- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

184 kN

-

Theoretical Shot Volume(cm³):

-

1786 cm³

-

Injection Rate (g/s):

-

90 g/s

-

Injection Weight (g):

-

2078 g

-

Screw diameter (mm):

-

83 mm

-

Weight (KG):

-

15000 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

710 mm

-

Brand Name:

-

Comark

-

Power (kW):

-

45.2 kW

-

Product name:

-

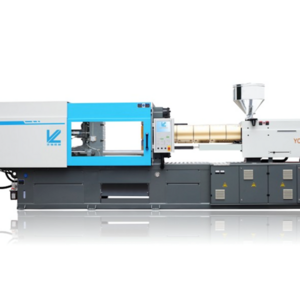

Factory Price Small Injection Molding Machine For PET Product

-

Keyword:

-

Injection Molding Machine

-

Plastic Type:

-

Thermoplastic

-

Application:

-

Inserting Plastic Products

-

Usage:

-

Injection Molding Machine Making Plastic Injection

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

-

BRAND:

-

Comark

-

Color:

-

As your requirement

-

Machiner Dimensions(mm):

-

7.2*1.65*2.3m

-

Used for:

-

PE PET PVC Plastic Molding

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

510mm

-

Distance between Tie Bars(Height)(mm):

-

510mm

-

Ejector Stroke(mm):

-

210 mm

-

Ejector Force(kN):

-

184 kN

-

Theoretical Shot Volume(cm³):

-

1786 cm³

-

Injection Rate (g/s):

-

90 g/s

-

Injection Weight (g):

-

2078 g

-

Screw diameter (mm):

-

83 mm

-

Weight (KG):

-

15000 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

710 mm

-

Brand Name:

-

Comark

-

Power (kW):

-

45.2 kW

-

Product name:

-

Factory Price Small Injection Molding Machine For PET Product

-

Keyword:

-

Injection Molding Machine

-

Plastic Type:

-

Thermoplastic

-

Application:

-

Inserting Plastic Products

-

Usage:

-

Injection Molding Machine Making Plastic Injection

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

-

BRAND:

-

Comark

-

Color:

-

As your requirement

-

Machiner Dimensions(mm):

-

7.2*1.65*2.3m

-

Used for:

-

PE PET PVC Plastic Molding

Factory Price Small Injection Molding Machine For PET Product

Injection molding machine is also known as injection molding machine or injection machine. It is the main molding equipment that uses plastic molding dies to make thermoplastic or thermosetting plastics into various shapes of plastic products. The injection molding machine can heat the plastic and apply high pressure to the molten plastic to make it shoot out and fill the mold cavity. An injection molding machine is usually composed of an injection system, a clamping system, a hydraulic transmission system, an electrical control system, a lubrication system, a heating and cooling system, and a safety monitoring system.

Final Products

Preform

Caps

Product Details

T-slot platen and Compulsory ejector return

T-slot platen can increases the overall rigidity of clamping unit by 30%, brings convenience for installation and removal of mold,

reduces the wear of thread due to long-term use of screw hole and extends the life of platen.The compulsory ejector return meets

the requirement of special mold reset and the molds are more applicable.

reduces the wear of thread due to long-term use of screw hole and extends the life of platen.The compulsory ejector return meets

the requirement of special mold reset and the molds are more applicable.

Anti-tilt platen support design

Special anti-tilt platen support design increases the smoothness of motion, lowers friction, improves the efficiency of motion,

reduces energy consumption and prevents the platen from tilting so as to protect the mold.

reduces energy consumption and prevents the platen from tilting so as to protect the mold.

Closed-loop control of mold open position

The enhanced accuracy and repeatability of mold open position result in accurate part removal by robot and benefit automated

continuous production. The mold open position accuracy is smaller than 2mm and repeatability is below 0.3mm.

continuous production. The mold open position accuracy is smaller than 2mm and repeatability is below 0.3mm.

Low pressure mold protection

Low-pressure mold protection control unit ensures the mold gets effectively protected.

Integrated linear guide rail structure

The injection unit is equipped with the one-piece supporting base which is integrated with linear guide rails, which minimizes the

friction to motion, increases injection accuracy and enhances plasticizing efficiency.

friction to motion, increases injection accuracy and enhances plasticizing efficiency.

New universal screw and barrel unit

The upgraded screw and barrel unit further optimizes color mixing and plasticizing efficiency. It has the advantages of easy color

change and cleaning, low shear without temperature rise and wider applicability, etc.

change and cleaning, low shear without temperature rise and wider applicability, etc.

