- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Baijiarun

-

Voltage:

-

380V 50Hz 3-phase (industrial default)

-

Dimension(L*W*H):

-

Accroding to different type and model

-

Power (kW):

-

7.5 kW

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Mixing Tank

-

Function:

-

Mixing Liquid Materials

-

Keyword:

-

Mixing Machine Powder

-

Name:

-

Powder Mixing Tank

-

Stirrer type:

-

Tank Mixer

-

Capacity:

-

Customers' Request

-

Usage:

-

Cosmetic Industry

-

Type:

-

Making Machine Homogenizer

-

Color:

-

Clients Request

Quick Details

-

Barrel Volume (L):

-

1000

-

Max. Loading Volume (L):

-

890 L

-

Weight (KG):

-

300 KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Baijiarun

-

Voltage:

-

380V 50Hz 3-phase (industrial default)

-

Dimension(L*W*H):

-

Accroding to different type and model

-

Power (kW):

-

7.5 kW

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Mixing Tank

-

Function:

-

Mixing Liquid Materials

-

Keyword:

-

Mixing Machine Powder

-

Name:

-

Powder Mixing Tank

-

Stirrer type:

-

Tank Mixer

-

Capacity:

-

Customers' Request

-

Usage:

-

Cosmetic Industry

-

Type:

-

Making Machine Homogenizer

-

Color:

-

Clients Request

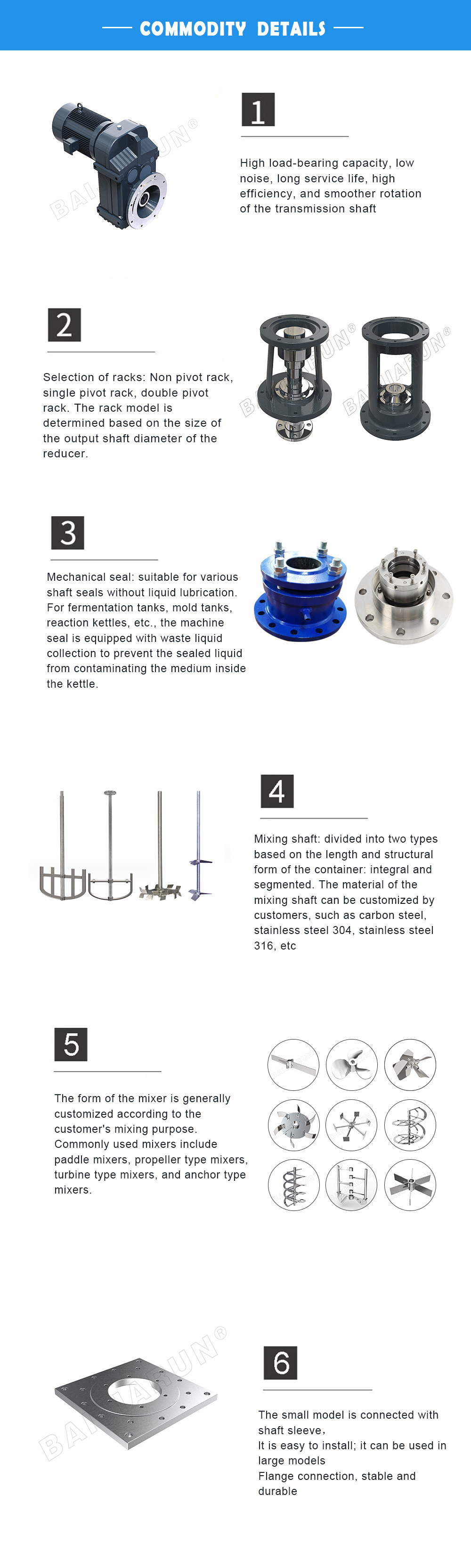

Types of Agitator

Products Description

Delivery time is guaranteed

Various mixing types

Wide range of application

Energy-saving and efficient

Our Advantages

Mixing Flow Field Diagram

|

Size

|

d/D=0.8~0.98

|

|

Operating Condition

|

v<2

|

|

Viscosity Range

|

less than 100Pa.s

|

|

Flow Condition

|

The general material spirals up along the wall of the container, and then converges to the central cavity to form an upper and

lower convective cycle, and has a strong anti-adhesion effect, suitable for mixing, heat transfer, reaction and dissolution operations of high viscosity or powdery materials. |

|

Remark

|

The type and number of spiral belts should be determined according to the geometry of the container and the height of the leaf layer.

|

|

|

|

Certifications

Hot Searches