- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customer's Requirement, 110v-440v,50hz ,60hz.

-

Power:

-

22kw,30kw,45kw,55kw,75kw,90kw,120kw

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

2200*1000*1900mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material quality:

-

SS304

-

Production capacity:

-

100-2000kg/h

-

warranty:

-

2 years

-

certification:

-

CE ISO9000

-

Energy:

-

electricity, oil diesel, gas, steam

-

Motor brand:

-

Siemens, ABB or Chinese brand

-

Shapes:

-

Various upon clients' demands.

-

After Warranty Service:

-

Video technical support

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

bright

-

Voltage:

-

Customer's Requirement, 110v-440v,50hz ,60hz.

-

Power:

-

22kw,30kw,45kw,55kw,75kw,90kw,120kw

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

2200*1000*1900mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material quality:

-

SS304

-

Production capacity:

-

100-2000kg/h

-

warranty:

-

2 years

-

certification:

-

CE ISO9000

-

Energy:

-

electricity, oil diesel, gas, steam

-

Motor brand:

-

Siemens, ABB or Chinese brand

-

Shapes:

-

Various upon clients' demands.

-

After Warranty Service:

-

Video technical support

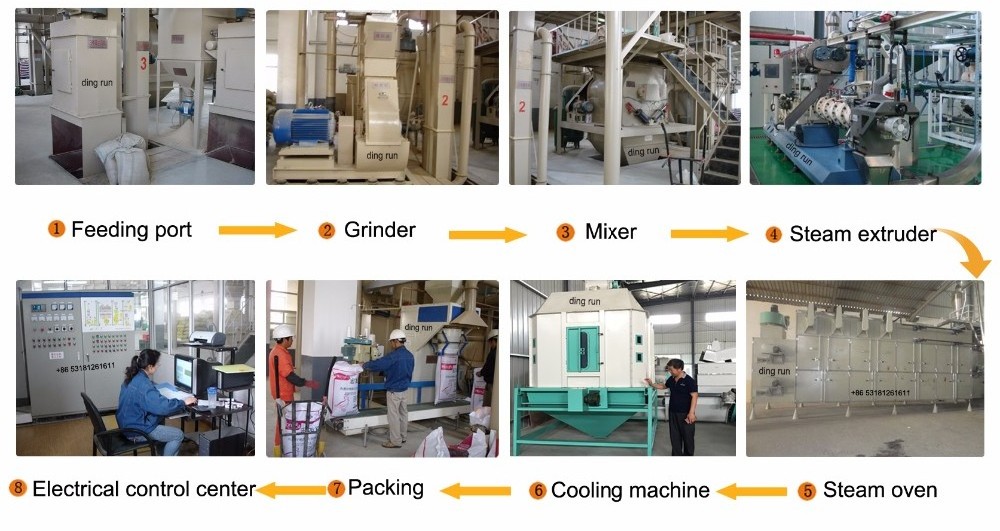

automatic fish feed food pellets machine production line fish feed processing extruder equipment supplier

Fish feed machine is suitable to make dry and wet type fish food pellet (catfish, aquarium, Tilapia, Freshwater fish and tropical fish etc.)

1). All fish food equipments are made of stainless steel.

2). The fish food whole line fully continuous and automatic.

3). Bright provide basic fish food formula according to your require.

4). The final fish food shapes and sizes can be various by changing the mould.

5). Supply different size mould free of charge.

6). Packing machine could be supplied to work with the fish feed production line (depending on your require)

Simple operation automatic fish production line is widely used for producing grains into high grade aquatic feed pellets for fish,catfish,shrimps,crabs,etc. The fish feed can float on the water surface without dissolution for over 12 hours.

