- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Custom local voltage

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

450000

-

Kinds of Coating:

-

Liquid Roller Coating

-

Coating Color:

-

Multi Color

-

Coil Material:

-

GI, GL, Aluminum Alloy, Hot rolled Aluminum

-

Install Location:

-

Customer Location

-

Advantage:

-

Environmental Protection

-

Line Speed:

-

Max 200 m/min

-

Coating Film:

-

PE, PU, PVC, VCM, PCM

-

Application:

-

Home Appliance, Construction Material, Building Material

-

Control System:

-

PLC+Touch Screen Automatic

-

Certification:

-

CE ISO9001

Quick Details

-

Machine Type:

-

Color Coating Line, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Drying Oven, Curing oven, Coating Equipment, Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WEIFANG JINGXIANG

-

Voltage:

-

Custom local voltage

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

450000

-

Kinds of Coating:

-

Liquid Roller Coating

-

Coating Color:

-

Multi Color

-

Coil Material:

-

GI, GL, Aluminum Alloy, Hot rolled Aluminum

-

Install Location:

-

Customer Location

-

Advantage:

-

Environmental Protection

-

Line Speed:

-

Max 200 m/min

-

Coating Film:

-

PE, PU, PVC, VCM, PCM

-

Application:

-

Home Appliance, Construction Material, Building Material

-

Control System:

-

PLC+Touch Screen Automatic

-

Certification:

-

CE ISO9001

Product Description

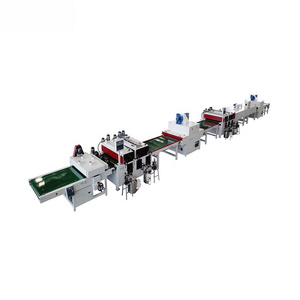

Color coating steel sheet production line with roller coating machine for roof

The color coating plate is mainly based on cold rolled plate, galvanized steel plate and aluminum alloy plate. This kind of plate has advantages of corrosion resistance and decoration, as well as directly providing raw material for construction industry, automobile manufacturing, electric and others.

This color coating production line is used to produce color coating coil. It is practical, reliable and mature, client can produce stably and run in the long term, production capacity from 30,000 to 240,000 tons per year.

Product Specification

|

Raw Material:

|

Aluminum alloy coils, stainless steel coils, GI, GL, hot rolled aluminum coils, cold rolled annealed steel coils, etc.

|

|

Thickness:

|

0.2~2.0mm

|

|

Width:

|

650~1650mm

|

|

Designed Process Speed:

|

30~200m/min

|

|

Annual capacity:

|

30,000~240,000ton/year

|

|

Machine Color:

|

As client's requirements

|

|

Fuel:

|

Natural gas, LPG, electricity

|

|

Application:

|

Construction material, household appliance, building material, etc.

|

Detail Image

Sewing Machine

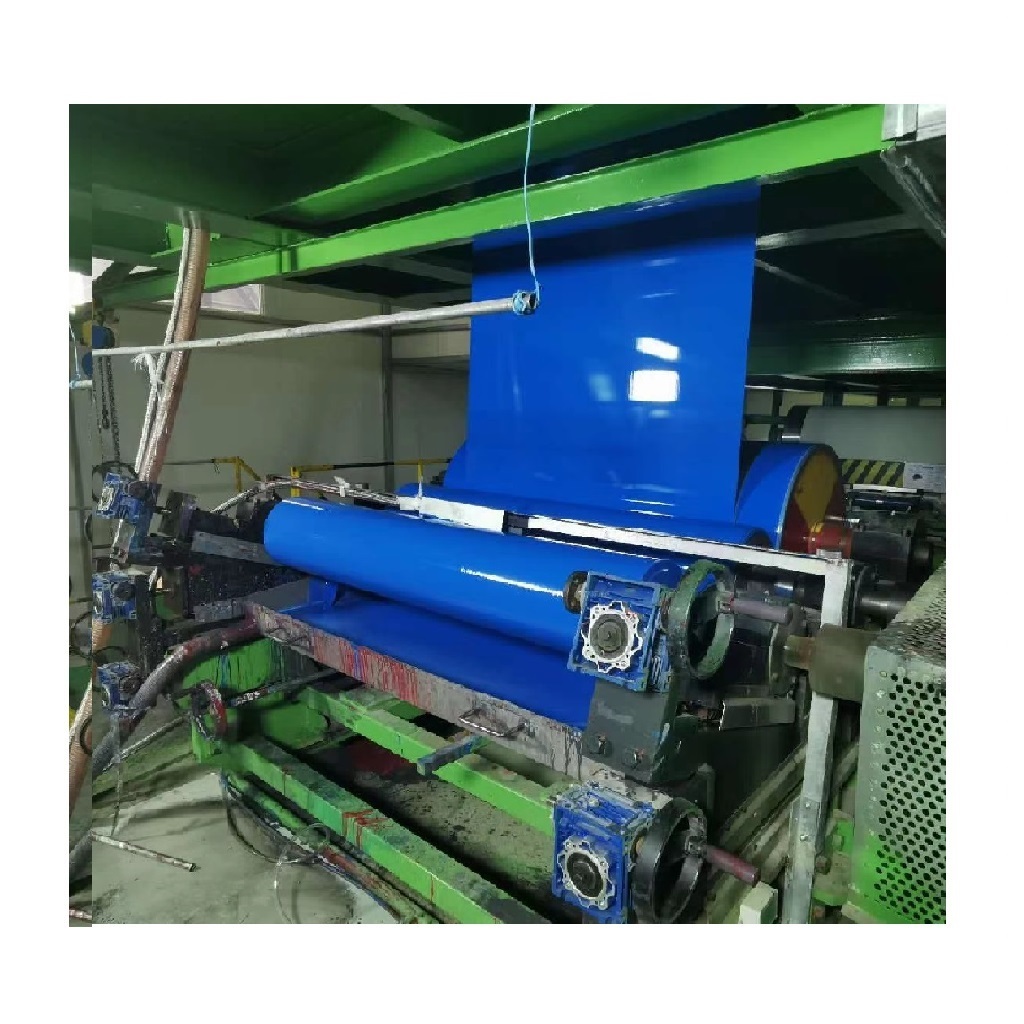

Color Coating Machine

Tension Roller

Processing Procedure:

Pay off reel (uncoiler)---pinch roller---plate shear---sewing machine (stitcher)---inlet accumulator---alkaline washing unit---water washing unit---hot-air blowing device---chemical roller coating machine---chemical-coating drying furnace---prime roller coating machine---prime-coat curing furnace---air cooling---water cooling---drying---top-coat roller coating machine---top-coat curing furnace---air cooling---water cooling---drying---pattern printing unit (optional)---over-coat roller coating machine---over-coat curing furnace---hot film laminating machine (optional)---over coat (laminated film) forced cooling room---drying---cold film laminating machine---outlet accumulator---shear servo tension reel unit---tension reel

Packing & Delivery

1. Export standard wooden cases packed in suitable container.

2. Cooperate with reliable shipping company to ensure the delivery time.

3. Customized packing is allowed.

2. Cooperate with reliable shipping company to ensure the delivery time.

3. Customized packing is allowed.

Hot Searches