Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

shandong

-

Brand Name:

-

JTL

-

Model Number:

-

JTL-579

-

Product Name:

-

EPS sandwich panel/rock wool sandwich panel

-

Keywords:

-

sandwich panel

-

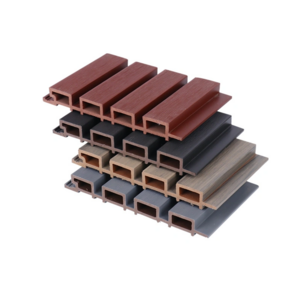

Size:

-

950/1150mm*12m

-

Material:

-

metal rock wool PU

-

MOQ:

-

500sqm

-

Color:

-

Customized Color

-

Design:

-

Mordern/Classic/3d

-

Pattern:

-

DIY Supported

-

Function:

-

roof wall

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design

-

Application:

-

outdoor, heat thermal insulation

-

Design Style:

-

Traditional

-

Place of Origin:

-

shandong

-

Brand Name:

-

JTL

-

Model Number:

-

JTL-579

-

Product Name:

-

EPS sandwich panel/rock wool sandwich panel

-

Keywords:

-

sandwich panel

-

Size:

-

950/1150mm*12m

-

Material:

-

metal rock wool PU

-

MOQ:

-

500sqm

-

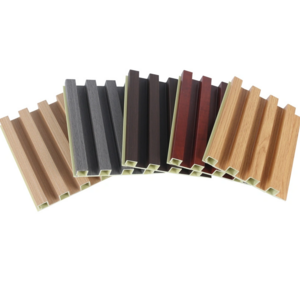

Color:

-

Customized Color

-

Design:

-

Mordern/Classic/3d

-

Pattern:

-

DIY Supported

-

Function:

-

roof wall

Product Description

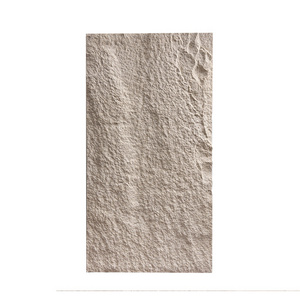

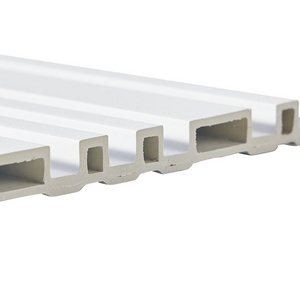

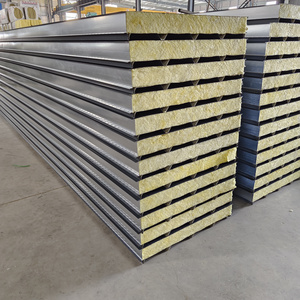

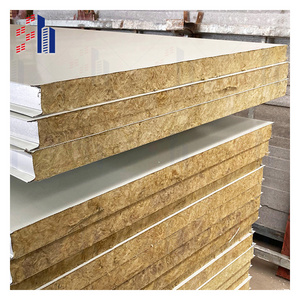

Rock wool sandwich panel is a sandwich panel made of rock wool. Rock wool sandwich panels give full play to the unique properties of rock wool core materials, and have significant effects in fire prevention, thermal insulation, sound absorption and sound insulation. It is suitable for steel structure workshops, roofs and walls of simple mobile houses, ceilings and partitions of air clean rooms, etc.

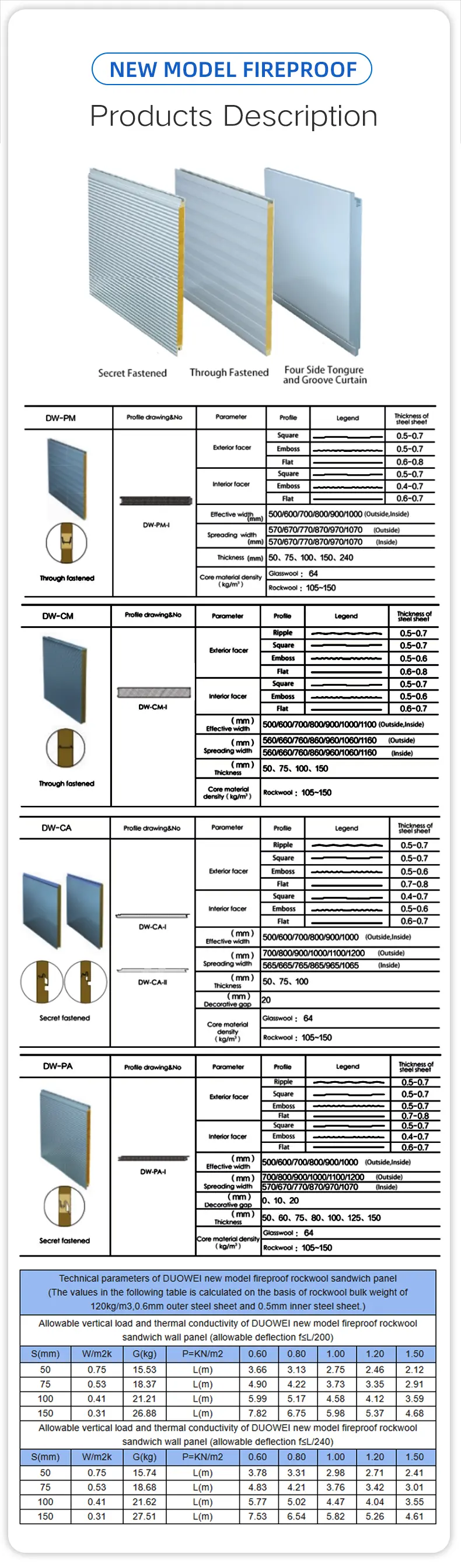

Specification

|

Product Name

|

Color Metal steel Board Insulated XPS EPS PU Rock Wool Glass Wool Wall Roof Sandwich Wall Panel

