- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2.1*2.3*1.9m

-

Voltage:

-

380V,50HZ

-

Power:

-

7.5KW

-

Weight (KG):

-

4000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product name:

-

biochar making machine

-

carbonize time:

-

8-10hours

-

cooling time:

-

5-8hours

-

raw materials:

-

bamboo,briquette,coconut shell,wood waste

-

color:

-

as your request

-

capacity:

-

2-10t

-

carbonization rate:

-

40%

-

advantage:

-

smokeless , little pollution ,energy-saving

-

Weight:

-

4t

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HengYuan Brand

-

Effective Volume:

-

8CBM

-

Dimension(L*W*H):

-

2.1*2.3*1.9m

-

Voltage:

-

380V,50HZ

-

Power:

-

7.5KW

-

Weight (KG):

-

4000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product name:

-

biochar making machine

-

carbonize time:

-

8-10hours

-

cooling time:

-

5-8hours

-

raw materials:

-

bamboo,briquette,coconut shell,wood waste

-

color:

-

as your request

-

capacity:

-

2-10t

-

carbonization rate:

-

40%

-

advantage:

-

smokeless , little pollution ,energy-saving

-

Weight:

-

4t

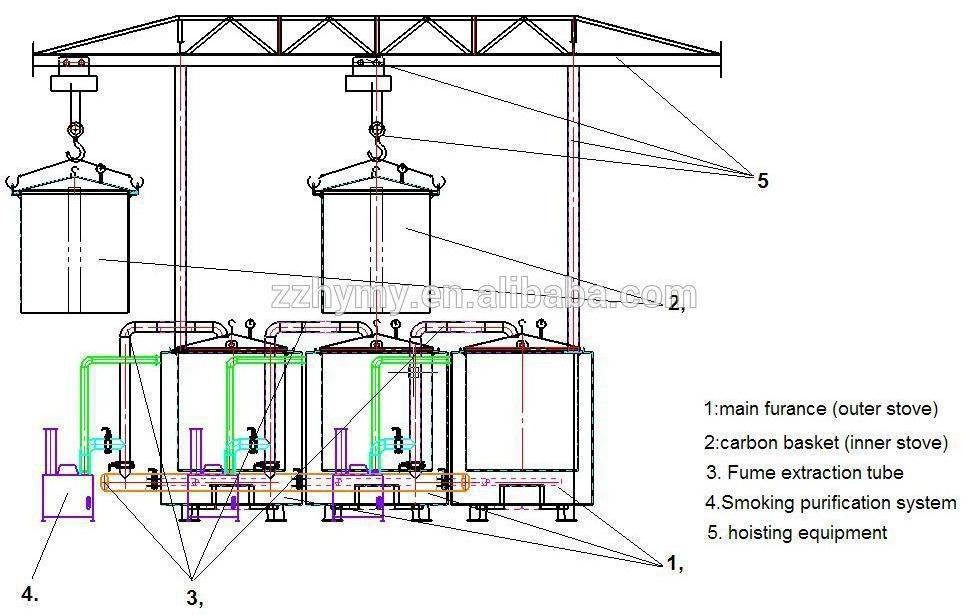

12years manufacturing experience biochar kiln/biochar making machine

Carbonization furnace is used firing bamboo or wooden into charcoal. It is a hot type of gas flow

carbonization stove. It's easy to operate that several stoves can be cared by one person.

|

Briquette carbonization furnace |

|

|

|

|

Capacity |

2-3 ton charcoal per day per set |

|

|

|

Main Structure |

One main furnace with three inner baskets . Main furnace: It includes heating room, furnace body and heat-keeping layer. Carbon basket: The raw materials are the resistance thermal steel plant and sealing cover. Fume extraction tube:During the process of carbonizing, there will be some smoke which can be burning. The smoke can return to the furnace through tube air-blast carbonization. |

|

|

|

No Smoke |

The furnace has tubes to deal with the smoke and tools to collect wood tar oil. |

|

|

|

Operating Principle |

We put one basket with raw materials into the main furnace with the help of the hoisting tools or crane . After 8-10 hours carbonization,we take the basket out and let it cool by nature. At te same time,put another basket into the furnace and repeat the carbonization |

|

|

Picture of internal structure about carbonization furnace

Three sets furnace together

Q:what's the raw materials can be carbonized?

A:such as wood logs,bamboo, wood briquettes,coconut shell, biomass waste,cashew shell, macad amia shell and so on

Q:what's the main structure about carbonization furnace?

A:

Main structure: One set furnace includes one main

furnace and three inner baskets, and necessary hoisting tool or cranes.

Inner stove: the around steel thickness is:6mm, the bottom steel is boiler steel:8mm

Three inner baskets diameter are 1460mm, 1430mm, and 1400mm, height is 1.52m, so the inner

stove volume is 2.54 CBM,2.43CBM and 2.34CBM

Q: Main advantages of charcoal making machine

1 Easy operate and maintain, higher safety, energy saving

2 High carbonization rate ,no smoking, little pollution, high efficiency

3 Newly developed carbonization stove, which can dry the materials with the superfluous energy

produced in the process of carbonization.6-8 hours per stove and can work continuously

4 The tube of fume extraction will recycle the gas flow which come from the inner stove during the

carbonizing process for continue warming the stove, and it will save 70% energy consumption and

ecycle 95% smoking

The whole line of the charcoal

Final product

Our Client

wooden case