- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

diesel engine

-

Dimension(L*W*H):

-

227*62*123cm

-

Weight:

-

980 kg

-

color:

-

as request

Quick Details

-

Max. Capacity:

-

800 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

none

-

Voltage:

-

diesel engine

-

Dimension(L*W*H):

-

227*62*123cm

-

Weight:

-

980 kg

-

color:

-

as request

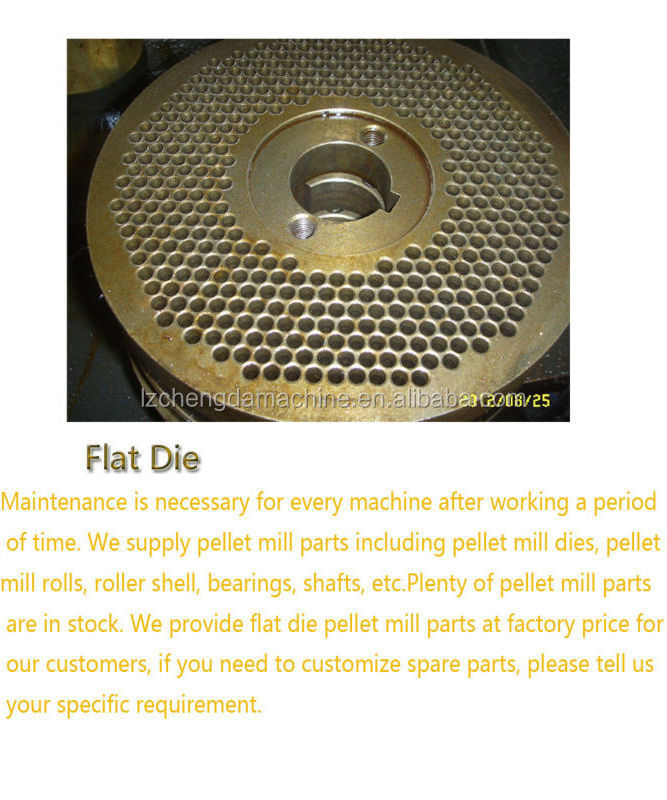

Flat Die Pellet Mill Features

1. Driven by a diesel engine making pellets production possible especially in the rural area with shortage supply of electricity.

2. Low Cost: The low cost of diesel fuel results in low cost energy production. Cheap energy will also result in decreased production costs and help you save a lot of money in buying raw material.

3. Diesel easy to get: Among all the fossil fuels, diesel is the most easily available one around the world. You can find it almost everywhere.

4. Cost-effective price and can meet your requirement in pellet production.

5. Pellets size can be from 2.5-10mm upon your requirement. When making different size, you just need to change the die mould.

| Model No. | Diesel Engine | Feed output | Wood output | N/G weight(kg) | Pellet diameter | Packing Size(cm) |

| KL120A | 8HP Diesel Engine | 60-100 | 40-60 | 120/140 | 2.5-10mm | 87*44*73 |

| KL150A | 8HP Diesel Engine | 90-120 | 50-90 | 120/140 | 2.5-10mm | 76*43*71 |

| KL200A | 15HP diesel engine | 200-300 | 110-140 | 280/310 | 2.5-10mm | 118*56*95 |

| KL230A | 22HP diesel engine | 300-400 | 150-190 | 280/310 | 2.5-10mm | 118*56*95 |

| KL260A | 35HP diesel engine | 400-600 | 220-280 | 450/480 | 2.5-10mm | 184*70*116 |

| KL300A | 55HP diesel engine | 600-800 | 280-320 | 520/560 | 2.5-10mm | 220*60*123 |

| KL360A | 55HP diesel engine | 700-900 | 300-380 | 600/620 | 2.5-10mm | 227*62*126 |

| KL400A | 55HP diesel engine | 900-1100 | 400-550 | 750/780 | 2.5-10mm | 227*62*126 |

What is the terms of warranty and spare parts?

Our pellet mills are guaranteed with 1 year quality assurance from the date of goods shipment.

When we are talking about spare parts for a pellet mill, by and large, we are talking about die, roller and bearing. Practically, that how often you will need to renew spare parts is depending on what raw material you are making pellets from. Apparently, compared with making straw pellets, pellet mill that are making wood pellets requires a higher frequency for changing spare parts. We supply clients with high quality pellet mill dies, rollers, bearings and other parts. Clients are available to order at anytime. If you need spare parts, please contact me or test message.

What can I do when my Pellet mill can not produce pellets?

A: New flat die pellet mill in first use may not produce pellets, because of the low smoothness of mould and bad cooperation in new devices. After using oily material for a period, the pellet machine can run smoothly.

B: The clearance between rollers and dies is too large. You can tighten the screw to narrow the gap to 1.5-2.5 mm.

C: Necessary steps to update a new die or roller shell because of wear and tear caused by long-term service.

D: The material is too wet or too dry, resulting in low productivity. You’d better increase or decrease the moisture to proper rate, generally 14%-16% in raw material.

Do I have to go to your factory for atutorial of learing how to operate a pellet mill?

It's not necessary. As 7/24 email and phone call service is available, I am ready to answer your any specific questions regarding to our machinery and pellet mill in particular. In addition, we prepare the teaching videos in terms of installation, lubrication, trial running, parts replacements and so forth.