- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

6500*3800*2500mm

-

Max.Winding Width(mm):

-

800

-

Thickness Range(mm):

-

Cooper foil: 0.5-2.0, Aluminum foil:0.5-3

-

Length of Axis (mm):

-

1600

-

Winding Speed(rpm):

-

24

-

Counting Precision:

-

±0.5

-

Welding Method:

-

0-0.7r/min

-

Cutting Method:

-

Shearing Cut

-

Insulation Quantity:

-

10

-

Decoiler Quantity:

-

2

-

Decoiler Loading:

-

2

-

CNC System:

-

CNC

-

Applicable Industries:

-

power transformer making, Distribution transformer making

-

Product name:

-

BRJ-1600automatic copper aluminum Foil winding machine

-

Used for:

-

Power transformer , distribution transformer making

-

Thickness of foil (mm):

-

Cooper foil:0.5-2.0, Aluminum foil:0.5-3

-

Height(length) of coil:

-

300-1600mm

-

Maximum Diameter of coil (mm):

-

800

-

Winding speed:

-

0-24r/min stepless speed control

-

Shearing speed:

-

0-1.5m/min

-

Welding speed:

-

0-0.7m/min

-

Maximum tension of foil tape:

-

18000N steplesssly adjustable

-

After-sales Service Provided:

-

On-site debugging, training , online support, spare parts

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

YIBO

-

Weight (KG):

-

5000

-

Dimension(L*W*H):

-

6500*3800*2500mm

-

Max.Winding Width(mm):

-

800

-

Thickness Range(mm):

-

Cooper foil: 0.5-2.0, Aluminum foil:0.5-3

-

Length of Axis (mm):

-

1600

-

Winding Speed(rpm):

-

24

-

Counting Precision:

-

±0.5

-

Welding Method:

-

0-0.7r/min

-

Cutting Method:

-

Shearing Cut

-

Insulation Quantity:

-

10

-

Decoiler Quantity:

-

2

-

Decoiler Loading:

-

2

-

CNC System:

-

CNC

-

Applicable Industries:

-

power transformer making, Distribution transformer making

-

Product name:

-

BRJ-1600automatic copper aluminum Foil winding machine

-

Used for:

-

Power transformer , distribution transformer making

-

Thickness of foil (mm):

-

Cooper foil:0.5-2.0, Aluminum foil:0.5-3

-

Height(length) of coil:

-

300-1600mm

-

Maximum Diameter of coil (mm):

-

800

-

Winding speed:

-

0-24r/min stepless speed control

-

Shearing speed:

-

0-1.5m/min

-

Welding speed:

-

0-0.7m/min

-

Maximum tension of foil tape:

-

18000N steplesssly adjustable

-

After-sales Service Provided:

-

On-site debugging, training , online support, spare parts

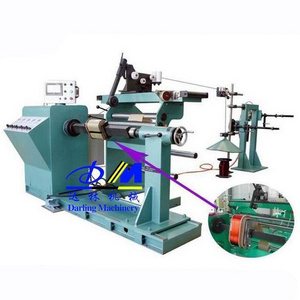

<h2> PLC Control Fully AutomaticTransformer LV foil coil winding machine </h2>

Main accessories and part supply

|

1 |

human-computer interface(HMI) |

Weinview |

|

2 |

frequency transformer |

Mitsubishi |

|

3 |

servo system |

Yaskawa |

|

4 |

PLC programmable controller |

SIEMENS or Mitsubishi, OMRON |

|

5 |

Electric elements |

Schneider of France |

|

6 |

Pneumatic components |

AIRTAC of Taiwan |

|

7 |

linear guide rail |

SBC of Korean |

|

8 |

motor |

ABB or Famous brand |

Our service

1 . Before sales service: We will give you professional instruction and help you to buy the suitable machine. Once order is confirmed, we will keep you updated on the production and delivery status so that you can be rest assured.

2 . After sales service: Our engineer will go to your factory to give you training on how to use our machine and if that is not possible for some reason we will provide a online or video training .

Foil winding machine is composed

Foil winding machine is composed

1-unrolling device

2-material leading device

3-expansion device

4-device of edge burr press, dust clean device

5-shearing device

6-edge insulation unrolling device

7-winding machine

8-welding device

9-layer insulation unrolling device

10-error correct device

11-electric control device, etc.