- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Overseas Service Center

-

Product name:

-

Stone Crusher Plant

-

Processed Materials:

-

Various stones, rocks and mining ores

-

The Machines classification:

-

Africa Stone Crusher Production Line

-

Installation:

-

Under Technical Guidance

-

Spare Parts Supply:

-

Anytime

-

COLOR:

-

Customized

-

Capacity:

-

40-500 tph

-

After sale Service:

-

1year

-

Motor:

-

Chinese Famous Brand

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

CFTC

-

Weight:

-

95000 KG

-

After-sales Service Provided:

-

Overseas Service Center

-

Product name:

-

Stone Crusher Plant

-

Processed Materials:

-

Various stones, rocks and mining ores

-

The Machines classification:

-

Africa Stone Crusher Production Line

-

Installation:

-

Under Technical Guidance

-

Spare Parts Supply:

-

Anytime

-

COLOR:

-

Customized

-

Capacity:

-

40-500 tph

-

After sale Service:

-

1year

-

Motor:

-

Chinese Famous Brand

Product Description

Complete set stone crushing line

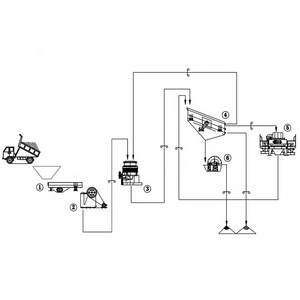

● The whole crushing plant consists of feeding machine, crushing machine, screening machine and conveying system.

● The vibrating feeder feeds the raw material into the jaw crusher steadily and evenly for primary crushing. Discharged from the jaw crusher, the stone materials are directly conveyed into the cone / impact crusher for second crushing.

● All the crushed material came out from jaw crusher will be transported to the cone crusher for the secondary crushing.

● After that, all the material will be transported to a vibrating screen and the material will be separated into different required sizes.

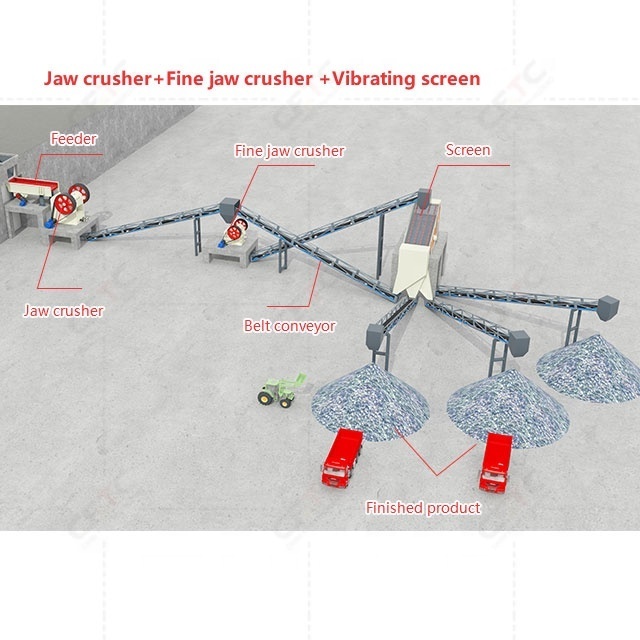

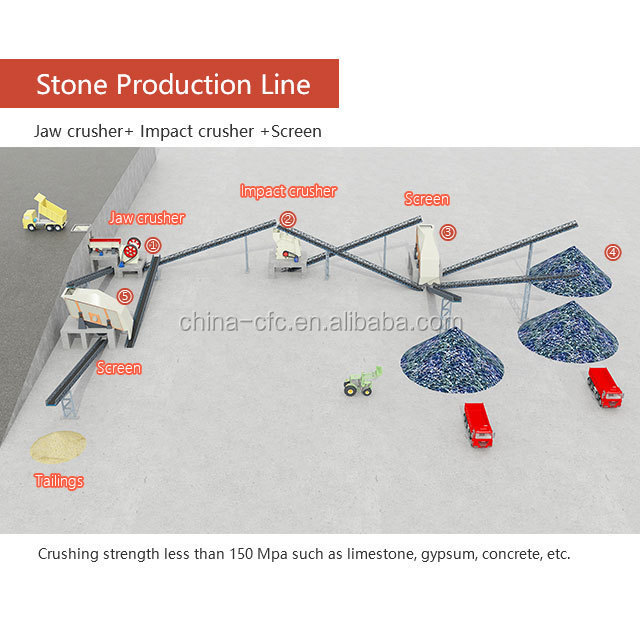

We can provide you different stone crushing solutions as follows according to your raw material and requirement.

|

40-500t/h Hard Stone Crushing Solution

|

|

|

||

|

Equipment

|

Model

|

Function

|

||

|

Feeding Machine

|

GZT or ZSW feeder

|

It can deliver materials to the crusher continuously and uniformly, so it can effectively improve the capacity and continuous working ability of the followed crusher.

|

||

|

Primary Crushing

|

PE series jaw crusher

|

It is capable of breaking any material with compressive strength under 320Mpa and is always used for primary crushing of stones.

|

||

|

Fine Crushing

|

Cone crusher or Impact crusher

|

It is used for fine crushing and its final products is of uniform and cubic granularity, reducing the production load for re-crushing.

|

||

|

Screening Machine

|

YK series vibrating screen

|

It can screening crushed stone materials into required sizes.

|

||

Product packaging

Customer site

Our machine has been sold to Germany, Australia, Japan, Mexico, Philippines, Indonesia, Russia, Uganda, Uzbekistan, Zimbabwe, etc. and our products are well received by customers.

All machine has a 1-year quality assurance. As long as the machine has any problem (non-human factors) within one year, we will repair or change with new one for free. Please rest assured to buy and use!

Welcome your order!

Services

Marketing service staff provides you with one-to-one service to thoroughly solve your problems in equipment purchase, operation cost, production management and after-sales service through professional knowledge and considerate service. It is our management idea to seek maximum benefits for you.

Company Introduction

Located in Zhengzhou, Henan Province of China,

China First Engineering Technology Co., Ltd. (CFTC)

is specialized in research, development, manufacture and sales service of mining equipment. We have the only academician station and researching center of high-quality aggregate in China.

FAQ

1.Quality guarantee

After the machine completed producing, the factory arrange the test practice, to ensure the smooth operation of the machine.

2.Warranty

100% brand new when leaving the factory. The seller guarantee quality of the machines(excluding wearing parts)for a period of one year from the date of trial run finish under our technician's guidance, but not exceed 15 months from date on which machine leaves the factory.

3. Packing

When the goods arrive at the customer site, simply connect power supply to trial production. The products should be processed to be rustproof and moisture proof before delivery. The small parts are packed into wooden crates; the big parts are wrapped by plastic sheeting.

4. Installation

Installer should be familiar with the equipment structure, capacity and technical requirement, set out suitable installation process rules in advance.

Hot Searches