- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FTM

-

Dimension(L*W*H):

-

2650x2460x2800mm

-

Weight:

-

22.4 KG

-

Product name:

-

High performance impact crusher for chemical industry

-

Model:

-

PF-1214

-

Max. feeding size:

-

350mm

-

Usage:

-

Secondary

-

Keyword:

-

impact crushing machine

-

Installation:

-

Engineer Guide

-

Spare parts supply:

-

Lifelong Time

-

Color:

-

customized

-

After sale Service:

-

available

-

Factory visit:

-

Welcomed Warmly

Quick Details

-

Application:

-

secondary crushing

-

Capacity(t/h):

-

1-1000tph

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTM

-

Dimension(L*W*H):

-

2650x2460x2800mm

-

Weight:

-

22.4 KG

-

Product name:

-

High performance impact crusher for chemical industry

-

Model:

-

PF-1214

-

Max. feeding size:

-

350mm

-

Usage:

-

Secondary

-

Keyword:

-

impact crushing machine

-

Installation:

-

Engineer Guide

-

Spare parts supply:

-

Lifelong Time

-

Color:

-

customized

-

After sale Service:

-

available

-

Factory visit:

-

Welcomed Warmly

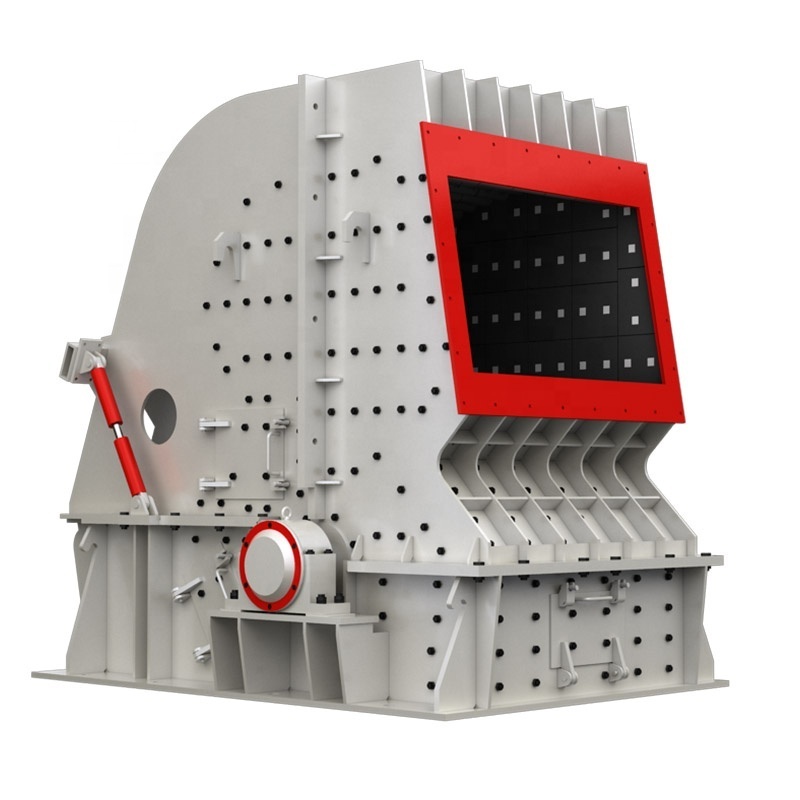

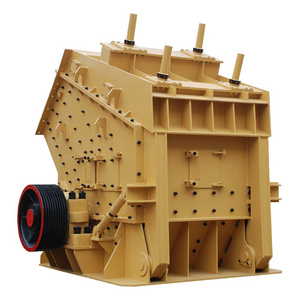

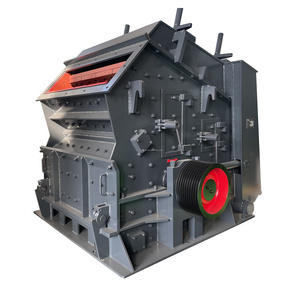

Highcapacityimpactcrusherstonecrushingmachine

From quarries to industrial applications, from mining to recycling, when output and productivity requirements become increasingly stringent, impact crushers are the solution.

Introducing our impact crushers - the perfect equipment for more than 40 years of creating reliable, high-performance crushing solutions. Designed for increased profitability, they combine cutting-edge impact crushing technology with a rugged design to achieve higher crushing rates with fewer crushing stages, allowing you to focus on your operations with confidence.

