(The speed depends on products and packaging material ) |

20-30bags/min

(The speed depends on products and packaging material ) |

|||

|

Package Accuracy

|

Error≤±1%

|

||||||

|

Total Power

|

4 KW (220V-450V, 3PH, 50HZ/60HZ

|

||||||

|

Demension

|

1460×2500×1400mm

|

1710x1505x1640mm

|

2460×1830×1460mm

|

2520×1750×1600mm

|

|||

|

Weight

|

1700 KGS

|

||||||

|

Main Standard Accessories

|

1. Bag feeding system 2. PLC control system 3. Bag opening device 4. Filling system

5. Cleaning system 6. Hot

sealing control system 7. Output system

|

||||||

|

Main Optional Equipment

|

Material metering and filling machine, working platform, check weigher, material elevator, finished product conveyor, metal detector.

|

||||||

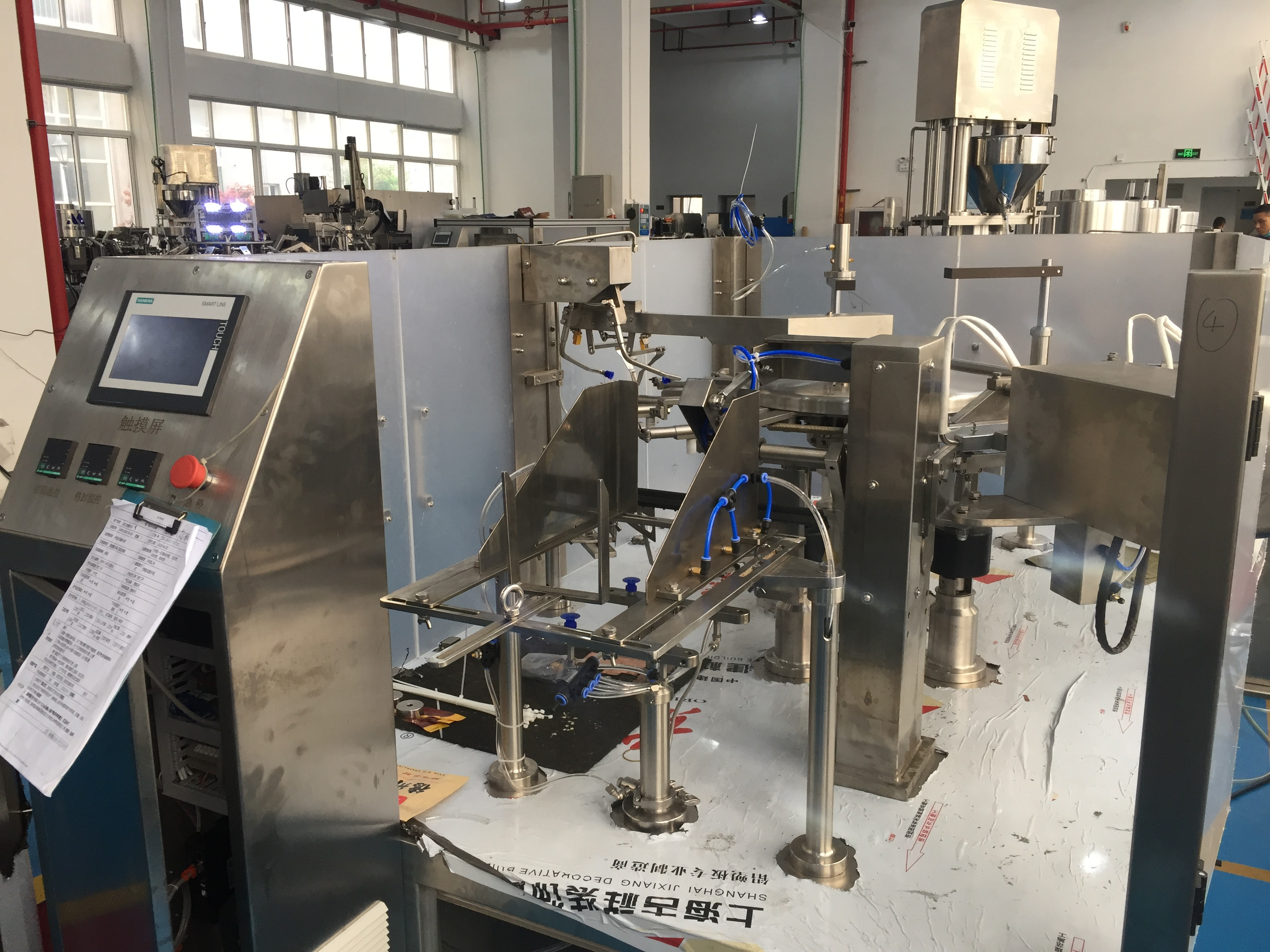

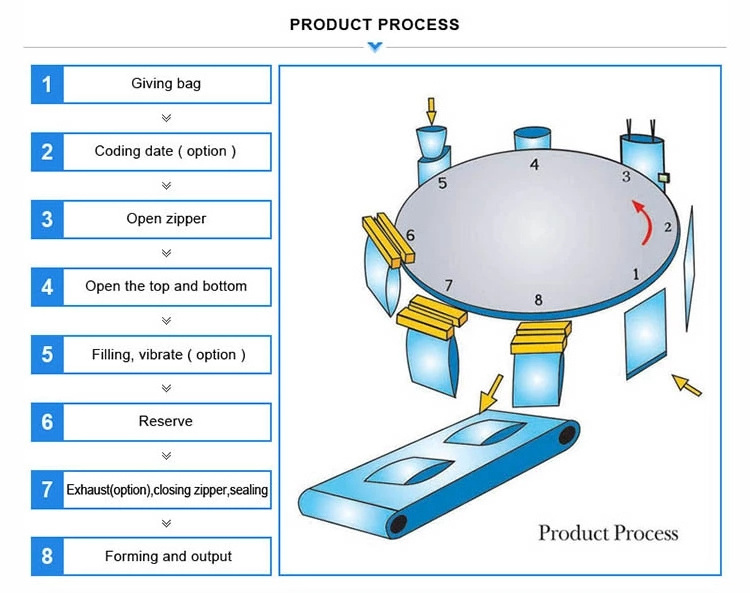

Features and Characteristics:

1. Easy to operate: PLC controller, HMI system, fault indication on the touch screen. 2. Easy to adjust: All working process in one station, more easily adjusting. 3. Frequency control: Speed can be adjusted by frequency conversion within the range. 4. High Automation: Unmanned in weighing and packing process, machine will show alarm automatically when failure. 5. Pouch size change: 8 sets of gripper can be adjusted hand wheel at one time . 6. No pouch/ incorrect pouch opening-no fill-no seal, machine alarm. 7. Machine will show alarm and stop when inadequate air pressure. 8. Safety guards with safety-switches, machine alarm and stop when the safety guards are opened. 9. Hygienic construction, the product contact parts are adopted sus304 stainless steel. 10. Imported engineering plastic bearings, no need oil, no contamination. 11. Oil-free vacuum pump, avoid the pollution of the production environmental.

Work Process:

bag giving→date coding →bag opening →filling and vibrating 1→filling and vibrating2→heat sealing 1→heat sealing 2→forming and output

Suitable Bag Type:

All types of heat sealable performed side seal bags, block bottom bags, zip-lock bags, stand-up pouch with or without spout etc. Please send us your bag pictures , we have the suitable packing machines always .

All types of heat sealable performed side seal bags, block bottom bags, zip-lock bags, stand-up pouch with or without spout etc. Please send us your bag pictures , we have the suitable packing machines always .

Machine Details :

Related Equipments :

Weighing system- For measuring the weight of the products , we will help you choose suitable weigher according the product features.

Multi head weigher

Linear Weigher

Volumetric Cup Weigher

Related Equipments :

Elevator- For feeding the products from the floor to the weigher/machine, we will help you choose the suitable elevator according your products .

Z Type Elevator

Suitable for grain products

Incline Elevator

Suitable for irregular products

FAQ

Hot Searches