- Product Details

- {{item.text}}

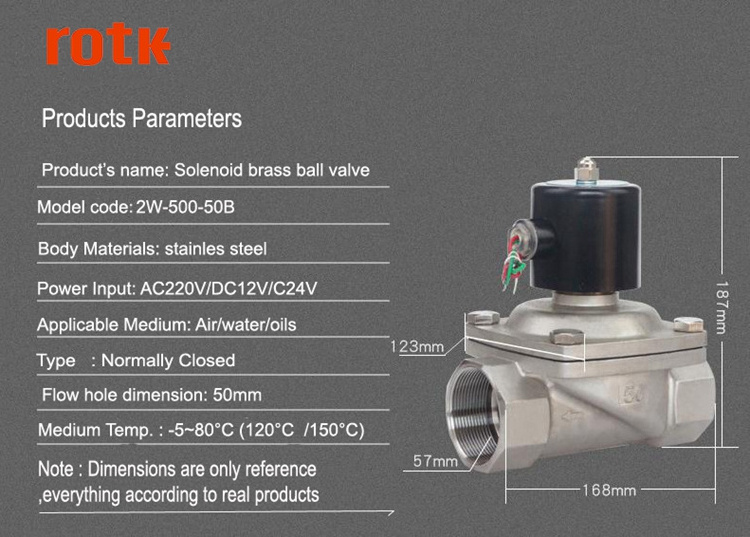

Quick Details

-

Brand Name:

-

RotK

-

Product name:

-

Solenoid Valve

-

Body Material:

-

Stainless Steel

-

Power input:

-

AC220V,DC12V,DC24V

-

Applicable medium:

-

Air/water/oils

-

Type:

-

Normally closed, solenoid valve

-

Flow hole dimension:

-

50mm

-

Medium temperature:

-

-5-80℃(120℃/150℃)

-

Note:

-

Dimensions are only reference,everything according to real product

Quick Details

-

Port Size:

-

Standard, 1/2' -2'(DN15-50)

-

Place of Origin:

-

Guangdong, China (Mainland)

-

Model Number:

-

2W-500-50B

-

Brand Name:

-

RotK

-

Product name:

-

Solenoid Valve

-

Body Material:

-

Stainless Steel

-

Power input:

-

AC220V,DC12V,DC24V

-

Applicable medium:

-

Air/water/oils

-

Type:

-

Normally closed, solenoid valve

-

Flow hole dimension:

-

50mm

-

Medium temperature:

-

-5-80℃(120℃/150℃)

-

Note:

-

Dimensions are only reference,everything according to real product

| · About Solenoid Valve · |

Safety precautions:

1, first check whether the solenoid valve is consistent with the selection parameters, such as supply voltage, medium pressure and pressure difference, especially the power supply, if it is wrong, it will burn the coil.

2. Before installing the solenoid valve, all kinds of dust in the pipe are removed first. And install the filter, when connecting the pipeline, pay attention to the leak belt winding not to exceed the tooth end.

3, the normal installation method light reference to the lower drawing.

4, the battery valve should be installed horizontally, not upside down or erected.

5, the battery valve installation should be equipped with manual cutting valve, at the same time, there should be a bypass to facilitate the maintenance of battery valve failure.

6, if the medium will have water hammer phenomenon, then the battery valve with the function of waterproof hammer should be selected or the corresponding precaution measures should be taken.

7, often open and normally closed battery valve can not be used interchangeably.

8, solenoid valve does not work: check whether the power line connection, adverse re wiring and plug; check whether the power supply voltage range to the normal position, within the scope of work; check whether the coil connecting - re welding; coil short - to replace the coil; solenoid valve working pressure is not suitable for - pressure - adjusting or replace the match; the battery temperature is too high, the replacement valve fluid commensurate with impurities; the main spool valve and the moving core battery card dead - cleaning, if the seal is damaged, replace the seal and install the filter; the liquid viscosity is too large, too high frequency and life has to replace the product.

9, battery: the main spool valve can not be closed or sealed moving core has been damaged, replace the seals; fluid temperature, viscosity is too high, the replacement of a solenoid valve mouth; impurities into the main spool valve or battery moving core - cleaning; working frequency is too high or the life has changed to - selected products or updates.

10, other cases: internal leakage -- check whether the seal is damaged, whether the spring is assembled poorly, and let it go out, which is loose or seal has been damaged, tightening screws or replacing seals. There is noise when electrified -- fastening and loosening and tightening on the head. The voltage fluctuation is not allowed within the allowable range, and the voltage is adjusted. Iron core suction surface impurities or uneven, timely cleaning or replacement.

| · Product show · |

| · |