Cap mold

Preform mold

Jar preform mold

Hopper dryer

Chiller-air

Auto Loader

Crusher

Air Compressor

Movable hopper rails

Control System

|

Technical Data for KMK-1700A Injection molding machine

|

|

|

||

|

Screw diameter

|

mm

|

50

|

||

|

Theoretical Shot weight

|

CM3

|

442

|

||

|

Shot weight

|

gram

|

402

|

||

|

Max Injection pressure

|

kg/cm2

|

1960

|

||

|

Theoretical Injection rate (PS)

|

CM3/sec

|

196

|

||

|

Plasticizing capacity

|

g/s

|

26

|

||

|

Screw stroke

|

mm

|

225

|

||

|

Screw torque

|

N.m

|

1310

|

||

|

Screw speed

|

rpm

|

250

|

||

|

Heating power

|

kw

|

13.6

|

||

|

Clamping force

|

ton

|

170

|

||

|

Opening stroke

|

mm

|

460

|

||

|

Mould height

|

mm

|

180~500

|

||

|

Space between tie bars

|

mm

|

480×480

|

||

|

Ejector force/stroke

|

ton/mm

|

4.52/115

|

||

|

Oil pump motor

|

kw

|

15

|

||

|

Machine size

|

m

|

5.2X1.3X2

|

||

|

Packing size

|

m

|

5.62×1.48×2.23

|

||

|

Machine weight

|

ton

|

5

|

||

Successful Production Video

Why Choose Us

Zhangjiagang Comark Packaging Machinery Co.,ltd

Zhangjiagang Comark Packaging Machinery Co., Ltd. is located in Zhangjiagang Economic Development Zone on the Bank of the Yangtze River. It has an international

standard plant of 20000 square meters

. It is an enterprise specializing in the R & D and production of beverage packaging machinery.Our team has more than 20 professional technical R & D personnel,

2 doctors

of food science and technology,

5

masters and

15

senior professional engineers. This provides a favorable guarantee for the stable operation of the machine with high output. Our company's equipment is of high quality and can operate stably.We have more than

15 years

of packaging experience. We understand market supply and demand and can provide market analysis, project budget, equipment and technology configuration,

machines installation

and operator training, etc. We always provide

turnkey solutions

and related services.

FAQ

Q:How to find COMARK Machinery?

A:

Search Alibaba, Made in China, Google, Youtube and find suppliers and manufacturer and not traders

Visit exhibition in different countries

Send Comark Machine an request and tell your basic inquiry

Comark Machine sales manager will reply you in short time and add instant chatting tool

Q:If we purchase machines, what can you provide for us?

A1: We can provide whole solutions.We have professional engineer who analysis production demand based on customer market demand and customer budget .

Q:What's your guarantee or the warranty of the quality if we buy your machines?

A: We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Visit exhibition in different countries

Send Comark Machine an request and tell your basic inquiry

Comark Machine sales manager will reply you in short time and add instant chatting tool

Q:If we purchase machines, what can you provide for us?

A1: We can provide whole solutions.We have professional engineer who analysis production demand based on customer market demand and customer budget .

A2:

We have the bottle shape design according to customer inquire. We also can provide the machines layout for you according your factory figure plan.

A3:

We will send our professional engineer to your factory as soon as you get all your machines ready, for installation, testing and teaching your technicians how to run the machines.

Q:Do you have any reference project?

A: We have reference project in most countries, and you can visit their factories if we get the permission of the customer. And we have made video of every machine and uploaded them to Youtube.I can share with you.

Q:When can I get my machine after I paid?

A: We will deliver the machines on time as the date we agreed both side. Normally production time is around 35-75 days. The exact time depends on what kinds of machine you ordered. The shipping time is based on your destination port.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you. You can come to China.Check it!

Q:Do you have any reference project?

A: We have reference project in most countries, and you can visit their factories if we get the permission of the customer. And we have made video of every machine and uploaded them to Youtube.I can share with you.

Q:When can I get my machine after I paid?

A: We will deliver the machines on time as the date we agreed both side. Normally production time is around 35-75 days. The exact time depends on what kinds of machine you ordered. The shipping time is based on your destination port.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you. You can come to China.Check it!

Q:What's your guarantee or the warranty of the quality if we buy your machines?

A: We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Hot Searches