- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

20KG

Quick Details

-

Voltage:

-

110-240V

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

61*42*25cm

-

Weight:

-

20KG

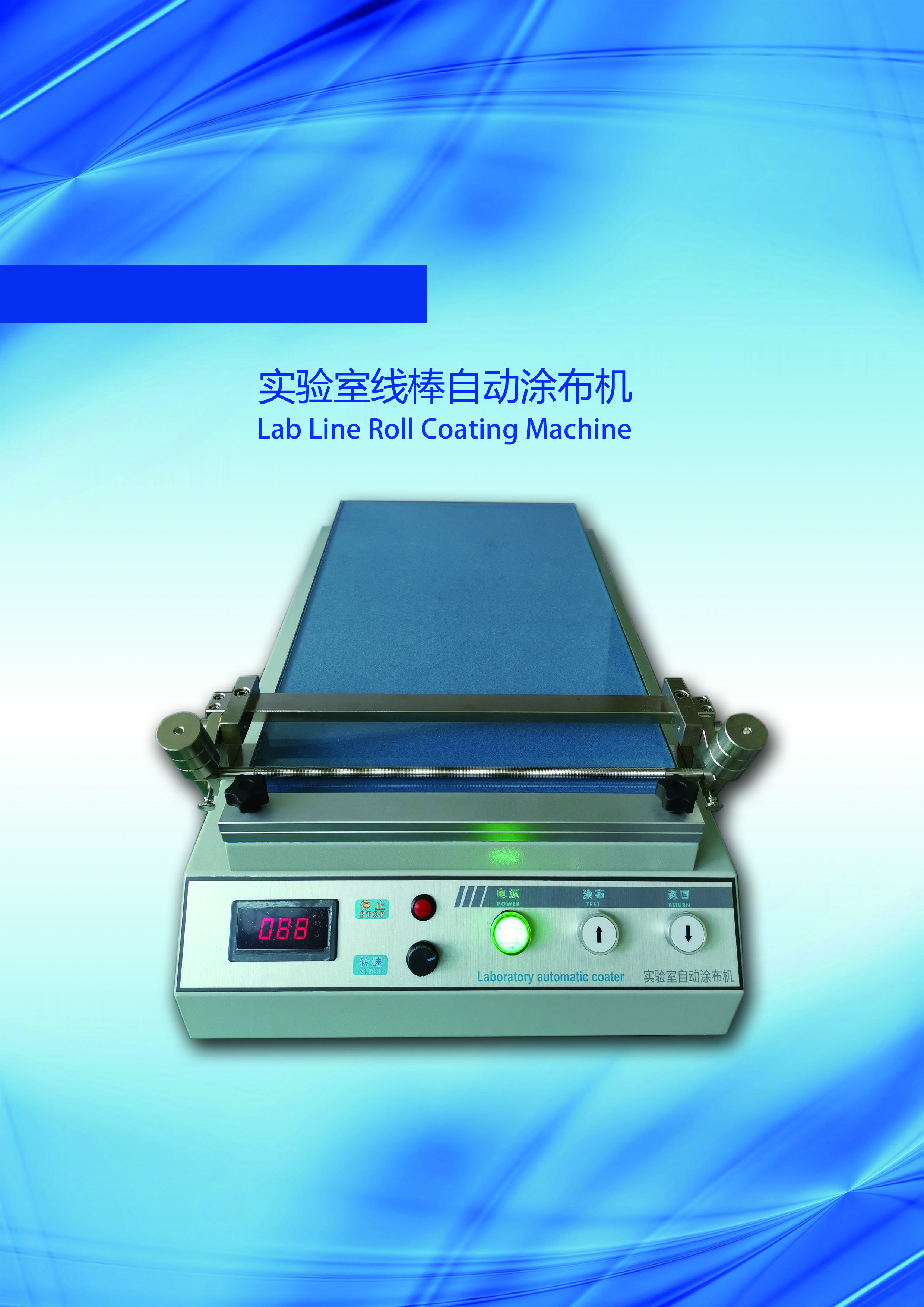

Overview and Features

Laboratory coating machine is an emerging experimental instrument developed in recent years. It is an organic combination of electrical control and mechanical control. It can save a lot of raw materials, improve production technology and improve efficiency in the field of coating experiment. The key is to greatly improve the reproducibility and stability of the coating on the basis of the experiment.

