- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customize

-

Weight (KG):

-

8500

-

Raw material:

-

Coconut Shell,Sawdust, Bagasse, Olive Pomace, Rice Husk, Palm Shell

-

Final product:

-

Charcoal,biochar

-

Final product usage:

-

Make Charcoal Briquettes

-

Color:

-

Customer's Request

-

Carbonization time:

-

2 hour

-

Instalation:

-

Engineer Guide

Quick Details

-

Place of Origin:

-

Henan, China

-

Effective Volume:

-

15CBM

-

Dimension(L*W*H):

-

8*2*2

-

Voltage:

-

Customize

-

Weight (KG):

-

8500

-

Raw material:

-

Coconut Shell,Sawdust, Bagasse, Olive Pomace, Rice Husk, Palm Shell

-

Final product:

-

Charcoal,biochar

-

Final product usage:

-

Make Charcoal Briquettes

-

Color:

-

Customer's Request

-

Carbonization time:

-

2 hour

-

Instalation:

-

Engineer Guide

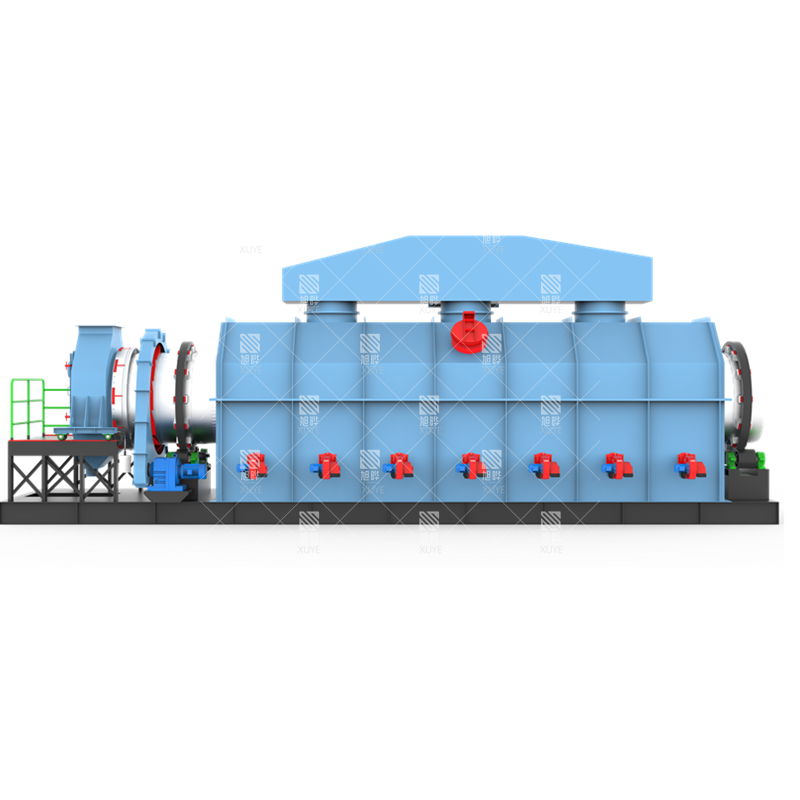

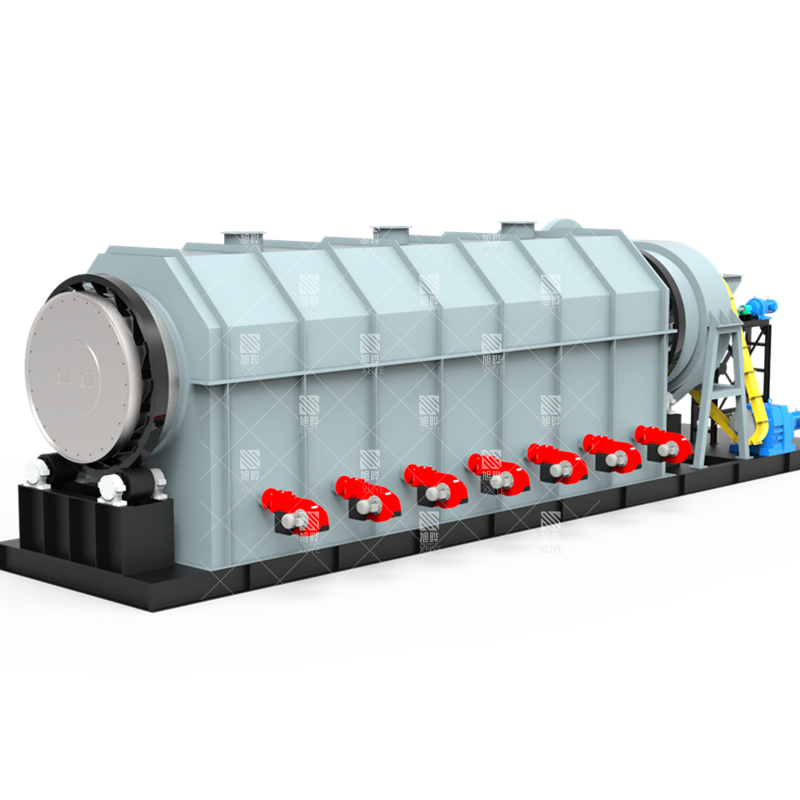

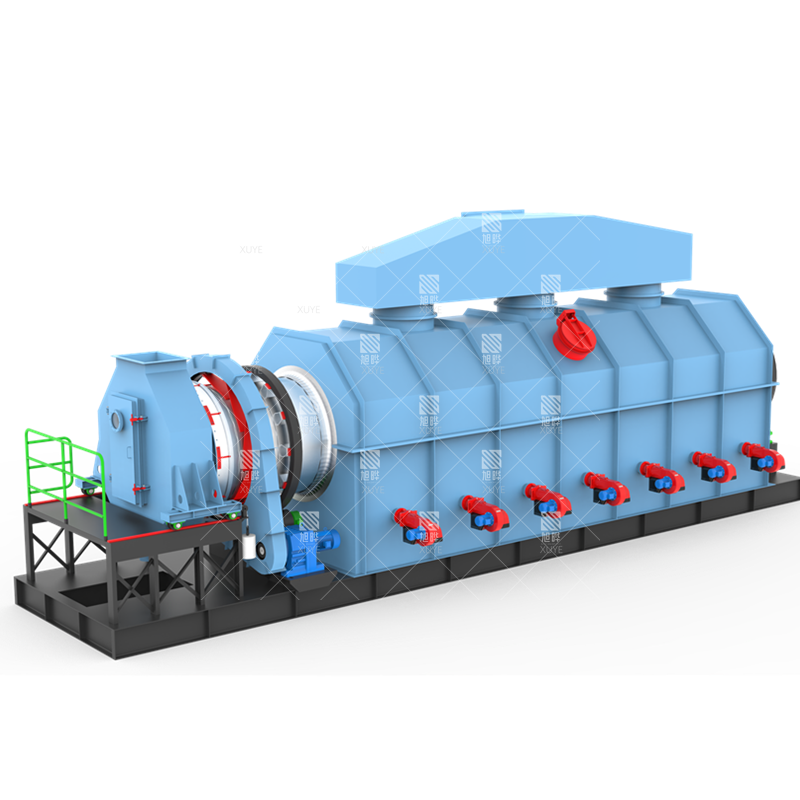

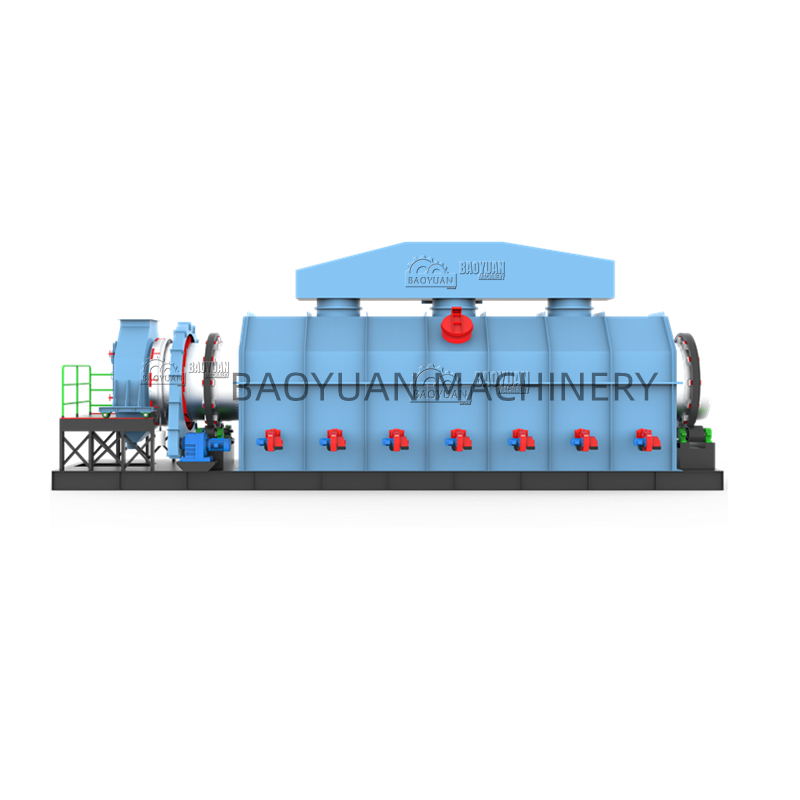

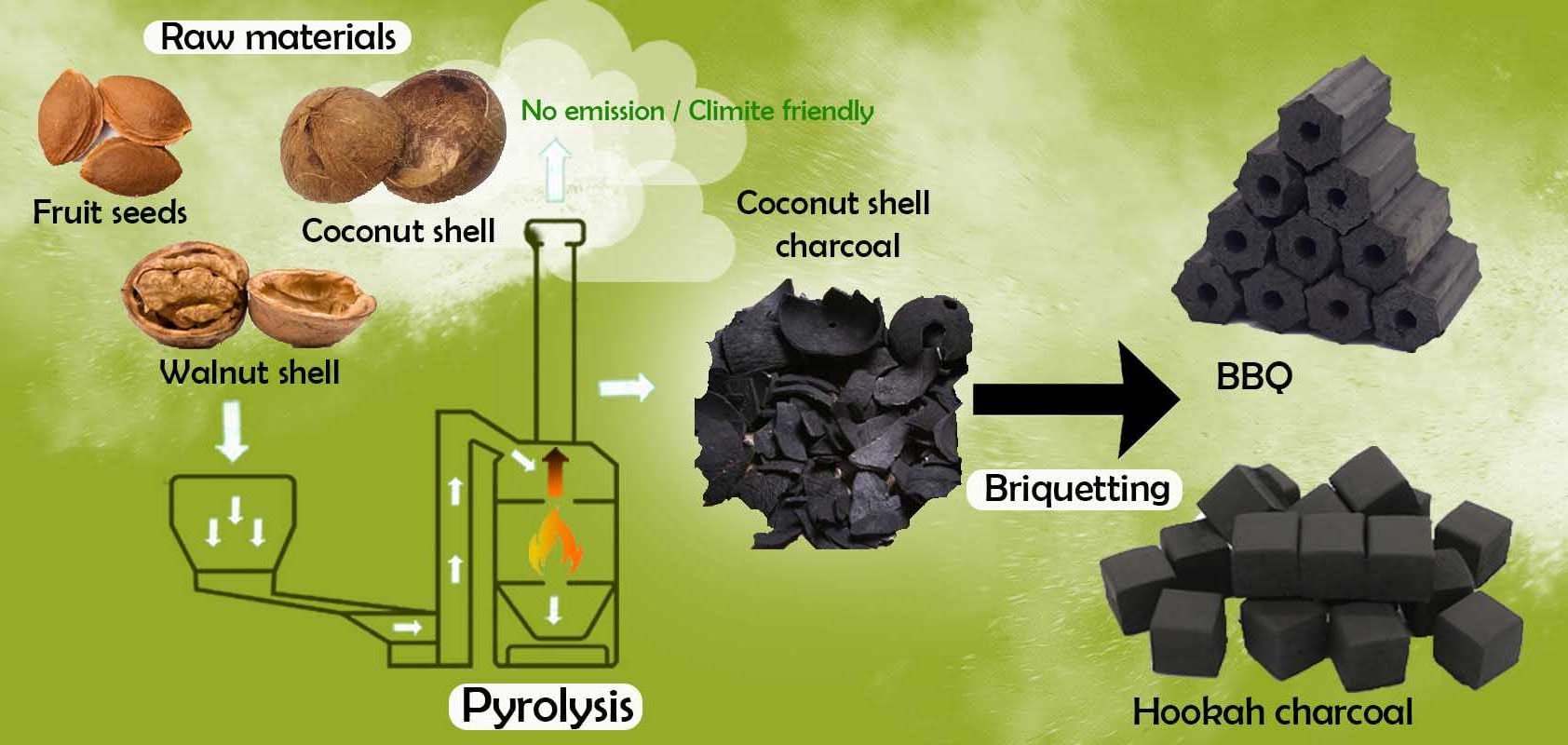

Products Description

Biomass Pyrolysis Equipment Continuous Carbonization Furnace for Sawdust, Coconut Shell, Bagasse, Olive Pomace, Rice Husk, Palm

>Feed waste coconut shells into the reactor.

>

Preheat the main oven for 60-90 minutes.

>

The temperature in the furnace gradually rises, and the reaction gradually begins. Coconut shell charcoal, tar, wood vinegar, and bio-gas are constantly being extracted. The temperature in the furnace can reach 600-850 degrees Celsius. The pyrolysis of coconut shells only takes about 15-25 minutes.he biochar can be directly discharged by the water-cooled slag discharge system.Wood combustible gas can be reused as heat source

>

Exhaust gas meets emission standards after being treated by a spray tower and demisting tower.

