- Product Details

- {{item.text}}

Quick Details

-

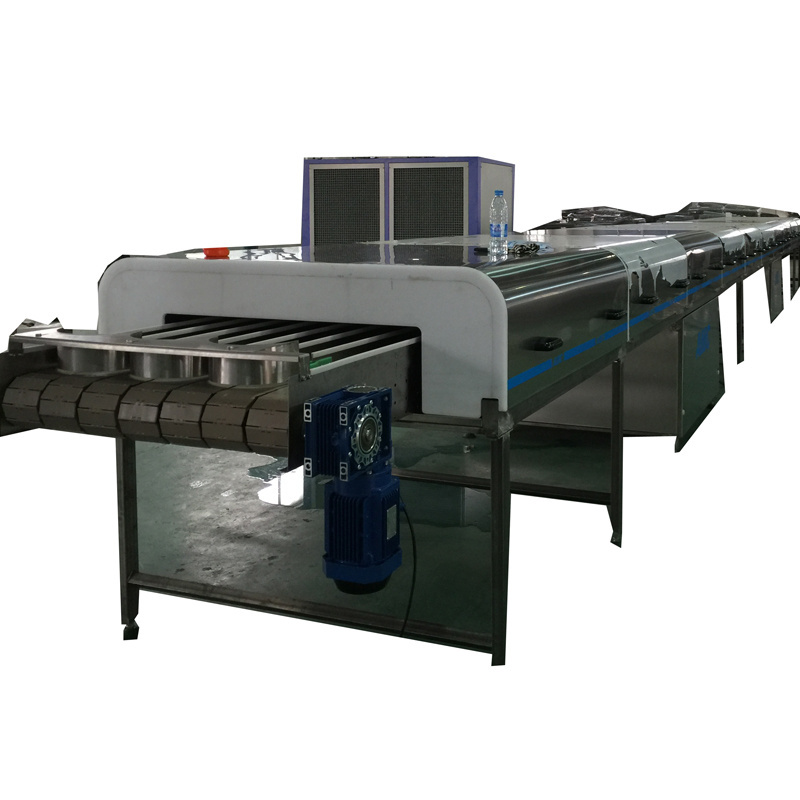

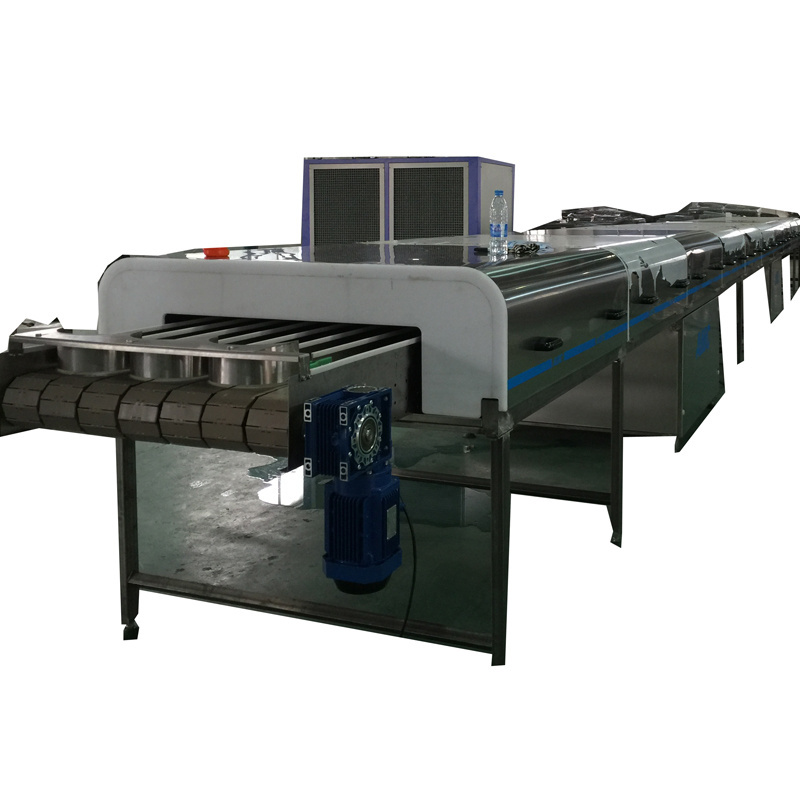

Voltage:

