- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

7500

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

2200*500*1200mm

-

Marketing Type:

-

New Product 2023

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

Canada

-

Material:

-

Food Grade Stainless Steel

-

Processing:

-

maize milling machine

-

Capacity:

-

800-1000kg/h

-

Main product:

-

Flour Miller

-

Advantage:

-

High Efficiency Working

-

MOQ:

-

1 Set

-

Package:

-

Standard Wooden Box

-

Usage:

-

Grinding Wheat Maize Corn Rice

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TD

-

Production Capacity:

-

800-1000kg/h

-

Voltage:

-

380V

-

Power:

-

7500

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

2200*500*1200mm

-

Marketing Type:

-

New Product 2023

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

Canada

-

Material:

-

Food Grade Stainless Steel

-

Processing:

-

maize milling machine

-

Capacity:

-

800-1000kg/h

-

Main product:

-

Flour Miller

-

Advantage:

-

High Efficiency Working

-

MOQ:

-

1 Set

-

Package:

-

Standard Wooden Box

-

Usage:

-

Grinding Wheat Maize Corn Rice

video

Technical Parameters

|

Model:

|

DVM-3B

|

|

Motor:

|

7.5kw

|

|

Capacity:

|

800-1000kg/h

|

|

Power:

|

380V

|

|

Weight:

|

300kg

|

|

Dimension'

|

2200*500*1200mm

|

Products Description

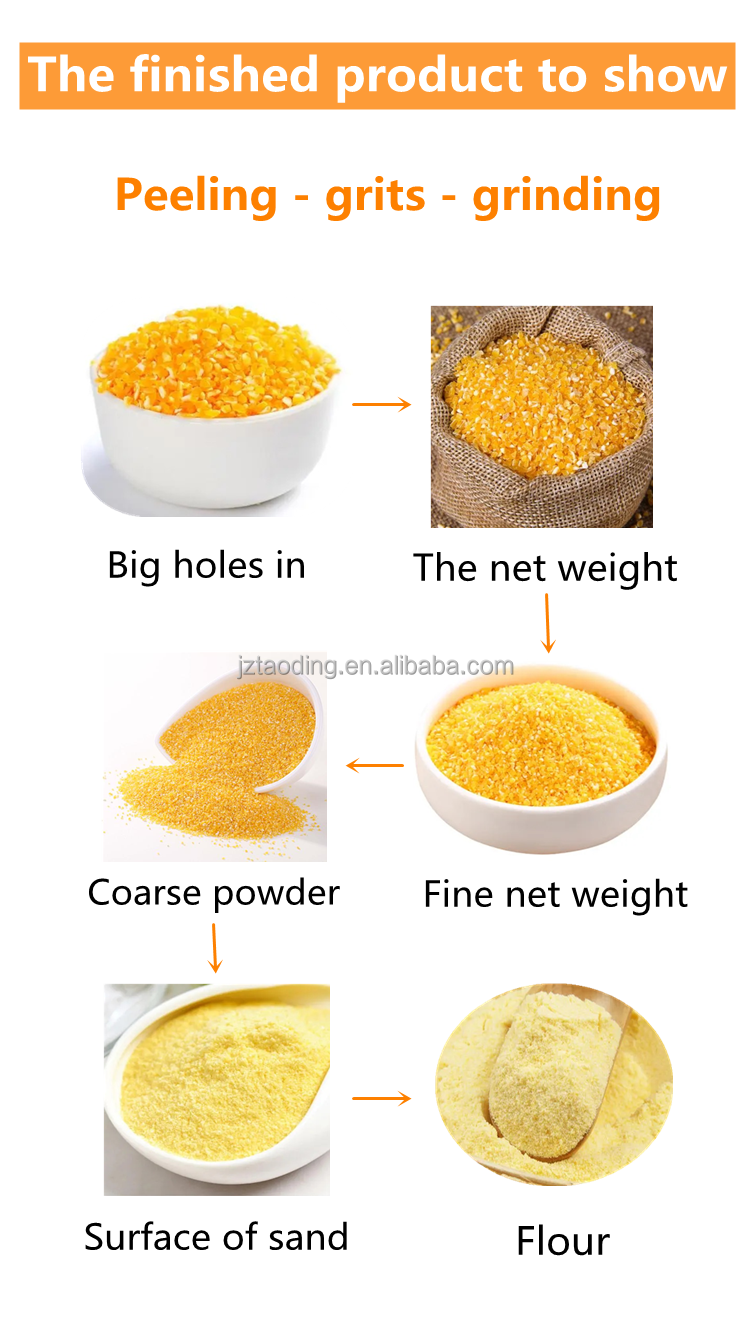

1. Multi-energy and high-efficiency grain processing machine is a small combined corn processing equipment that integrates corn peeling and polishing, grits making, flour milling, finished product grading and winnowing.

2. Put the clean raw grains into the feed inlet, carry out peeling, degerming, and black star removal. The corn is peeled into corn kernels at a time, then crushed and the crushed mixture is classified, fi

nally three finished products are separated.

3. The machine has a built-in high-efficiency suction chamber to remove the skin and impurities during the peeling process.

Advantages:

1.Professional equipment for corn peeling and determining, adopting advanced design concepts to ensure low crushing rate,complete particles and a high yield.

2.Use the built-in motor technology to save installation space.

3.High-strength spindle and wear-resistant sand roller ensure continuous service life.

4.Two-way air inlet to the main shaft, air suction at the discharge port, reducing the temperature of the finished material and multistage cleaning of the material.

5. Large and smooth discharge port.

6. The motor has large power and high working efficiency.

3.High-strength spindle and wear-resistant sand roller ensure continuous service life.

4.Two-way air inlet to the main shaft, air suction at the discharge port, reducing the temperature of the finished material and multistage cleaning of the material.

5. Large and smooth discharge port.

6. The motor has large power and high working efficiency.

Product Photos

Product Function

Packaging & Shipping

Contact With Me

Hot Searches