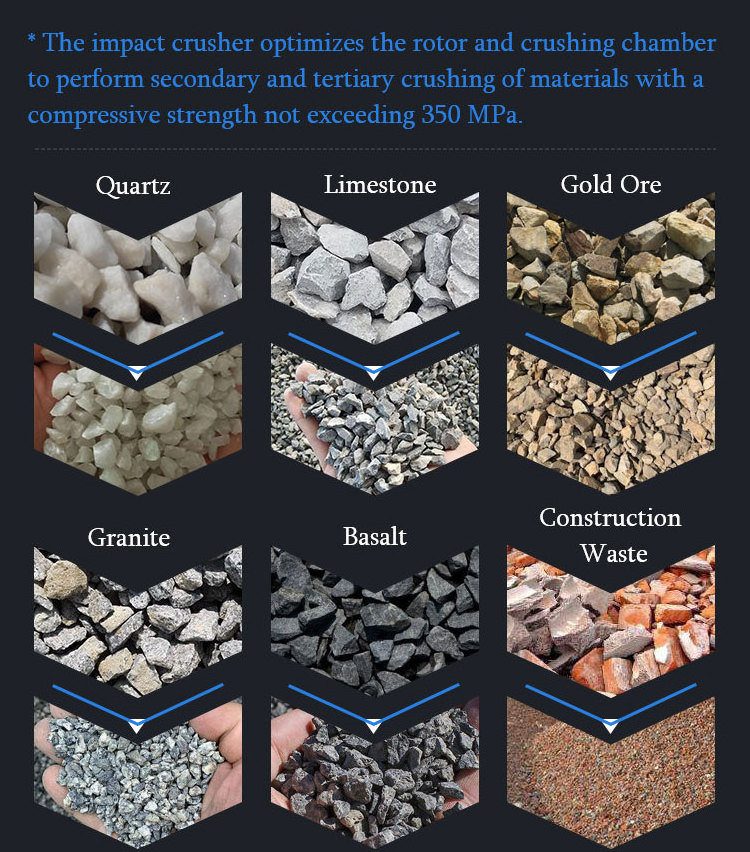

Whether it is the multifunctional PF series, the advanced CI series, or the mobile model, the impact crusher optimizes the rotor and crushing chamber to perform secondary and tertiary crushing of materials with a compressive strength not exceeding 350 MPa.

- Applicable materials: Limestone, granite, basalt, cobblestone, gold ore, chrome ore, iron ore, gypsum, glass, cement, concrete, asphalt, slag, construction waste, etc.

- Feeding material: The feed size does not exceed 800 mm.

- Output: Uniform and cubic shape. And the discharge granularity is adjustable.

- Capacity: 30-2,000 t/h

- Applications: Railways, highways, airports, cement, chemicals, construction, and other industries that require cube-shaped rocks.

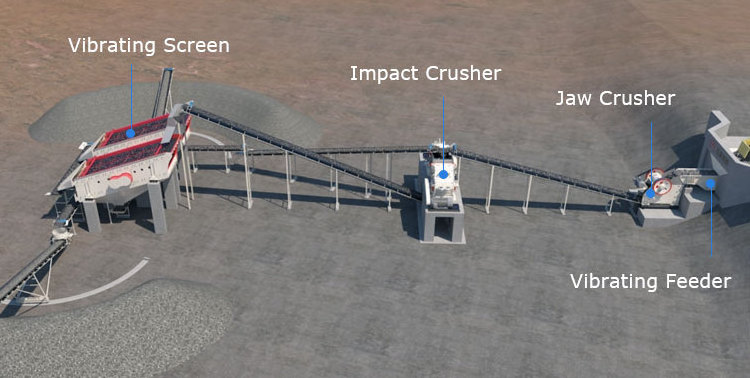

The impact crushers usually form a complete crushing system with the jaw crusher. The system handles various types of mineral, rock and aggregate products. Please refer to the device's parameter sheet or consult us for details.

Impact Crusher Working Principle

Impact crushers use impact energy to crush materials. First, the electric motor drives the rotor to rotate at high speed. When the material enters the crushing cavity from the feed port, it is crushed by the impact of the rotor hammer. The crushed material strikes the impact plate at high speed for secondary crushing. The rebounded material collides with the subsequent material until it is crushed to the required particle size and is discharged from the outlet.

Check out the video on how a impact crusher works

The entire equipment has a simple structure, small size, light weight, and is easy to install, maintain and transport. Its components include blow bar, rotor, main shaft, and impact plate.

The above structural design creates the excellent crushing effect and long service life of the impact crusher:

- Large feed port and high crushing cavity, suitable for large pieces of hard materials with low powder rate.