The advantages for the laboratory coating machine :

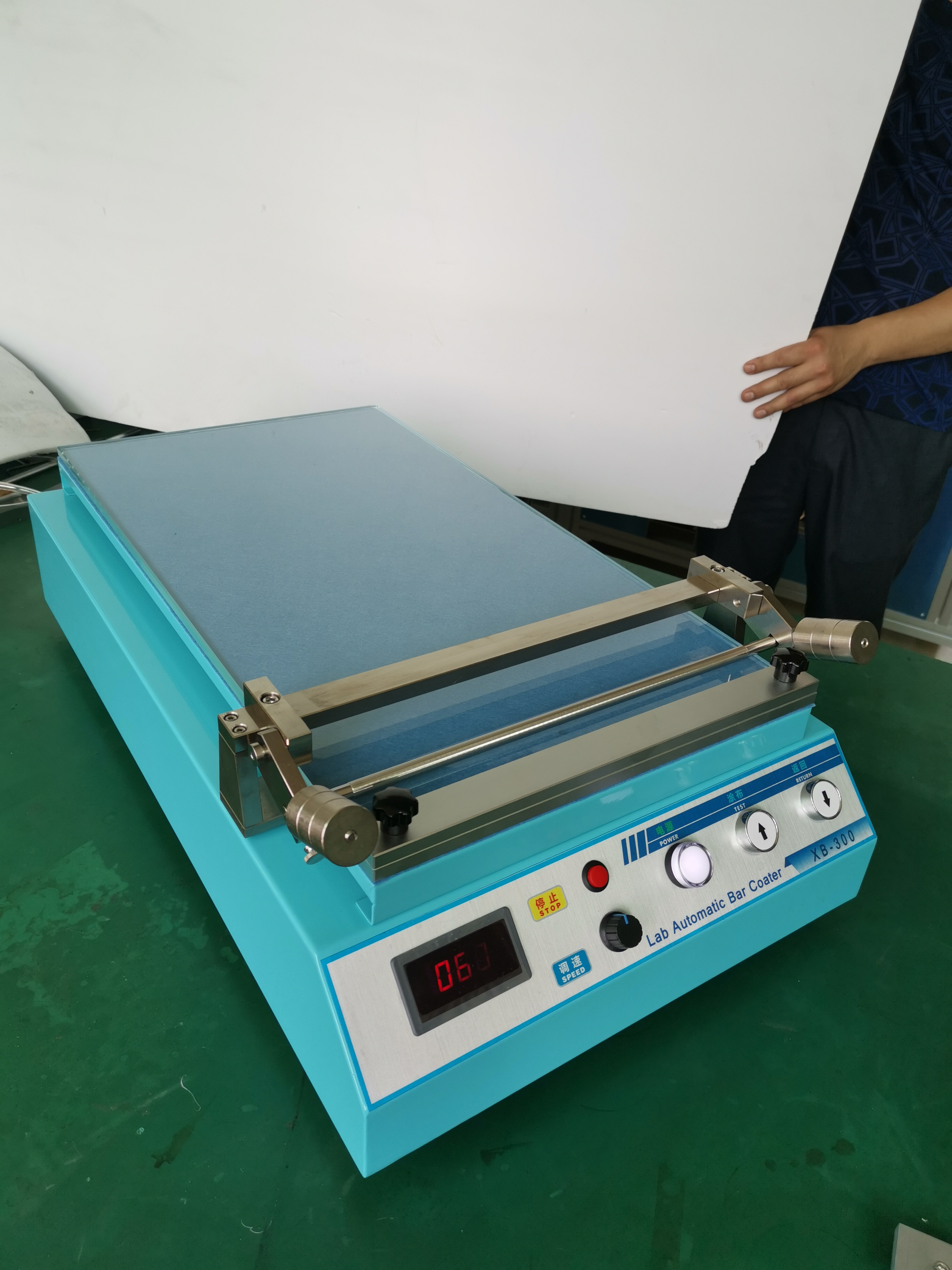

1. Wide application : It can carry out uniform coating experiment on various flat materials such as paper, plastic, metal, PVC, PET, cloth, aluminum alloy plate and so on. Repeatedly and continuously apply smooth and flat test samples without defects

2. Good performance : It is convenient for experimenters to accurately coat different substrates, reducing and eliminating errors caused by human factors such as different coating speeds and different pressures.

3. Repeatability : The coating operation can be repeated at will, without affecting the coating quality; repeated and continuous coating of smooth, flat and flawless test experimental samples.

its using imported matsushita servo motor, through the control of speed and stable pressure to ensure coating effect, ensure coating uniformity and stability, many multinational enterprises research and development institutions, many famous universities at home and abroad.

