- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

55

-

Weight (KG):

-

2200

-

Product name:

-

metal crusher machine

-

Application:

-

Scrap metal recycling

-

Quality:

-

High Level

-

After Warranty Service:

-

Field Maintenance

-

Advantage:

-

Easy Operation High Efficiency

-

Certification:

-

CE ISO TUV

-

Function:

-

Scrap Metal Shredding

-

Feeding size:

-

Customized

-

Output Sizes:

-

≥5mm

-

Processing Material:

-

Scrap steel iron,card body,cans,bicycle body,etc.

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

New Product 2024

-

Brand Name:

-

Aite

-

Power (kW):

-

55

-

Weight (KG):

-

2200

-

Product name:

-

metal crusher machine

-

Application:

-

Scrap metal recycling

-

Quality:

-

High Level

-

After Warranty Service:

-

Field Maintenance

-

Advantage:

-

Easy Operation High Efficiency

-

Certification:

-

CE ISO TUV

-

Function:

-

Scrap Metal Shredding

-

Feeding size:

-

Customized

-

Output Sizes:

-

≥5mm

-

Processing Material:

-

Scrap steel iron,card body,cans,bicycle body,etc.

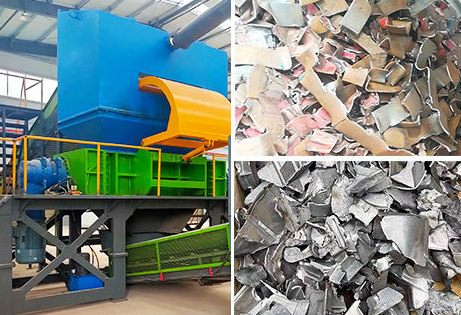

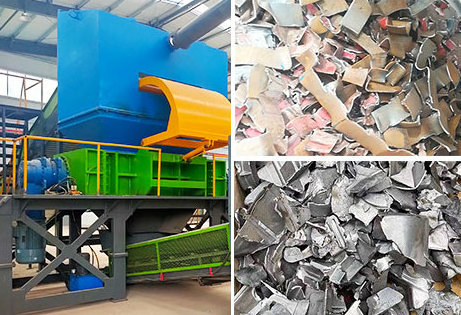

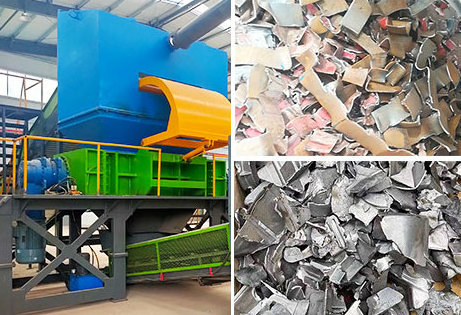

Product Overview

Metal Shredder Machine

The metal shredder is mainly used for crushing scrap metal, increasing its bulk density for transportation and recycling. This equipment is widely used in shredding paint drums, diesel drums, thin iron sheets, car shells, metal briquettes, metal plate scraps, and other scrap metal materials.

We can customize metal crushing and recycling production line for you.

We can customize metal crushing and recycling production line for you.

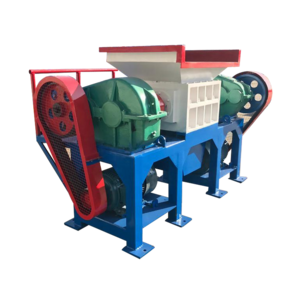

Working Principle Of Crusher

The blade of the metal shredder is made of high-strength alloy steel, which has the characteristics of strong wear resistance and high strength. The differential speed between the shafts has the functions of tearing, squeezing and biting. It is professionally designed for crushing metal. The design has the advantages of uniform discharge, large output and low noise. The electrical part adopts PLC control, with automatic detection of overload protection and other functions.

The blade of the metal shredder is made of high-strength alloy steel, which has the characteristics of strong wear resistance and high strength. The differential speed between the shafts has the functions of tearing, squeezing and biting. It is professionally designed for crushing metal. The design has the advantages of uniform discharge, large output and low noise. The electrical part adopts PLC control, with automatic detection of overload protection and other functions.

Applicable Materials

The output particles after shredding scrap metal can be customized.

Metal Crushing Recycling Plant

We can customize metal crushing and recycling production line for you.

