New environmentally friendly technology 0 formaldehyde

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

TongFeng

-

Material:

-

PVC Resin

-

Product name:

-

PVCceiling

-

Usage:

-

Interior Decoration Materials

-

Surface:

-

Powder Coating

-

Color:

-

Customized Color

-

Key word:

-

Fireproof Materials

-

Type:

-

Modern Wall Panel

-

Size:

-

Customized Size

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Free spare parts

-

Project Solution Capability:

-

graphic design

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

TongFeng

-

Material:

-

PVC Resin

-

Product name:

-

PVCceiling

-

Usage:

-

Interior Decoration Materials

-

Surface:

-

Powder Coating

-

Color:

-

Customized Color

-

Key word:

-

Fireproof Materials

-

Type:

-

Modern Wall Panel

-

Size:

-

Customized Size

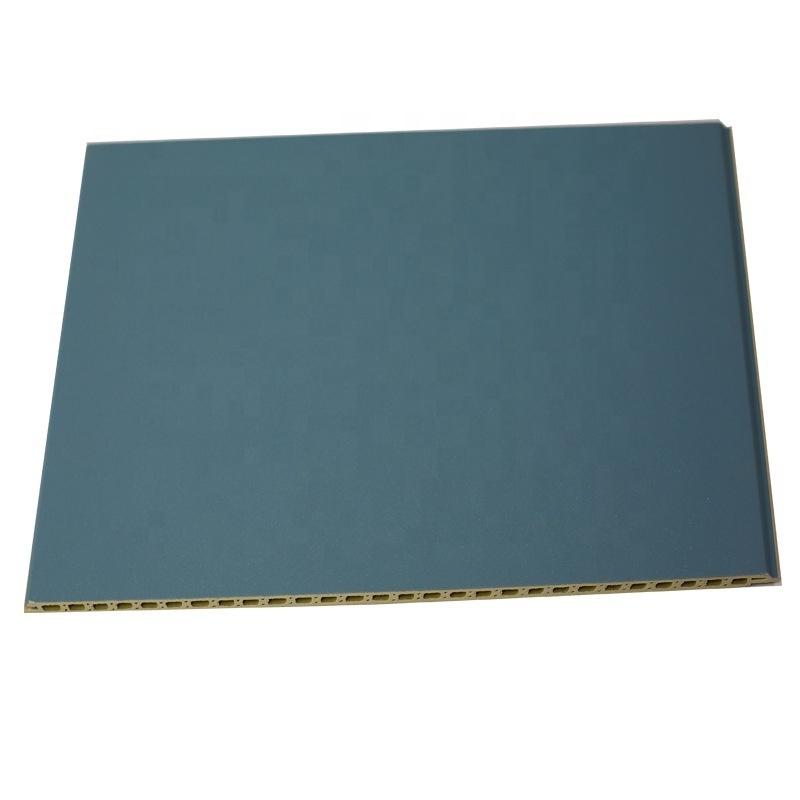

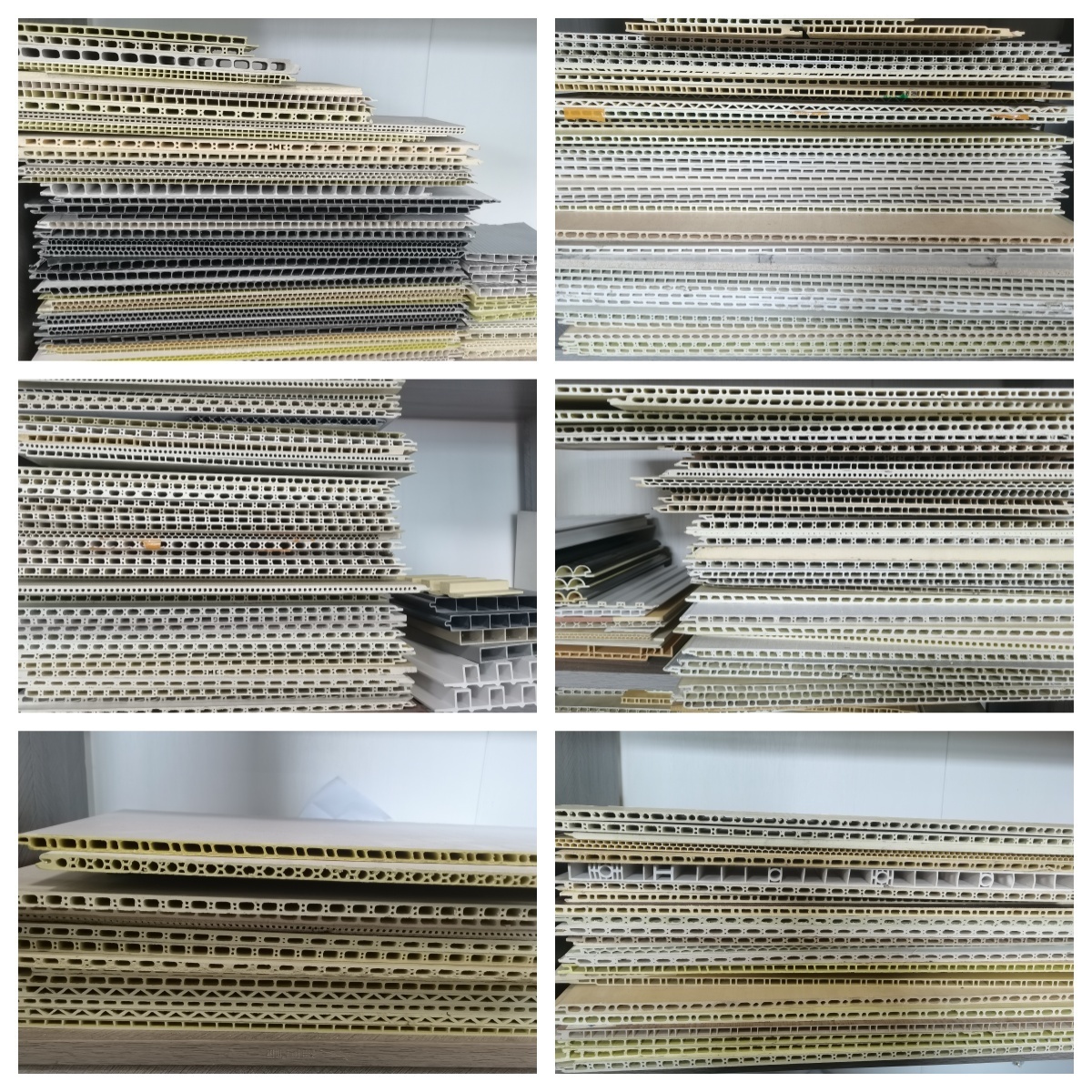

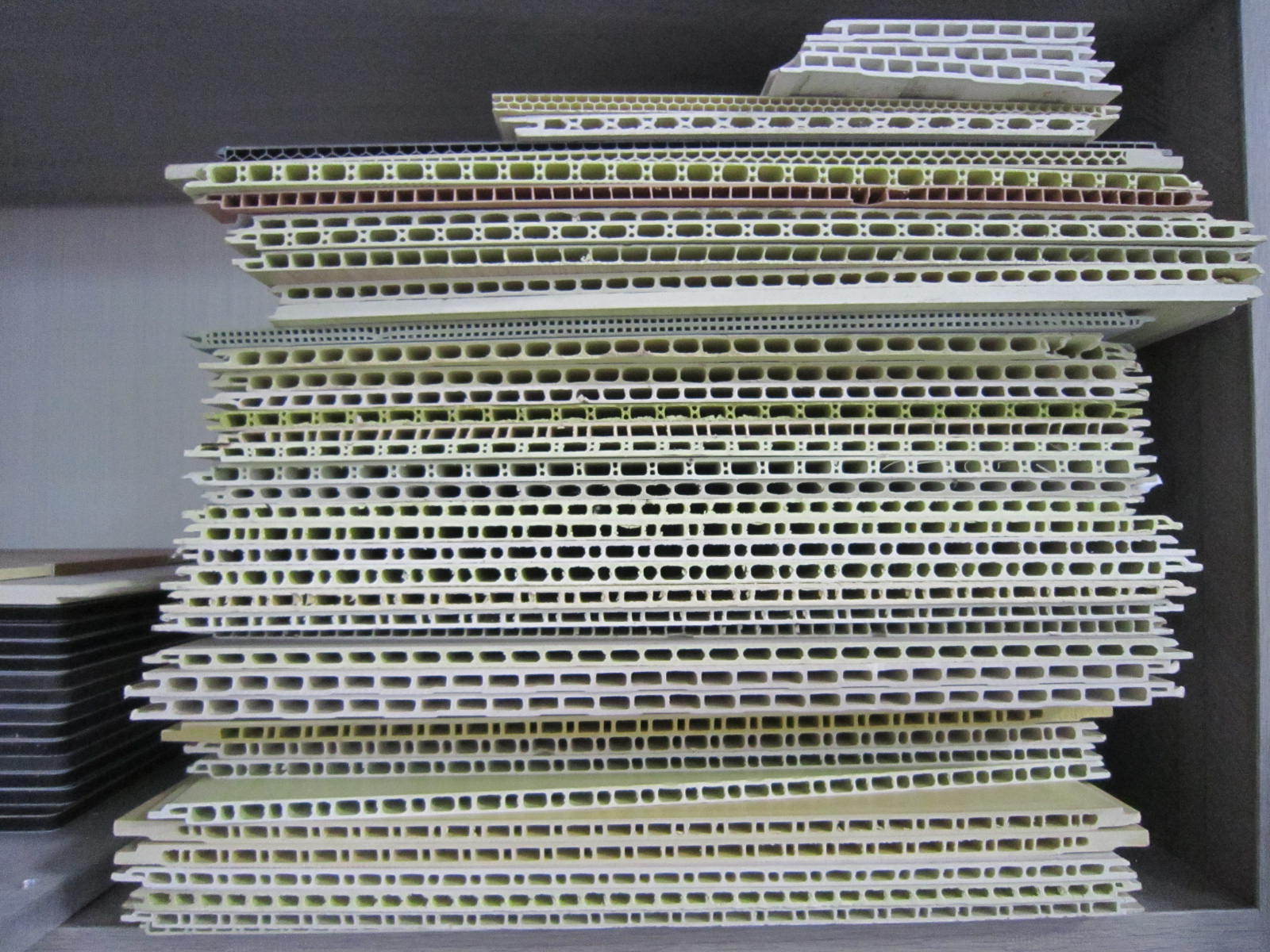

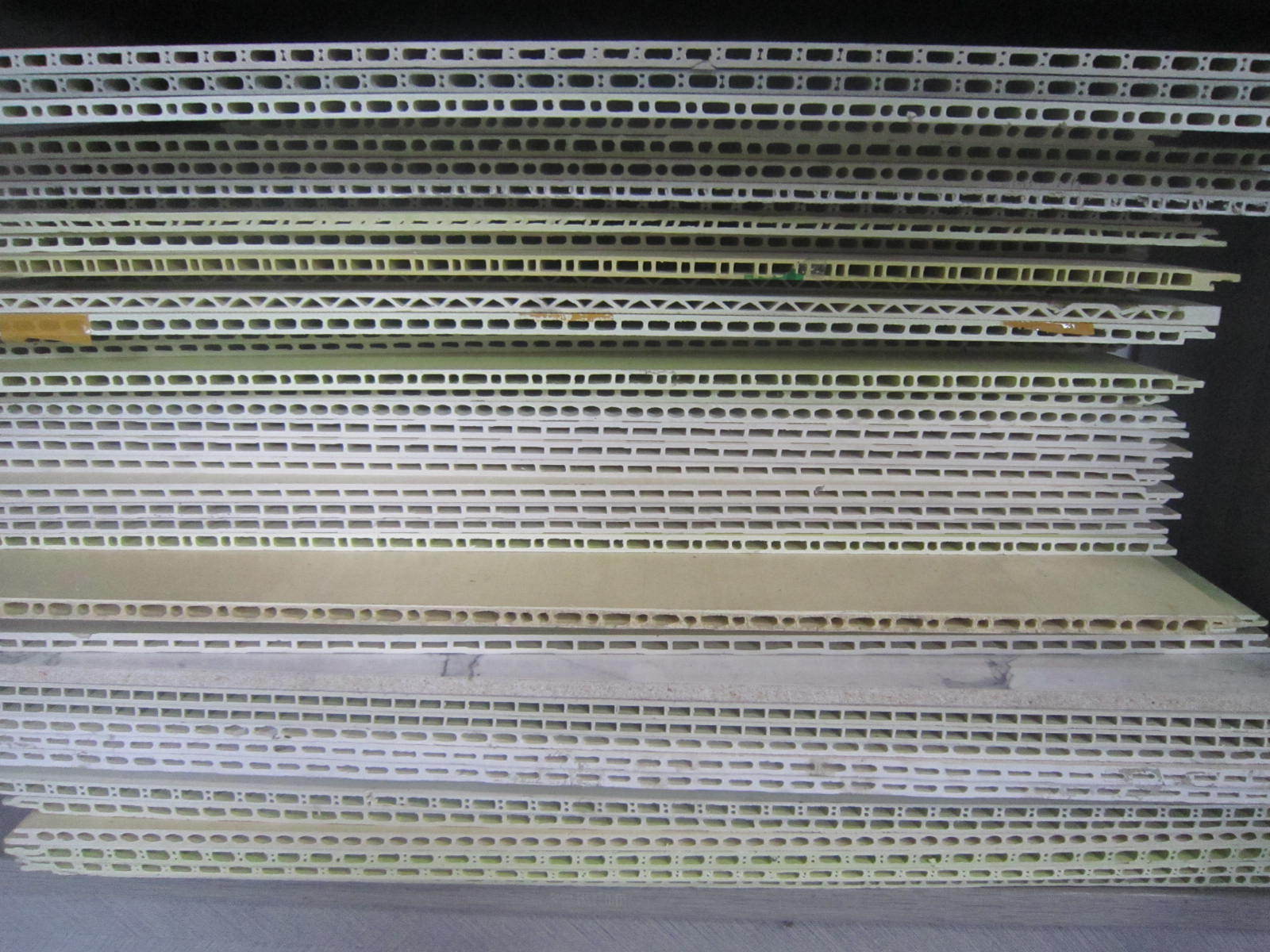

PVC panel cladding panel indoor waterproof wood plastic ceiling wall panel

|

Product Name

|

Decoration Wall Panel

|

|

|

|

|||

|

Material

|

WPC/PVC

|

|

|

|

|||

|

Size

|

Customized

|

|

|

|

|||

|

Color

|

Customized

|

|

|

|

|||

