- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MST

-

Dimension(L*W*H):

-

2500*650*1700mm

-

Weight:

-

300 KG

-

Product name:

-

5gallon botttled water filling machine

-

Capacity:

-

150 / 300 / 450 / 600 /900 BPH

-

Type:

-

Filling Machine, Filling Machine

-

Filling volume:

-

10L - 20L (5 Gallon )

-

Function:

-

Rinsing filling capping

-

Suitable for:

-

Big bucket water

-

Processing Types:

-

Gravity Filling

-

Filling Liquid:

-

water

-

Operation:

-

Automatic Operation

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Water

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MST

-

Dimension(L*W*H):

-

2500*650*1700mm

-

Weight:

-

300 KG

-

Product name:

-

5gallon botttled water filling machine

-

Capacity:

-

150 / 300 / 450 / 600 /900 BPH

-

Type:

-

Filling Machine, Filling Machine

-

Filling volume:

-

10L - 20L (5 Gallon )

-

Function:

-

Rinsing filling capping

-

Suitable for:

-

Big bucket water

-

Processing Types:

-

Gravity Filling

-

Filling Liquid:

-

water

-

Operation:

-

Automatic Operation

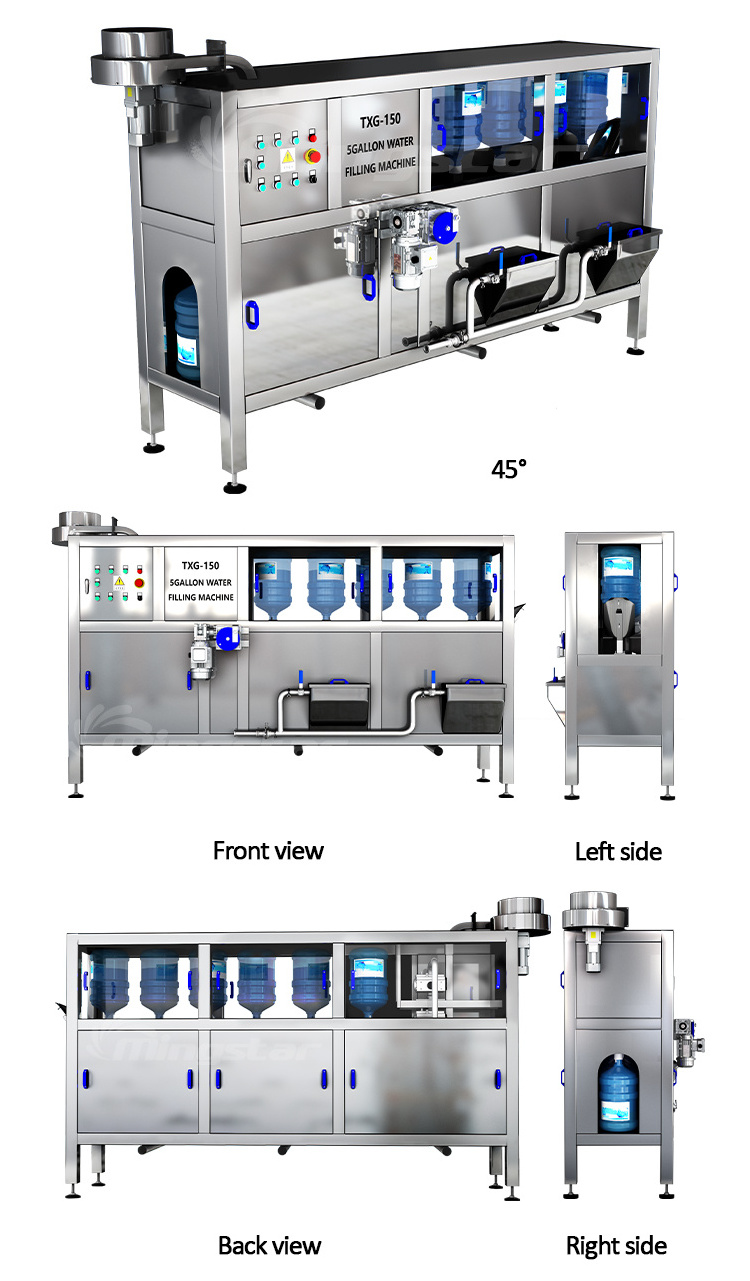

Summary

TXG-150

washing, filling, capping machine is the key equipment for drinking barreled water of 3 gallon and 5 gallon production. It is the ideal equipment for mineral water, purified water production. This equipment is automatic one with three functions in it, they are washing, filling and capping. The capping system is drived by cylinder. There are enough caps for one hour usage in cap bin. Washing pressure is indicated, inner washing pressure is more than 0.28 MPA, washing time is longer than 16 seconds, external washing pressure is more than 0.2 Mpa. The

main electricity parts adopt SIEMENS, Mitsubishi products. Air powered parts adopt AIRTAC products.

Technical Parameters

The device integrates the bottle cap and cleans the inside and outside of the barrel, and has reliable performance, simple operation and convenient maintenance.

All machines could be customized , we could design design and produce machines according to your request.

|

Model:

|

TXG-150B

|

|

Rinsing position number:

|

7

|

|

Rinsing heads:

|

5

|

|

Rinsing conveyor:

|

Motor driven

|

|

Water tanks:

|

Inner AISI304 tanks equipped dosing port

|

|

Filling heads:

|

1

|

|

Filling type:

|

Non-contact filling

|

|

Capping heads:

|

1

|

|

Capping type:

|

Plastic press-cap

|

|

Suitable bottle:

|

PET, PC bottle

|

|

Diameter of bottle:

|

Φ265-Φ273mm

|

|

Height of bottle:

|

400-500mm

|

|

weight:

|

420Kg

|

|

Material:

|

AISI 304 Frame, AISI 304 sheet

|

|

Control system:

|

PLC

|

|

Total power:

|

2470W

|

Please contact us to confirm the product parameter before payment.

Details Images

Related Products

What we offer?

Consultation Service

Filling Machine Choosing

Filling Machine Customization

Filling Line Updating

Turn-Key Solution

Manufacture & Test Service

Filling Machine Stress Testing

Packing & Logistic

Technical Support

SGS Certification

After Sales Service

Installation & Worker Training

Technical Support Online

Annual Diagnosis & Updating

Optional Value-added Service

Agent Recruitment Programme

Client Guarantee Programme

Customer Development Programme

Label Design.

We can provide the label design

according to the bottle size, the

icon style you want.

Bottle Design.

Our designers can design bottle

styles according to your

requirement.

Machine Layout.

We will design andconfirm the

machine layout according to

your factory sketch.

Partner customers

We are a professional manufacturer of beverage machinery in China. With the scientific progressive conception of rapid introduction, we make our machinery cover all over the overseas market.

We have been producing our goods with mature techniques and first-class quality.

With years of export experience along with excellent quality, advanced services and competitive prices, Mingstar has won numerous customers' trust and support.

Packing & Delivery

Packing Details :

Plastic film and wooden case packaging, double protection

Delivery Details :

Delivery within 30 days by sea

Two years warranty after receiving the equipment .

FAQ

Q:HOW TO ENSURE THE QUALITY OF FILLING MACHINE?

※In order to ensure the accuracy of each part, we are equipped with a variety of professional processing

equipment.

※Each component before assembly needs strictly control by inspecting personnel.

※Each assembly is in charged by a master who has working experience for more than 6 years.

※After all the machines are completed, we will connect them together and run the full production line

for at least 12 hours to ensure the stable running in clients' factory.

※We offer whole filling line testing production service in our factory for hours by request.

Q: WHAT WARRANTY OF FILLING MACHINE CAN I GET FROM MINGSTAR?

※Two years warranty after receiving the equipment . Free spare parts and technical supports.

※New client guarantee programme offers longer warranty and customized after service.

※Local after service network is under construction.

※Annual engineer visiting for diagnosis and updating service.

Q: Any other questions?

※Send inquiry to Mingstar.

※Chat now through Alibaba APP.

※Call us or reserve a call.

Hot Searches