Scrap Steel Crushing Recycling Line

Waste Aluminum Crushing Production Line

Water Radiator Crushing Sorting Line

Knife Details Of The Metal Shredder

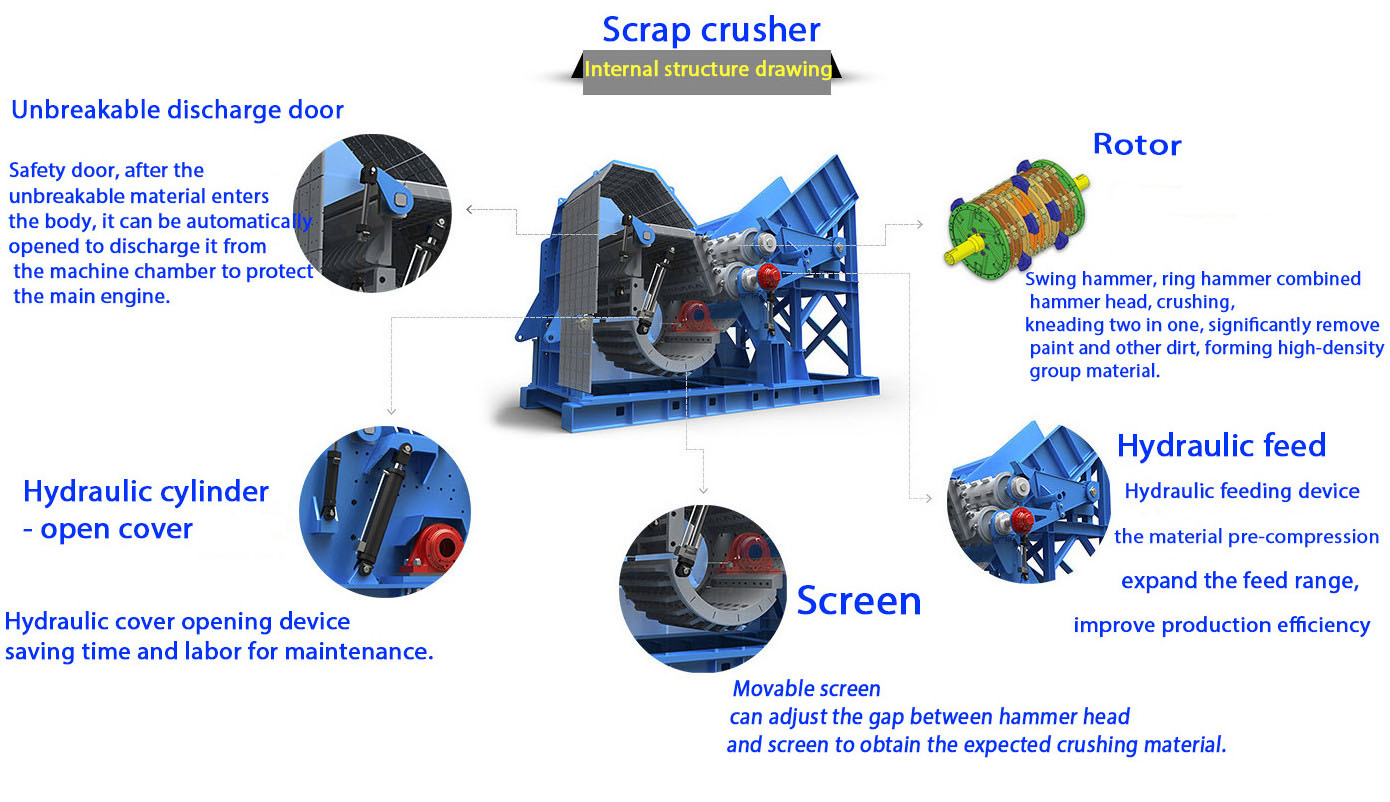

Our Advantage

1. Super high crushing efficiency

Hydraulic feeding, hammer throwing and ring hammer combined crushing hammer head can improve the efficiency of other crusher equipment by 5% - 15%.

2. Perfect finished granules

The unique roller rubbing process can significantly remove the paint and other contaminants, form high-density pellets and improvethe grade of crushing materials.

3. Stable operation capability

When the safety door is set, after the non-breakable material enters the crushing chamber, the operator can open the safety door and discharge it from the body to avoid damaging the crusher.

4. Intelligent Control System

PLC control system and hydraulic power system can save time and labor in intelligent production and realize stable, automatic and safe operation of the whole production line.

Hydraulic feeding, hammer throwing and ring hammer combined crushing hammer head can improve the efficiency of other crusher equipment by 5% - 15%.

2. Perfect finished granules

The unique roller rubbing process can significantly remove the paint and other contaminants, form high-density pellets and improvethe grade of crushing materials.

3. Stable operation capability

When the safety door is set, after the non-breakable material enters the crushing chamber, the operator can open the safety door and discharge it from the body to avoid damaging the crusher.

4. Intelligent Control System

PLC control system and hydraulic power system can save time and labor in intelligent production and realize stable, automatic and safe operation of the whole production line.

PRODUCT SPECIFICATIONS

|

model

|

size(mm)

|

Shredder room(mm)

|

Blads(mm)

|

motor(k)

|

weight(k)

|

|

Aite-600

|

2800×1300×1850

|

600×480

|

200

|

11×2

|

2200

|

|

Aite-800

|

3000×1300×1850

|

800×480

|

200

|

15×2

|

2500

|

|

Aite-1000

|

3300×1900×2200

|

1000×690

|

300

|

22×2

|

5200

|

|

Aite-1200

|

3600×2000×2200

|

1200×690

|

300

|

30×2

|

6400

|

|

Aite-1500

|

4180×2100×2400

|

1500×850

|

550

|

55×2

|

9000

|

|

Aite-1800

|

5800×2400×3300

|

1800×1206

|

550

|

75×2

|

13600

|

|

Aite--2000

|

6400×2700×3500

|

2000×1490

|

600

|

90×2

|

20100

|

|

Aite-2500

|

7500×3200×3800

|

2500×1800

|

600

|

110×2

|

25000

|

Successful Project

Hot Searches