Technical Parameters

|

Equipment model classification

|

THJ-Ⅰ

|

LXTHJ-Ⅱ

|

LXTHJ-Ⅲ

|

|

Pipe diameter (mm)

|

Ø800*1200

|

Ø1000*1600

|

Ø1200*2000

|

|

Equipment output (kg/h)

|

400-500

|

600-800

|

800-1000

|

|

Fan power (kw) frequency conversion speed regulation

|

7.5

|

11

|

15

|

|

Continuous carbonization machine main engine power (kw) speed regulation

|

4

|

5.5

|

7.5

|

|

Cooling charcoal machine motor power (kw)

|

3

|

3

|

3

|

|

Screw feeder motor power (kw)

|

3

|

3

|

3

|

|

Burner(s)

|

1

|

1

|

2

|

|

Liquefied gas burner (pcs)

|

8

|

8

|

8

|

|

Auxiliary burner (pcs)

|

1

|

1

|

1

|

|

Working temperature of high temperature carbonization pipeline (℃)

|

500-800

|

500-800

|

500-800

|

|

Furnace temperature (℃)

|

350-800

|

350-800

|

350-800

|

Biomass Pyrolysis Equipment Continuous Carbonization Furnace for Sawdust, Coconut Shell, Bagasse, Olive Pomace, Rice Husk, Palm

,

Charcoal is a macroporous high-carbon product obtained by sub-stoichiometric heating of wood beyond atmospheric ignition temperature. The structure and properties of charcoal are determined by the time/temperature regime of pyrolysis. Industrial charcoal is obtained at a final pyrolysis temperature of 450-550 °C.

Pyrolysis of wood (dry distillation of wood) – decomposition of wood when heated without access to air with the formation of gaseous and liquid products and a solid residue – charcoal.

Product Application

Raw materials

seeds;

shells and pits of tree-fruits;

wood chips;

bamboo;

shrubby and other plant materials, the fraction of which is from 5 to 30 mm with a moisture content of not more than 15%.

|

Coconut shell

|

Walnut shell

|

Hazelnut shell

|

Wood chips

|

Bamboo

|

|

Coconut shell charcoal

|

Shell charcoal

walnut

|

Hazelnut shell charcoal

|

Wood chips charcoal

|

Bamboo charcoal

|

|

Palm kernel shell

|

Pits of olives

|

Pits of date

|

Peach Shell

|

Hawthorn Seed

|

|

Palm kernel charcoal

|

Pits of olives charcoal

|

Pits of date charcoal

|

Peach Shell charcoal

|

Hawthorn Seed charcoal

|

Received products

Raw materials for obtaining activated carbon

Raw Material for BBQ Charcoal Briquette and Industry

Raw materials for the production of coal briquettes for hookahs (hookah, hookah coal)

BIO-Char, as a fertilizer or hydroponic growth intended for the agricultural industry, is made from plant raw materials and does not contain harmful substances.

Working principle and process

Brief description of the production process

Biomass Pyrolysis Equipment Continuous Carbonization Furnace for Sawdust, Coconut Shell, Bagasse, Olive Pomace, Rice Husk, Palm,

The machine is equipped with: crushing system, drying system, liquefied gas combustion system, flue gas purifier, fan, self-distributing gas burner, dry distillation carbonization furnace, secondary combustion chamber, grinding system, environmental protection carbon rod production and other equipment ( See attached image for details).

This system is energy-saving, environmentally friendly, dust-free, smoke-free and tasteless. The direct-fired type does not produce wood tar and wood vinegar. It adopts the double-drum dry distillation and carbonization method to make full use of the combustible gases such as carbon monoxide, methane, and hydrogen generated in the carbonization process. The gas purification system separates dust (the dust will enter the cold carbon machine with the cold carbon equipment) and pure combustible gas, and then fully burns through the self-distributing air burner to heat the high temperature carbonization equipment (the temperature is generally controlled at about 700-800 ℃ ). There are double sleeve pipes inside the carbonization machine, the inner barrel is a preheating and drying pipe, and the outer barrel is a high temperature carbonization pipe. The inner cylinder pipe uses the waste heat in the furnace to dry the material, and the outer cylinder is provided with a combustible gas recovery pipe. The combustion of the burner heats the pipeline, and the mixed gas collected from the carbonization equipment enters the filter system from the lower part, and the filtered pure gas is recycled to the combustion chamber heating equipment to achieve the effect of reciprocating cycle heating and carbonization. The primary carbonization ignition gas source is supplied by the liquefied gas combustion system.

Hot Searches