- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

240 - 730 mm

-

Ejector Stroke(mm):

-

165 mm

-

Ejector Force(kN):

-

70 kN

-

Theoretical Shot Volume(cm³):

-

721 cm³

-

Injection Rate (g/s):

-

270 g/s

-

Injection Weight (g):

-

700 g

-

Screw Speed (rpm):

-

1 - 104 rpm

-

Screw diameter (mm):

-

60 mm

-

Screw L/D Ratio:

-

22.9

-

Weight (KG):

-

85000 kg

-

Place of Origin:

-

Shanghai, China

-

Open Stroke(mm):

-

550 mm

-

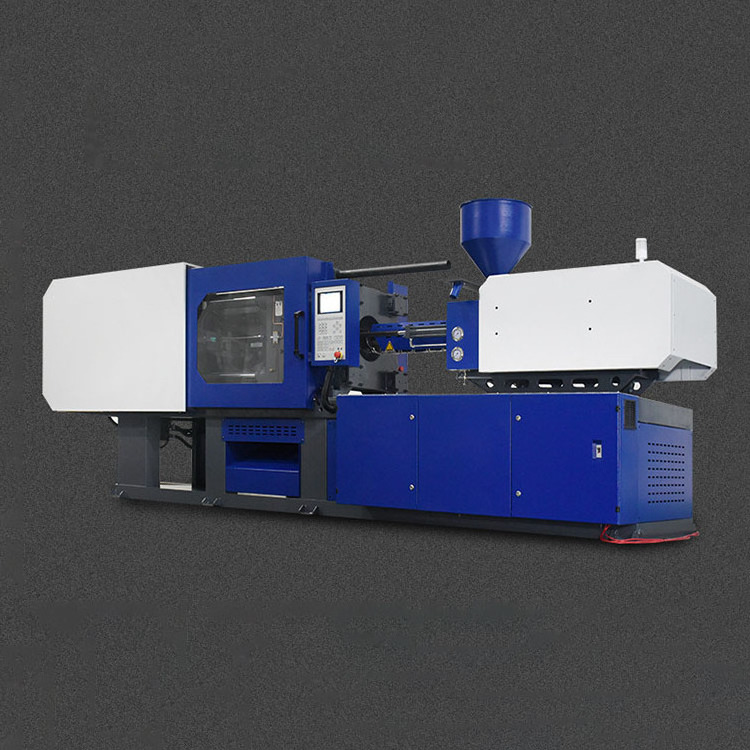

Model Number:

-

injection molding machine

-

Brand Name:

-

Gainjoys

-

Power (kW):

-

22 kW

-

Plastic Type:

-

thermoplastic

-

Automatic:

-

YES

-

Injection Rate:

-

210-293g/s

-

Injection Weight:

-

551-770g

-

Key words:

-

injection molding machine

-

Power(W):

-

22kw

-

Opening Stroke:

-

550

-

Screw type:

-

ABS Etc

-

Clamping Force (kN):

-

2500KN

-

Screw Stroke:

-

210mm

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

580mm

-

Distance between Tie Bars(Height)(mm):

-

580mm

-

Plasticizing Capacity(g/s):

-

270

-

Mold Height(mm):

-

240 - 730 mm

-

Ejector Stroke(mm):

-

165 mm

-

Ejector Force(kN):

-

70 kN

-

Theoretical Shot Volume(cm³):

-

721 cm³

-

Injection Rate (g/s):

-

270 g/s

-

Injection Weight (g):

-

700 g

-

Screw Speed (rpm):

-

1 - 104 rpm

-

Screw diameter (mm):

-

60 mm

-

Screw L/D Ratio:

-

22.9

-

Weight (KG):

-

85000 kg

-

Place of Origin:

-

Shanghai, China

-

Open Stroke(mm):

-

550 mm

-

Model Number:

-

injection molding machine

-

Brand Name:

-

Gainjoys

-

Power (kW):

-

22 kW

-

Plastic Type:

-

thermoplastic

-

Automatic:

-

YES

-

Injection Rate:

-

210-293g/s

-

Injection Weight:

-

551-770g

-

Key words:

-

injection molding machine

-

Power(W):

-

22kw

-

Opening Stroke:

-

550

-

Screw type:

-

ABS Etc

-

Clamping Force (kN):

-

2500KN

-

Screw Stroke:

-

210mm

Product parameters

|

INJECTION UNIT

|

|

|

|

|

|

|||||

|

SCREW DIAMETER

|

mm

|

100

|

110

|

120

|

130

|

|||||

|

SCREW L/D RATIO

|

L/D

|

24.2

|

22

|

20.2

|

18.6

|

|||||

|

SHOT VOLUME(THEORETICAL)

|

cm3

|

4238

|

5129

|

6103

|

7163

|

|||||

|

INJECTION PRESSURE

|

Mpa

|

210.5

|

174

|

146.2

|

124.6

|

|||||

|

SCREW SPEED

|

rpm

|

96

|

|

|

|

|||||

|

SHOT WEIGHT(THEORETICAL)(PS)

|

g

|

3856

|

4667

|

4667

|

6518

|

|||||

|

SHOT WEIGHT(THEORETICAL)(PS)

|

oz

|

136.052

|

164.624

|

195.947

|

229.951

|

|||||

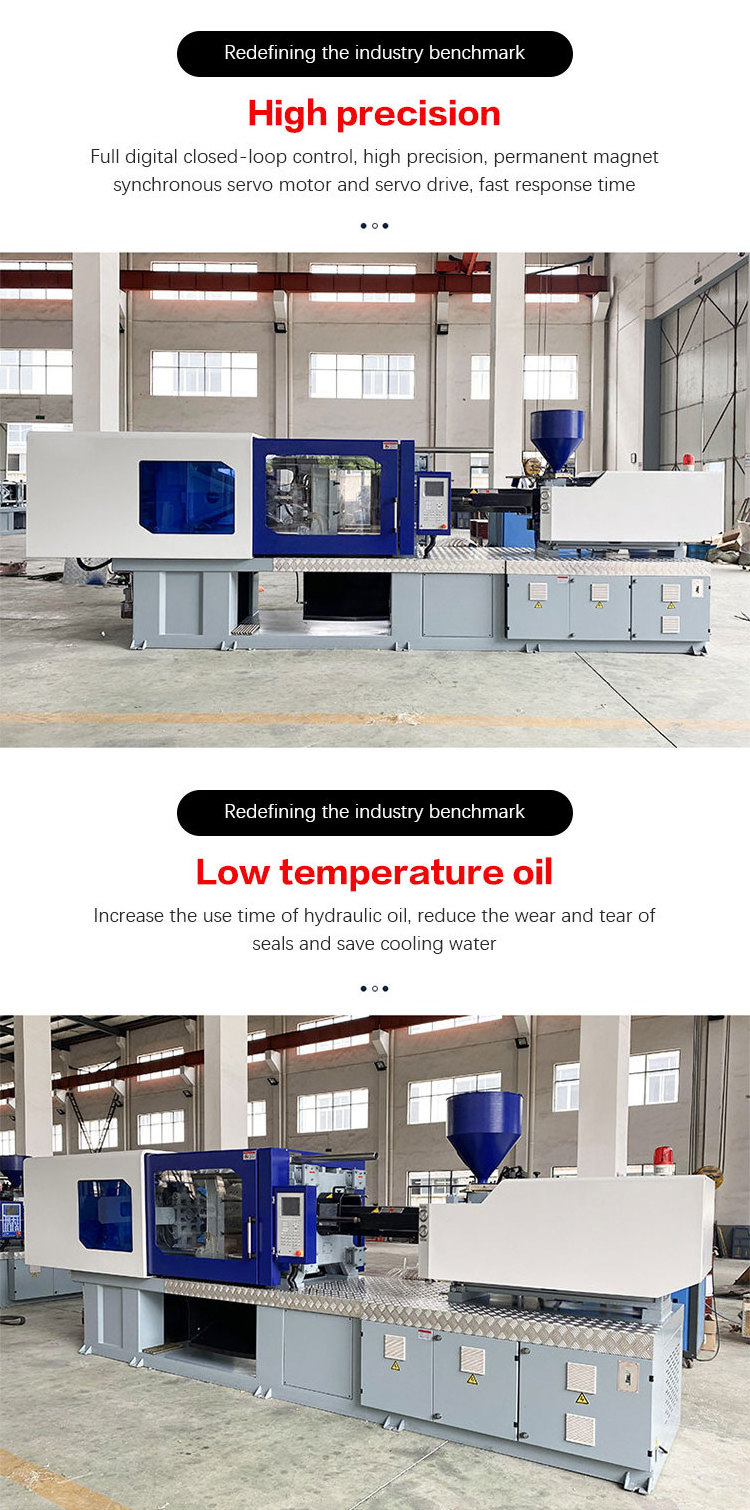

Product display

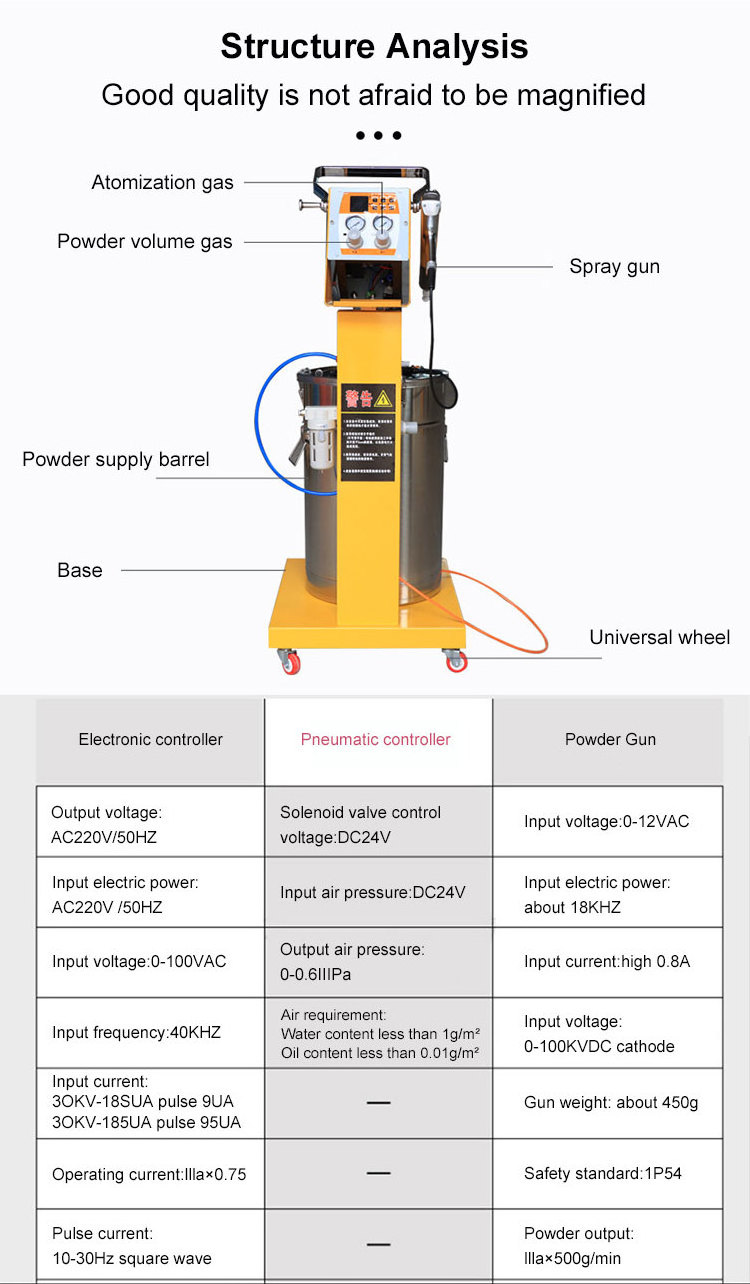

Introduction

Electrostatic Powder Coating Machine is a dry finishing process, using finely ground particles of pigment and resin that are generally electrostatically charged and sprayed onto electrically grounded parts. The charged powder particles adhere to the parts and are held there until melted and fused into a smooth coating in a curing oven. Before coating, the parts to be coated are first pretreated similarly to conventional liquid coated parts. The pretreatment process is normally conducted in series with the coating and curing operatios.

Features

A classic model with a simple design and easy operation, it is ideal for first-time powder sprayers. Easy maintenance due to its simple design. It is good at spraying simple items, capable of spraying certain high volume powder coating jobs, stainless steel powder cans.

Electrostatic spray machine works

Electrostatic powder coating equipment (electrostatic spray machine) the powder coating to the surface of the work, under the action of electrostatic powder evenly adsorbed on the surface of the workpiece to form a powder coating, powder coating baked at high temperatures leveling solidified into varying results (the effect of different types of powder coatings) final coating. This product is widely used in the home appliances, hardware, security door (window), fins, architectural, auto parts, sports equipment, medical equipment, aluminum and other industries.

Operating Instruction

Connect all the connecting lines and air tubes. Turn on switch of power supply (lighting indicator is on).

Press the switch of spray gun to adjust voltage required (set by individual, voltage recommended is 60KV-80KV). Powder is placed into powder feeding barrel. Press the switch of spray gun and adjust to high-voltage. Start work if the powder is sprayed.

Hot Searches