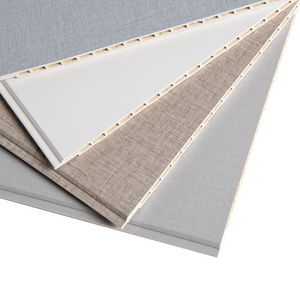

Product Feature

1.100% recyclable, environmentally friendly, saving forest resources

2. Has the look of natural wood, but no wood issues

3. Waterproof, non-rotting, proven in salt water conditions

4. Barefoot friendly, non-slip, no cracking, no warping

5. No painting, no glue, low maintenance

6. Weather resistance, suitable for -40° C to 60° C

7. Anti-insect and anti-mildew

8. Available in different colors

9. Easy to install and clean

Products Description

No damage to the wall, easy installation with one click and one buckle, free splicing

Waterproof and mildew proof

High density, good coating, water-blocking effect, moisture-proof and not prone to mold

Product Paramenters

Monochrome series

:

Porcelain white/Matte white/Off-white/Peach pink/Lemon yellow/Hermès orange/Sky blue/Earth green/Galaxy gray/Khaki gray/Light blue/Dark blue/Matte black

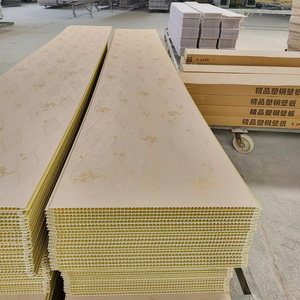

Wood grain series

:

N

ew apple wood/Olympic oak/Synchronized Silver Oak/Oak/Mocha sandalwood/Rosewood/New Suxiangtang/Fraxinus mandshurica/Technology wood/

Plane tree/Fish petrified wood/Straight grain technical wood/

sycamore wood/Yellow cedar/Straight grain teak/Silver pear/Straight grain pine

Textile fabric series:

Burlap pattern/White fabric art/European stripes/Vertical flowers/White brushed/Silver brushed/Black brushed/Wall curtain/Fabric pattern/Yaxin fabric art/Fabric pattern /Orchid rhyme/Cloth pattern/Blue Morandi/Cloth pattern/Simple fabric art/Impression Trail-White/Spring embroidery stitch/Magic gold fabric/Jingwei fabric art/Pearl fabric/

Golden silk fabric/Silver filigree fabric/Light gray fabric pattern/Mocha pattern/Linen fabric/Elegant linen/Golden silk cloth pattern/Straight grain fabric/Filigree art

Marble series:

Jazz white/Golden beige/Black gold stone/Italian black gold flower/Jade ice flower/HD wood/Huang Bingyu/Turkish gold wire/Mottled patina/Fish belly white/Anna beige/Qiu gray white

Applicable to

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

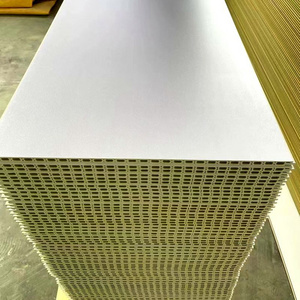

Manufacturing Technique

Raw material preparation:

This is the first step in the production process where raw materials and other additives are prepared to be collected and stored in designated areas. The raw materials are then weighed and mixed according to a predetermined recipe to ensure the consistency and quality of the final product.

Mix the ingredients:

Once you have the ingredients ready, mix them together in a high-speed mixer. The blender ensures that all ingredients are evenly distributed and thoroughly mixed. This step is critical to achieve the desired physical and chemical properties.

Extrusion:

After the raw materials are mixed, they are fed into the extruder. The extruder heats and melts the material, forming a continuous molten fluid. The melt is then forced through the mold, shaping the material into the contours of the desired wall panel.

Wood grain coating:

After extrusion, a specialized coating is used to imprint the wood grain pattern on the surface. The coating is applied with a roller or spray gun to create a realistic wood look on the surface.

Cutting:

After the woodgrain laminate is added, it is cooled and cut to the desired length. The cutting process is usually automated, ensuring that all baseboard boards are the same length and size.

Quality Control:

Throughout the entire production process, quality control measures are taken to ensure that the final product meets all specifications and requirements. Samples are taken and tested for strength, durability and other properties.

Packaging and Shipping:

The final step in the production process is packaging and preparing it for shipping. Baseboard boards are stacked, wrapped in protective material, and loaded into trucks or containers for shipment to customers.

Why Choose Us

High density

Our WPC wood plastic wall panels are made of high-density polyethylene and solid wood fibers, which have good stability and strength compared to wood. Will not crack and twist, suitable for indoor and outdoor use.

Excellent performance

The WPC wood plastic wall panels we develop are waterproof, moth-proof, and corrosion-resistant. It is an ideal substitute for current solid wood materials and also has the function of thermal insulation.

Environmentally friendly materials

WPC wood plastic wall panel is an ideal environmentally friendly building material choice, it is a renewable energy source, easy to clean and low maintenance. The product complies with the concept of sustainable development, is reusable and simple to maintain, which is a very environmentally friendly building material.

Lightweight and convenient

Lightweight materials make your construction project easier. Our wood plastic wall panels are easy to transport and install, saw,planed and drilled in a variety of elegant designs and patterns.

Product packaging

FAQ

1.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

Always final Inspection before shipment;

2.What can you buy from us?

Wpc wall panel/Grille wall panel/Ceiling/Foam board/Bamboo wood fiber board/Pvc profile/Door frame/Decoration line/Extrusion mould/Pvc upvc profile mould/Wall panel mould/Pe wood plastic mould/Foam board mould/Grille wall panel mould/Door panel mould/Pvc door and window co-extrusion mould/Plastic extrusion mould/pvc Pipes extrusion moulds

3.Why should you buy from us not from other suppliers?

Rich extrusion manufacturing experience; self-produced and sold, with competitive price; mold quality assurance;

Advanced processing equipment, comprehensive debugging and after-sales service; long-term free technical guidance; quality inspection report.

4. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery; Accepted Payment Currency:USD,EUR,CNY; Accepted Payment Type:

T/T,L/C,Credit Card,PayPal,Western Union.

T/T,L/C,Credit Card,PayPal,Western Union.

Hot Searches