- Product Details

- {{item.text}}

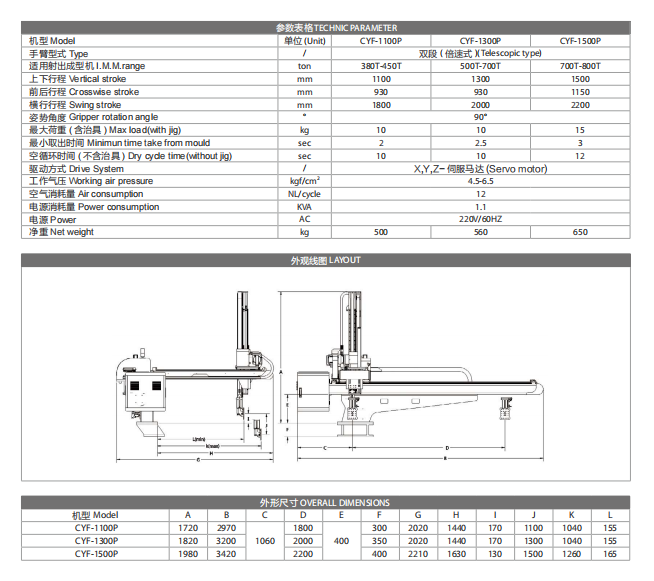

Quick Details

-

Product name:

-

Robots arms

-

I.M.M range:

-

80-380Ton

-

Type:

-

telescopic type

-

Driven System:

-

3 servo motor Panasonic/YASKAWA

-

Minimum take-out time:

-

1 sec

-

Dry cycle time(without tool):

-

2.8 sec

-

Max Load:

-

15 KG or cutoms

-

Gripper rotation angle:

-

90 -360 degree

-

Application:

-

Automation Equipment

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CHUANYI

-

Weight (KG):

-

300

-

Product name:

-

Robots arms

-

I.M.M range:

-

80-380Ton

-

Type:

-

telescopic type

-

Driven System:

-

3 servo motor Panasonic/YASKAWA

-

Minimum take-out time:

-

1 sec

-

Dry cycle time(without tool):

-

2.8 sec

-

Max Load:

-

15 KG or cutoms

-

Gripper rotation angle:

-

90 -360 degree

-

Application:

-

Automation Equipment

Product Description

CYFH THREE AXIS SERVO OPEN TYPE HIGH SPEED ROBOT SERIES

Compared with crosswise adopts frame type robot, CYH is not restricted by products' size, particularly adapt to the product whose

mold has loose-core fixture on the top.

- The traverse guide rail installs manual lubrication system, more convenient to maintain.

- Back-installed electric cabinet design improves the whole shock resistance and more stable, reduces the electronic fault.

- Wheel gear lateral plate struction and constanted overturn torque, makes tools works well. Cylinder's lifetime is longer because

of lateral cylinder piston rod no skewing.

- In-mold removal time 0.8s, arm open structure design, suitable for the removal of thin-walled products of 300T-500T high speed

injection molding machine. Such as lunch box products.

mold has loose-core fixture on the top.

- The traverse guide rail installs manual lubrication system, more convenient to maintain.

- Back-installed electric cabinet design improves the whole shock resistance and more stable, reduces the electronic fault.

- Wheel gear lateral plate struction and constanted overturn torque, makes tools works well. Cylinder's lifetime is longer because

of lateral cylinder piston rod no skewing.

- In-mold removal time 0.8s, arm open structure design, suitable for the removal of thin-walled products of 300T-500T high speed

injection molding machine. Such as lunch box products.

|

Fucntion:

|

mainly used for sorting, Cutting runner, packaging, pick and place solutions.

|

|

Advantages:

|

- Increase productivity

- Reduce manual errors - Improve efficiency and accuracy - Prevent injuries - Streamline manual and monotonous process |

|

Application field:

|

Plastic Injection Auxiliary Equipment

|

|

Industry:

|

Disposable cutlery

Thin wall Containers Pet Preform Automatic production House hood product

Auto product

Toy Food Packaging

etc..

|

FAQ

Q: What about the Warranty?

A: Warranty:

12 months warranty from delivery date

Q: What about the installation service?

A: CHUANYI Engineer would be available for in field installation and after sale service

standard / Customized robot and automation system.

standard / Customized robot and automation system.

Q: What about

delivery time

?

Shipment:Generally it is 5-10 days if the goods are in stock. or it is 10-30 days

Q: What about your machinery?

A: Our strength technical team guarantee the highest quality, precisely control and final product.

Q: Can I have a sample order?

A: Our strength technical team guarantee the highest quality, precisely control and final product.

Q: Can I have a sample order?

A: Yes, we welcome sample order to test and check quality.

Q. Do you have any MOQ limit?

A: Low MOQ, 1pc for sample checking is available.

Hot Searches