- Product Details

- {{item.text}}

Quick Details

-

Power:

-

3Kw

-

Dimension(L*W*H):

-

1100x500x1000mm

-

After-sales Service Provided:

-

Video technical support, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Rotating Speed:

-

: 0~1800RPM

-

Working Width:

-

350mm

-

Type:

-

Walking behind

-

Vacuum motor:

-

0.75kw

-

Efficient:

-

20-30/h

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Henan

-

Brand Name:

-

YUGONG

-

Voltage:

-

380/220V, 220V/240V 380V/480V

-

Power:

-

3Kw

-

Dimension(L*W*H):

-

1100x500x1000mm

-

After-sales Service Provided:

-

Video technical support, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Rotating Speed:

-

: 0~1800RPM

-

Working Width:

-

350mm

-

Type:

-

Walking behind

-

Vacuum motor:

-

0.75kw

-

Efficient:

-

20-30/h

-

Certification:

-

CE

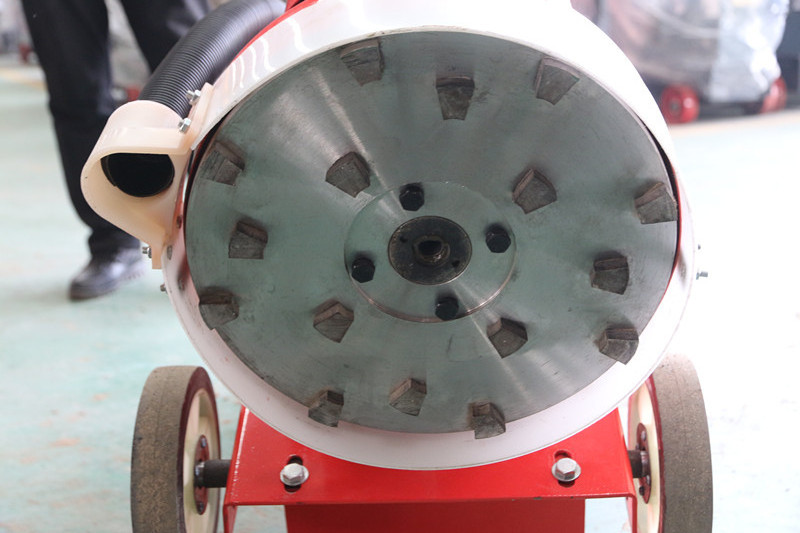

Concrete flooor grinder is mainly used in big or scope ground grinding processing, it can used for concrete surface layer , old epoxy floor, curing agent, epoxy floor paint burnish, marble floor and etc.

It can effectively polish the concrete surface and the epoxy mortar layer and the old epoxy floor, remove the floor surface paint, polyurethane, epoxy resin, remove the surface coating adhesive, cement floor, terrazzo ground to fight hair, epoxy intermediate Layer of polishing, leveling, polishing, etc., is to do the ideal ground handling equipment.

|

Model |

YG350 |

|

Power+ Vacuum cleaner power |

3+0.75 kw |

|

Voltage |

380v/220v |

|

Grinding head quantity |

3 x4 pcs |

|

Work width |

380 mm |

|

Work efficiency |

20~30m2/h |

|

Overall dimension |

1100x500x950mm |

1. Comes with a vacuum cleaner, dust-free construction,

2. With a vacuum cleaner power cord socket, vacuum cleaner power cord can be directly connected and grinder, to avoid work, you need two power cord trouble.

3. With light, flexible, high efficiency and so on.

4. A multi-purpose machine, it can also be equipped with special grinding disc renovation and polishing the ground.

Apply Filed

1. Grinding of standard concrete foundation.

2. Grinding of hard concrete foundation.

3. Grinding of Epoxy resin coating.

4. Removal of old coating.

5. Concrete surface grinding wool processing.

6. Concrete concave convex and fragile layer smooth processing.