Product parameters:

|

Coating base size |

320mm× 400mm |

|

Effective coating area |

L300mm*W390mm |

|

Coating speed |

0 ~ 10m/minute adjustable |

|

Coating thickness |

0.005-0.2mm (can be adjusted by different wire bar with different coating thickness) |

|

Wire bar |

One wire bar is include (selected by customer) We also can provide wire bars that with 5um, 10um, 15um, 20um, 25um, 30um....~200um coating thickness at extra cost |

|

Wire bar diameter |

10mm |

|

Power |

48W |

|

Power supply |

110V/220V 50Hz |

|

Package Dimensions |

780mm × 490mm × 290mm (length × width × height) |

|

Weight |

about 30Kg |

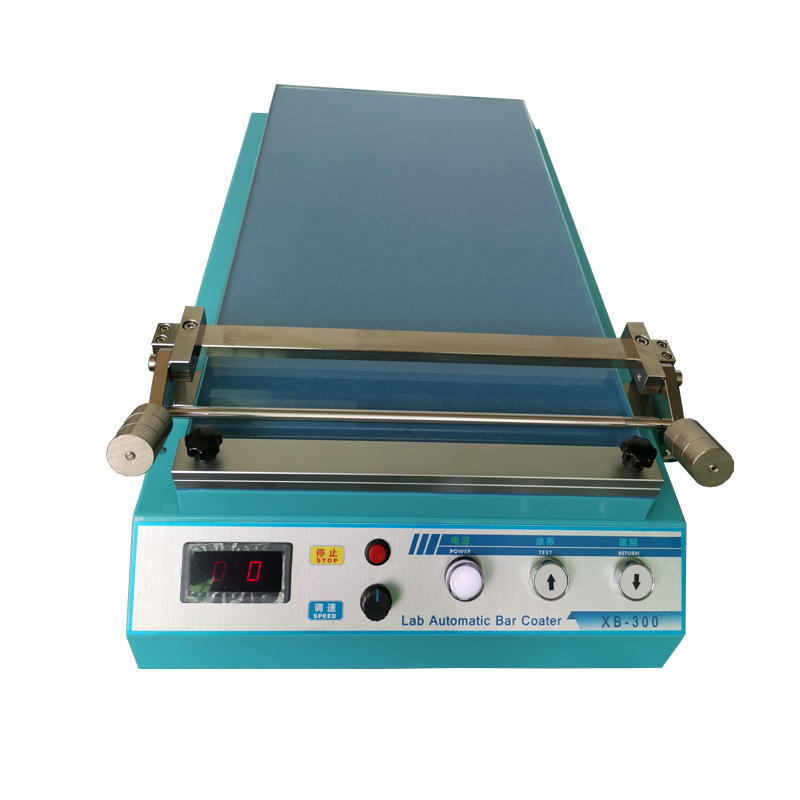