Flow chart:

mixing→extruding→drying→flavoring →cooling→packaging

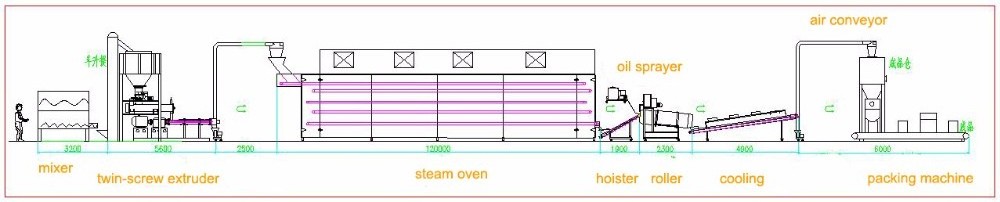

Flow chart diagram:

Our engineer could design the layout drawing according to your dimension of the factory for the fish feed machines

Machine parameters:

|

Model

|

Installed Power

(kw)

|

Power Consumption

(kw)

|

Capacity

(kg/h)

|

Dimension

(m)

|

|

DSE65

|

74

|

52

|

120-180

|

17*1.2*2.2

|

|

DSE70

|

95

|

70

|

200-300

|

20*1.5*2.2

|

|

DSE75

|

110

|

82

|

250-400

|

26*1.5*2.2

|

|

DSE85

|

139

|

104

|

400-800

|

28*3.5*4.3

|

|

DSE90

|

132

|

75

|

800-1200

|

28*3.5*4.3

|

|

DSE95

|

165

|

90

|

1500-2000

|

35*3.5*4.3

|

|

DSE120

|

469

|

380

|

2000-2500

|

45*20*22

|

|

DSE135

|

712

|

570

|

3000-3500

|

50*20*25

|

Raw material:

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

Sample of fish feed pellet:

Equipment list in the fish feed production line:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

|

Name

|

grinder

|

|

Usage

|

corn, sorghum, wheats, beans, cottonseed meal,canola,etc.It can do coarse grinding and fine grinding processes

|

|

Type

|

Hammer Mill

|

|

Motor

|

7.5kw, 15kw, 22kw, 55kw, 75kw and so on

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

stainless steel, carbon steel

|

|

Name

|

Mixer

|

|

Usage

|

To mix the raw materials evenly, fast speed, no leakage.

|

|

Type

|

including Single axle and double shaft mixer

|

|

Motor

|

3kw, 4kw, 7.5kw etc.

|

|

Capacity

|

20kg/time, 50kg/time, 100kg/time, 200kg/time, 500kg/time etc.

|

|

Material

|

stainless steel, carbon steel

|

|

Name

|

Twin screw extruder(wet type/dry type)

|

|

Usage

|

To extrude the raw materials and make them to the required shape and size of the fish feed pellets by mould

|

|

model

|

DSE65, 70, 75, 90, 95, 120, 135

|

|

Motor

|

22kw, 30kw, 55kw, 75kw, 90kw, 110kw etc.

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

Screw materials 38CrMoAl

stainless steel, carbon steel |

|

Name

|

Dryer (oven)

|

|

Usage

|

the expanded food go through the “s” passage, to be dried to increase the self life.

|

|

Type

|

electrical, steam, gas fired, diesel fired heating type

|

|

Motor

|

KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10 etc.

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

stainless steel, carbon steel

|

|

Name

|

Flavoring machine

|

|

Usage

|

To mix the oil and flavors on the surface of the fish feed

|

|

Type

|

single and double flavoring drum

|

|

Motor

|

0.75kw

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

stainless steel

|

|

Name

|

Packaging machine

|

|

Usage

|

To pack the fish feed with required weight

|

|

Flowing Process

|

Manual Bag placing→Automatic filling→Automatic weighing→ Automatic bag conveyor→Automatic bag sewing or heat sealing

|

|

Weight range

|

1-5kg/bag, 5-25kg/bag, 25-50kg/bag

|

|

Material

|

stainless steel, carbon steel

|

|

Type

|

Automatic

|

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit and check the machine to my factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment.

Q: How about the after-service?

A: We will send 1 engineer to the buyer’s factory for a 10-day period installation and training to the operators.

Q:do you supply any formula to buyer?

A:yes, we supply formula to buyer.

1.Use anti-rust oil to wipe the equipment for floating fish feed pellet granulator making machine in bangladesh

2.air cushion film packaging equipment for small fish feed mill plant

3.with a wooden box for the final step of packaging for fish feed manufacturing machine