-

220V/380V/420V

-

Power:

-

25KW~65KW, 11KW

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

16*1.75*1.08M

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material of Frame:

-

Stainless Steel 304/316

-

Material of Belt:

-

Slat bel conveyor for food grade

-

Compressor:

-

Bitzer/ Copeland

-

Speed:

-

Adjustable

-

Motor:

-

SEW or Chinese brand

-

Pneumatic:

-

SMC or Chinese brand

-

Cover:

-

Each side can be opened

-

Package:

-

wooden case for jelly cooling tunnel

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AMC-jelly cooling tunnel

-

Voltage:

-

220V/380V/420V

-

Power:

-

25KW~65KW, 11KW

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

16*1.75*1.08M

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material of Frame:

-

Stainless Steel 304/316

-

Material of Belt:

-

Slat bel conveyor for food grade

-

Compressor:

-

Bitzer/ Copeland

-

Speed:

-

Adjustable

-

Motor:

-

SEW or Chinese brand

-

Pneumatic:

-

SMC or Chinese brand

-

Cover:

-

Each side can be opened

-

Package:

-

wooden case for jelly cooling tunnel

|

Type |

Air-cooled / Water-cooled |

|

Weight |

150Kg/Hr |

|

Capacity |

100-1500Kg/Hr |

|

Speed |

Adjustable 1~15 M/min |

|

Voltage |

220V/380V |

|

Power |

10-45KW |

|

Tunnel Temp |

>3℃ |

|

Material of Frame |

Stainless Steel for spagetti pasta |

|

Material of Belt |

PU Belt ,and snack conveyor (Food industry and chemical ) |

|

Application |

Food/chemical Industrial Cooling |

|

Drive Motor |

SEW / CPG 1.1~5.5KW |

|

Compressor |

BITZER / SHUANGLING 5~25 Hp |

|

Condenser |

BITZER / SHUANGLING |

|

Warranty |

1 Year for spagetti pasta

|

|

Package |

Wooden Case for spagetti pasta |

|

Holding Time |

1~60 min for spagetti pasta |

|

Control Models |

PLC & Touch Pannel |

|

Working Temp |

-10~10 ℃ |

|

Common Size |

1150/1450/1750mm |

a. Production capacity: 100~10000kg/h

b. Cooling temp.: -10~10 degree

c. Hilding time: 1~60 min

d. Control models: PLC & Touch pannel

a. Modular solutions combining a range of size, features and cooling elements to suit any application from fragile filled chocolates and cream goods to bars and coated biscuit

b. Radiation, conduction, and conduction cooling

c. Precision temperature contrl

d. Energy efficiency and environmental safety

e. Attractive design with easy cleaning and maintenance

f. Airflow, insulation and hood design for temperature consistency across the entire band width

a. Adjustable infeed tanle

b. FDA-approved band

c. Automatic centering

d. Cooling section

e. Cooling unit

f. Cover

g. Drive unit

h. Base

1. Moulds cycle moving in the cubical space, auto in & out, no joint chains, so its very easy to change the products.

2. Small area covered, which saves the factory space.

3. Good cooling performance, small space of moulds moving, high cooling efficiency to the products.

4Intellectual controlling, which can match the depositor and control the temperature automatically.

Remark:

1 . Delivery Time:

Within 60 Days upon the receipt of the deposit.

2. Terms of payment:

50% T/T in advance, the balance shall be paid before the shipment. The above price is based

on current exchange rate, if the exchange rate changed 2%, we cannot keep the price.

3. Testing & Training (If you need) :

The plant layout design, assembling, installation and debugging, start-up and local team training will be Free at no cost. But the buyer should be responsible for the roundtrip

air tickets, local transportation, board & lodging, and USD $ 45/day/person for the pocket money

to our technicians.

1.provide you OEM/ OEM service,and technology supporting

2.after sales service

3.any feedback received will reply you in 24hrs.