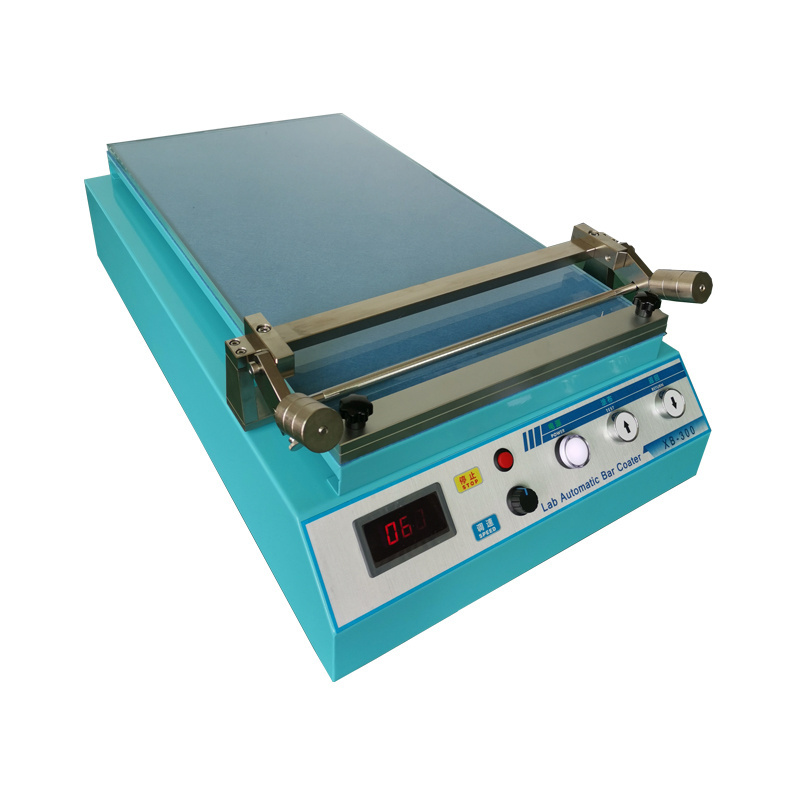

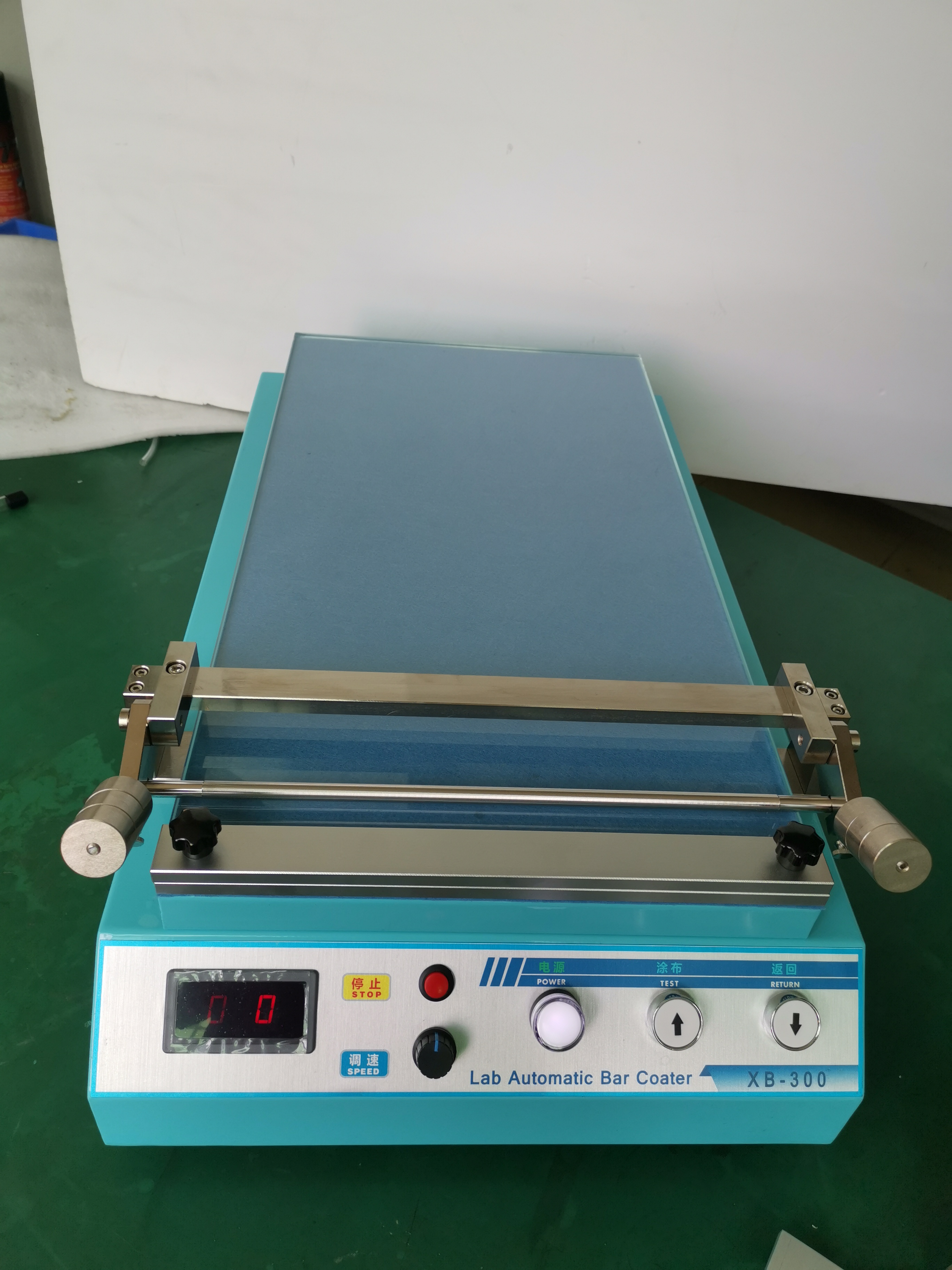

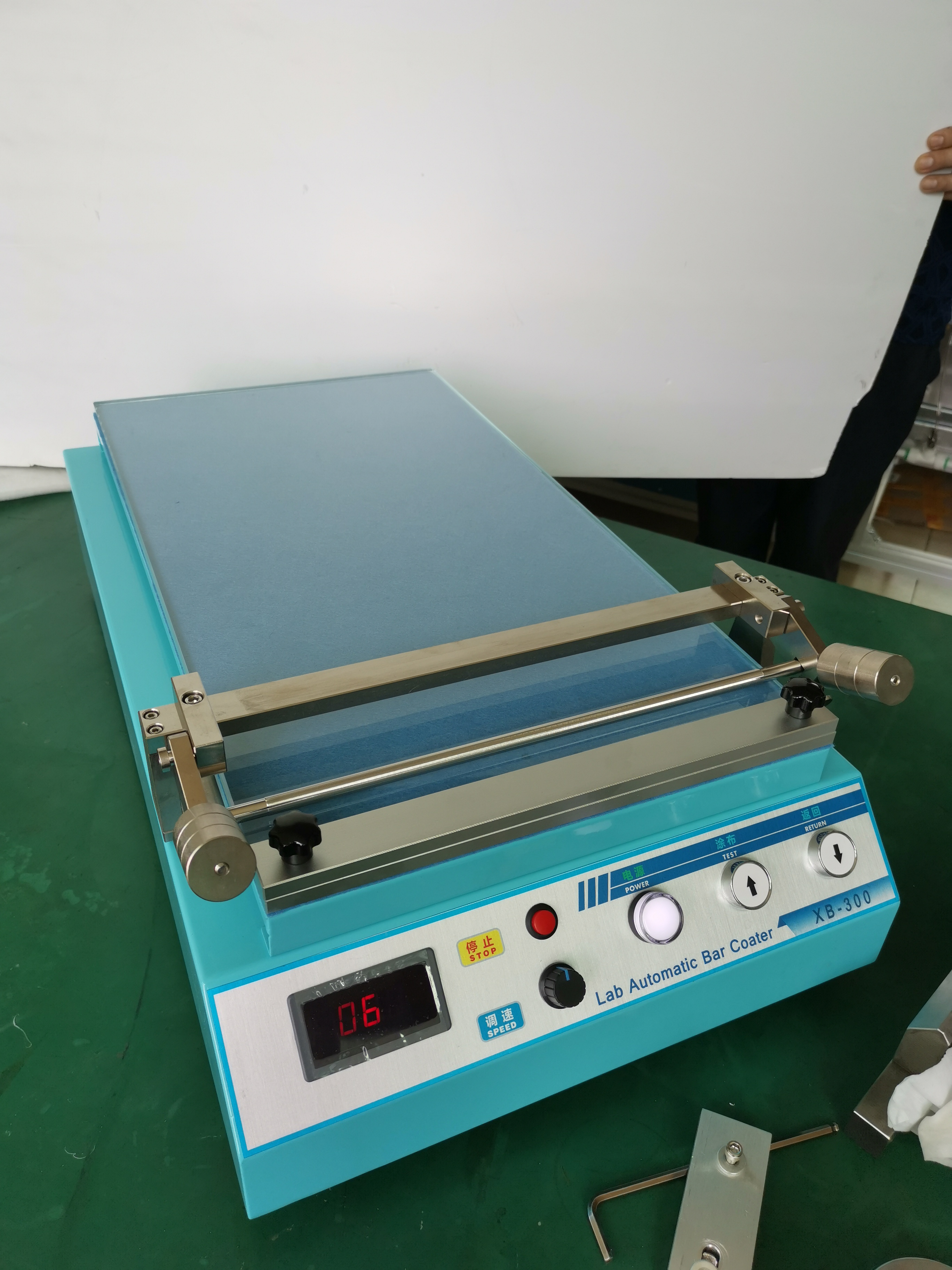

( 1 ) Digital display speed ( 2 ) Stop button ( 3 ) Speed control knob ( 4 ) Power Indicator ( 5 ) Coating button ( 6 ) Back button ( 7 ) Material fixture ( 8 ) Line bar card slot (9 ) Counterweight ( 10 ) Temered glass table

How to operation the machine ?

1. Apply the coating liquid to the front of the coating rod

2. Hold down the "↑ (coating)" button for 1 ~ 2 seconds, then let go, according to the machine

Apply the coating speed to the coating operation until it reaches the farthest end and stop automatically .

3. After the coating is completed, lift up the weights at both ends of the coating assembly

Keep the coating rod away from the coated material and remove the coated material .

4 Hold down the "↓ (return)" button for 1 ~ 2 seconds and release.

5. After the experiment is completed, loosen the twisted screws on both ends of the coating assembly to remove the coating rod and clean it to ensure that the next use will achieve a fine effect.

Non standard Automatic Scraper / Wire rod Manufacture

We would like to offer customized Automatic Laboratory Coating machine with customer's request , more technology details , welcome you to contact with us .