|

|

|

|||

|

Standard width:

|

1000mm

|

Standard thickness:

|

50mm/75mm/100mm/150mm/200mm

|

|||

|

Combustion performance:

|

Grade A,non-ignitable

|

Insulation performance:

|

Heat transfer coefficient ≤0.04W (M.K)

|

|||

|

Core material density:

|

100-140KG/m³

|

noise reduction performance:

|

Average isolation volume ≥37dB (50mm)

|

|||

|

durability:

|

Unparalleled chemical stability

|

Operating temperature:

|

-268℃-700℃

|

|||

|

*We can select the thickness of internal and external steel plate, coating and steel plate manufacturer according to customer demand.

|

|

|

|

|||

product features

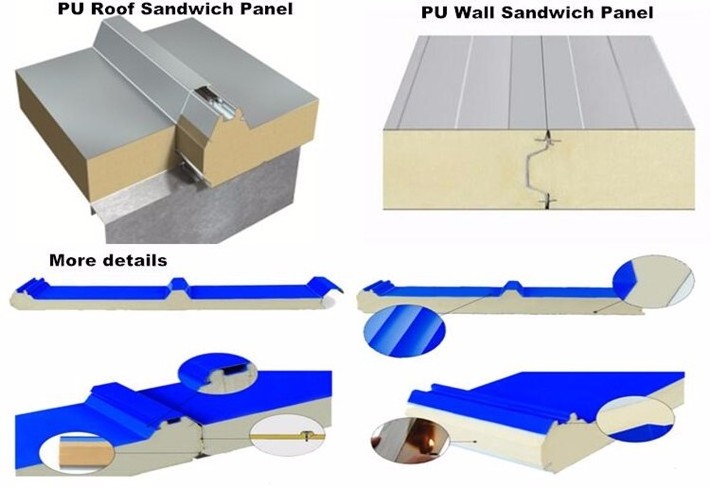

What is the difference between polyurethane edge-sealed rock wool panel and ordinary rock wool panel?

Polyurethane rock wool board, also known as polyurethane material side-sealed rock wool insulation board, flexibly utilizes the thermal insulation properties of polyurethane materials and the fire safety properties of rock wool boards. It is a new sandwich panel integrating thermal insulation and fire safety.

Airtight moisture resistance: PU edge-sealed rock wool thermal insulation panel:Polyurethane material double-sided sealing rock wool sandwich panel adopts the production line processing technology, and then uses the excellent moisture resistance of polyurethane products to get rid of the defect of easy moisture absorption and deliquescence of rock wool panels, and reasonably increases the service life of the product in terms of process performance. General rock wool insulation panel: There are no edges on both sides, and water is very easy to penetrate into the panel to cause deformation of the panel.

Plate-shaped steel bar lap: PU edge-sealed rock wool thermal insulation panel: built-in steel bar lap joint, reasonable increase of service life - general rock wool thermal insulation panel: open nail type installation, exposed external nails are easy to corrode G, environmental protection characteristics. PU-wrapped rock wool insulation panel: Polyurethane material edging reasonably avoids the exposure of the rock wool board—General rock wool insulation board: No urethane material edging causes the rock wool panel to be exposed.

Polyurethane rock wool board, also known as polyurethane material side-sealed rock wool insulation board, flexibly utilizes the thermal insulation properties of polyurethane materials and the fire safety properties of rock wool boards. It is a new sandwich panel integrating thermal insulation and fire safety.

Airtight moisture resistance: PU edge-sealed rock wool thermal insulation panel:Polyurethane material double-sided sealing rock wool sandwich panel adopts the production line processing technology, and then uses the excellent moisture resistance of polyurethane products to get rid of the defect of easy moisture absorption and deliquescence of rock wool panels, and reasonably increases the service life of the product in terms of process performance. General rock wool insulation panel: There are no edges on both sides, and water is very easy to penetrate into the panel to cause deformation of the panel.

Plate-shaped steel bar lap: PU edge-sealed rock wool thermal insulation panel: built-in steel bar lap joint, reasonable increase of service life - general rock wool thermal insulation panel: open nail type installation, exposed external nails are easy to corrode G, environmental protection characteristics. PU-wrapped rock wool insulation panel: Polyurethane material edging reasonably avoids the exposure of the rock wool board—General rock wool insulation board: No urethane material edging causes the rock wool panel to be exposed.

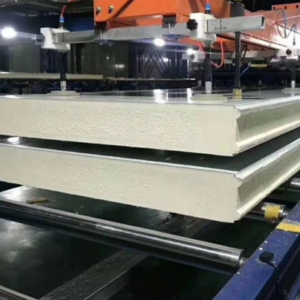

Product Prosess

Recommend Products

Packing & Delivery

40HQ container house loaded

Hot Searches