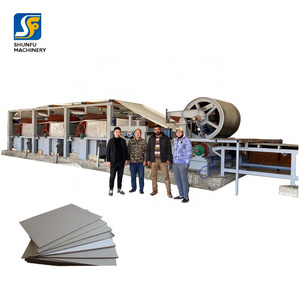

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Power:

-

155KW

-

Dimension(L*W*H):

-

25000m*25000mm*6000mm;

-

Weight:

-

18T

-

Name:

-

pulp tableware plate food packages machine line

-

Raw material:

-

pulp board/reed pulp/wood pulp etc

-

Material consumption:

-

85kg/h

-

Water consumption:

-

260kg/h

-

Robot arm:

-

6-axis robot/4-axis robot

-

Machine type:

-

Automatic Paper Food Container Machine

-

Recycle pump:

-

ISW model horizontal centrifugal pump

-

Forming machine:

-

Forming Unit/Drying &Hot-press unit/Edge Cutting Unit

-

Pneumatic angle seat valve:

-

DN80*1set/DN40*4sets/DN25*6sets/DN15*4set

Quick Details

-

Production Capacity:

-

150 pcs/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HONGRUN

-

Voltage:

-

380V 50HZ

-

Power:

-

155KW

-

Dimension(L*W*H):

-

25000m*25000mm*6000mm;

-

Weight:

-

18T

-

Name:

-

pulp tableware plate food packages machine line

-

Raw material:

-

pulp board/reed pulp/wood pulp etc

-

Material consumption:

-

85kg/h

-

Water consumption:

-

260kg/h

-

Robot arm:

-

6-axis robot/4-axis robot

-

Machine type:

-

Automatic Paper Food Container Machine

-

Recycle pump:

-

ISW model horizontal centrifugal pump

-

Forming machine:

-

Forming Unit/Drying &Hot-press unit/Edge Cutting Unit

-

Pneumatic angle seat valve:

-

DN80*1set/DN40*4sets/DN25*6sets/DN15*4set

• Fully automatic design, integrating the four processes of forming, drying, shaping and edge cuttingMain features: environmental protection, fully automactic with robot arms which can save labors and save cost. with high efficiency. You investiment will be back within 20 working days.

ELECTRIC SYSTEM Electric cabinet

• Totally three electric cabinets, separately control pulping system, forming system, and drying& collection system;

• Including frequency converter, temperature controller, control button, contactor and relay etc. electrical components. Operation unit

• Including one operation box which fixed in forming machine chassis, control the whole system by knobs

and buttons by PLC program. • Including air switch control button, contactor and relay etc. electrical components.

• If customer have customized requirement, this operation box can also use touch screen technology.