- The oversized and sturdy heavy-duty rotor is reasonably matched with the cavity type, speed and power, which increases the output and crushing ratio, and meets the application options of coarse crushing, medium crushing, fine crushing and recycling.

- The high crushing ratio can simplify the crushing process, convert three-stage crushing into two-stage or single-stage crushing, and reduce the cost of the mineral processing plant.

- Wear-resistant high-chromium blow hammer, unique blow hammer locking system and high-quality welded structure enhance the crushing performance and life of the equipment.

- Modular design makes most wearing parts interchangeable, reducing the consumption of wearing parts, extending the replacement cycle and saving costs.

- The gap between the impact plate and the plate hammer is easy to adjust. The output size is effectively controlled and the particle shape is in a good cubic shape.

- Hydraulic lid opening and hydraulic adjustment device for the discharge port (with automatic overload protection function) can quickly replace worn parts, control the discharge granularity and gradation, and shorten downtime.

- Energy saving and environmental protection, low maintenance cost, strong profitability of the factory.

| Model | Specifications (mm) | Max.Feeding Size (mm) | Capacity (t/h) | Power (kw) |

| PF-1007 | Φ1000×700 | 300 | 30-70 | 4P 37-45 |

| PF-1010 | Φ1000×1050 | 350 | 50-90 | 4P 45-55 |

| PF-1210 | Φ1250×1050 | 350 | 70-130 | 6P 110 |

| PF-1214 | Φ1250×1400 | 350 | 80-180 | 6P 132 |

| PF-1315 | Φ1320×1500 | 500 | 100-280 | 6P 200 |

| PF-1320 | Φ1300×2000 | 500 | 140-380 | 6P 250 |

| PF-1520 | Φ1500×2000 | 700 | 200-550 | 4P 315-400 |

| PF-1820 | Φ1800×2000 | 800 | 300-800 | 6P 630-710 |

Our impact crushers have been sold to more than 100 countries including Malaysia, Philippines, Indonesia, Sri Lanka, South Africa, Kenya, Egypt, United Arab Emirates, Mexico, Ruiza, and Canada. These stone crushing crushers enjoy a global reputation.

Henan Fote Heavy Machinery Co., Ltd was founded in 1982 in Zhengzhou, Henan, the capital of Chinese machinery manufacturing. The company is large in scale and has four major production bases with a total area of 500,000 square meters, of which standardized heavy industry plants cover an area of 360,000 square meters, providing advanced and reliable infrastructure for production.

Our company focuses on the development and production of mining machinery, including crushers, mills, beneficiation equipment, briquette machines, rotary kilns and other products, which are widely used in mining, chemical industry, construction, coal, ceramics, and other industries. With excellent quality and professional solutions, it has won the trust of customers around the world.

1. We provide customers with a full range of services, including solution design, technical process planning, and the design and manufacturing of standard and non-standard equipment.

2. We dispatch professional technicians to the customer site to assist with shell welding, equipment installation, adjustment, and training of operators.

3. We visit customers regularly to provide lifelong service and technical support.

4. Except for wearing parts, we provide one-year warranty, long-term supply of spare parts, and two-year maintenance of major parts if used correctly.

1. Our equipment holds ISO 9001, CE, and GOST certifications and all equipment undergoes pre-wiring, assembled, and factory tested at our manufacturing facility.

2. We take a test on each machine before delivery.

1. How to get the best price for equipment?

- We are the direct manfacturer, so we can offer you the lowest price than the market price.

- The price of the machine can be given the largest discount based on quantity.

2. Our payment term

- Paypal, T/T, L/C, and Western Union are all available.

- 30% deposit in T/T advance, 70% balance before shipment.

- We take photos of finished products before delivery.

3. Delivery time

- Streamlined production allows for prompt delivery of most products within 6-8 weeks.

- The delivery time will be based on the machine type, selected shipping method, and parts availability.

4. Packaging

- The equipment is wrapped in plastic film before packaging to avoid moisture at sea.

- Bare machines are packed in export containers.

- The motors and small parts are packed in waterproof, sealed, and sturdy wooden cases.

5. Transportation

- Standard container or bulk cargo transportation.

- Sea transportation, air transportation, land transportation, according to customer requirements.

- Complete shipping options and best services at lowest prices are provided: MSC, APL, COSCO, OOCL, CSCL, MSC, MSK, KLINE, etc.

- Seaports in normal use: Qingdao, Tianjin, Shanghai.

- We promise that your goods will be delivered to the destination promptly and safely, and will remind you before the ship arrives.

If you need quality machinery with the latest technology, best prices and fastest delivery, our company is your answer. You are welcome to visit our company and workshop, we sincerely look forward to cooperating with you.