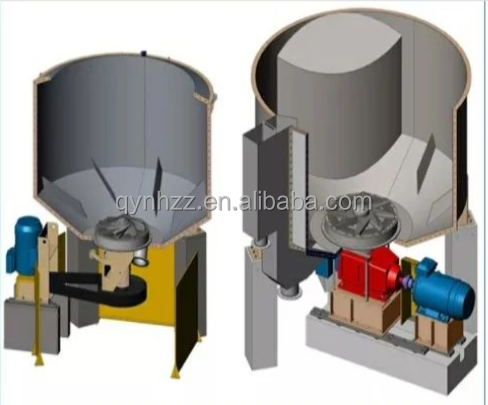

The tank is made by welded steel,outside of mouth is ultra high strength steel,which used to strengthen tank, in the bottom of cone have deflector, which can make the paper pulp reflux circulating. In the bottom of tank is impurity discharge outlet."D" type hydropulper has changed the way of flow ,make the material contact more quickly with the rotor ,and reduce bearting time greatly,and improve production capacity in the condition of without increasing the power and volume .

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

NH

-

Voltage:

-

380V, 380V/50Hz

-

Dimension(L*W*H):

-

as your choice

-

Weight:

-

100 kg

-

Core Components:

-

rotor

-

Product name:

-

Waste paper recycling line pulper in paper processing machine

-

Function:

-

To break the waste pulp

-

Raw material:

-

Waste paper ,virgin pulp

-

Volume:

-

3-25m3 as your requiremen

-

Body of equipment:

-

SUS ,cast iron

-

Drive way:

-

AC frequency conversion speed

-

Bearing:

-

NSK ,FAG ,INA available

-

Concentrate:

-

12-18%

Quick Details

-

Type:

-

Pulping Equipment

-

Production Capacity:

-

95%

-

Max. workable width:

-

/

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

NH

-

Voltage:

-

380V, 380V/50Hz

-

Dimension(L*W*H):

-

as your choice

-

Weight:

-

100 kg

-

Core Components:

-

rotor

-

Product name:

-

Waste paper recycling line pulper in paper processing machine

-

Function:

-

To break the waste pulp

-

Raw material:

-

Waste paper ,virgin pulp

-

Volume:

-

3-25m3 as your requiremen

-

Body of equipment:

-

SUS ,cast iron

-

Drive way:

-

AC frequency conversion speed

-

Bearing:

-

NSK ,FAG ,INA available

-

Concentrate:

-

12-18%

D-type Hydrapulper Pulper Equipment

|

Advantage

:

1. Strong ability to disintegrate ;

2. Short pulping time ;

3. Easy operation and maintenance ;

4. Continuous, intermittent discharge ;

5. Only dissociation of the slurry without cutting ;

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model

|

NHD0

|

NHD1

|

NHD2

|

NHD3

|

NHD5

|

NHD8

|

NHD10

|

NHD15

|

|||||||

|

Volume (m³)

|

0.5

|

1

|

2

|

3

|

5

|

8

|

10

|

15

|

|||||||

|

Inner diameter of the tank (mm)

|

D1000

|

D1200

|

D1600

|

D1800

|

D2400

|

D2500

|

D2700

|

D3500

|

|||||||

|

Capacity (t/d)

|

3-5

|

6-10

|

12-16

|

18-26

|

26-34

|

45-60

|

60-80

|

80-100

|

|||||||

|

Rotor diameter (mm)

|

D360

|

D450

|

D500

|

D540

|

D700

|

D800

|

D1000

|

D1250

|

|||||||

|

Rotor speed (r/min)

|

700

|

650

|

490

|

480

|

450

|

336

|

320

|

320

|

|||||||

|

Slurry tube diameter (mm)

|

D80

|

D100

|

D125

|

D150

|

D200

|

D250

|

D250

|

D325

|

|||||||

|

Inlet pipe diameter

(mm)

|

D50

|

D50

|

D65

|

D60

|

D80

|

D80

|

D80

|

D100

|

|||||||

|

Concentration(%)

|

2.5-4.5

|

|

|

|

|

|

|

|

|||||||

|

Motor (kw)

|

4/11

|

4/22

|

4/37

|

6/45

|

6/55

|

6/75

|

9/90

|

6/160

|

|||||||

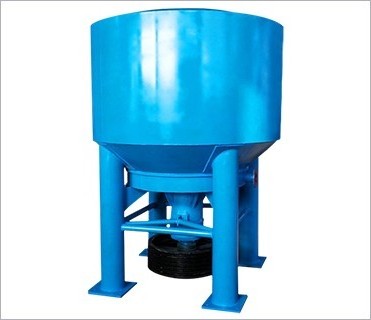

D Type Hydrapulper Paper Production Equipment for Paper Mill, which improves the work efficiency, and it can be used for pulping waste paper & wet strength paper. D Type Hydrapulper is mainly used to crushing pulp board, wastepaper, deinking, and pulp purification. Through dissociating, it can maximum make the paper's fiber dissociating into fiber bundles or single fibers, while at the same time, it can maximize maintain impurity's shape and strength.

Tank

Rotor

Rotor and outflow pulp tray locate above the bottom of the tank ,forming a low pressure area around the outflow pulp tray,to reduce the contact between impurities and cutter or sieve plate ,and prolong the service life of the cutter and seive plate .

Cutter blade

The design of cutter blade between cutter and sieve plate prevents the twining of waste materials like wire and weaving,and reduce running current.

Sieve plate

Sieve plate used for screening paper pulp.

Cutter blade

The design of cutter blade between cutter and sieve plate prevents the twining of waste materials like wire and weaving,and reduce running current.

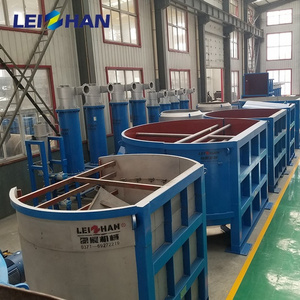

Have shippied the goods to USA, Australia, Russia, Indonesia, Uzbekistan, Tajikistan, Nigeria, Uganda, Ghana,Saudi Arabia, Kenya,Pakistan, Egypt, Bhutan,Fiji, Brazil, Paraguay, Syria, Libya etc.

NH Paper Machinery Industrial Group is a leading professional paper machine manufacturer in China, which specializes in making machine, paper making machine and all kinds of paper machine components manufacturing. Based on the development of local market ,we are growing to professional paper mill solution provider. NH Paper Machinery Industrial Group fully implement the guideline in business-"survival depends on quality and service ,market rely on price and brand."

Our main products are a full set of new and second hand paper making equipment with a maximum net with of 6000mm and a working speed of 700m/min.It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

According to the process, divided into different workshop .With strict quality control system to ensure the finished product quality .

Our factory have over 30 years history , have developed good and stable relationship with customers for all over the world based on our product good quality ,worker’s service and best price . There are photos of part of customer visit.

NH Paper Machinery Industrial Group Co., Ltd.

Mob/WhatsApp/Wechat:

086-157 2152 2521

Web: http://www.qynhgroup.com/