- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

Hunan Zhongda

-

Model Number:

-

MAH

-

Place of Origin:

-

Hunan, China

-

Horsepower:

-

10hp-800hp/As customer request

-

Power Source:

-

Electric / diesel

-

Cable Length:

-

/

-

Outlet Size:

-

1inch-18inch/As customer request

-

Power:

-

15-600kW/As customer request

-

motor:

-

As customer request

-

Medium:

-

Sand, Mud, Slurry

-

Material:

-

High Chrome Alloy/Rubber/A05/Cr27/Stainless steel/Cast iron

-

Particle size:

-

Max.104mm

-

Connection:

-

Direct Coupling/Belt Driven/Gearbox

-

Color:

-

As customer request

-

Transport Package:

-

Plywood Case

-

Certification:

-

CE / ISO45001:2018 / ISO9001:2015 / ISO14001:2015

-

Usage:

-

Mine dewatering/slag removal/Cement Plants

-

Lubrication:

-

Oil or Grease

-

Impeller:

-

A05/R55/ceramics

Quick Details

-

Application:

-

Machining, Metal and Equipment Manufacturers, Mining industry, Washing and Cleaning

-

Pressure:

-

As customer request

-

Voltage:

-

220V/230V/380V/400V/415V/460V/1000V

-

Warranty:

-

1 year

-

Brand Name:

-

Hunan Zhongda

-

Model Number:

-

MAH

-

Place of Origin:

-

Hunan, China

-

Horsepower:

-

10hp-800hp/As customer request

-

Power Source:

-

Electric / diesel

-

Cable Length:

-

/

-

Outlet Size:

-

1inch-18inch/As customer request

-

Power:

-

15-600kW/As customer request

-

motor:

-

As customer request

-

Medium:

-

Sand, Mud, Slurry

-

Material:

-

High Chrome Alloy/Rubber/A05/Cr27/Stainless steel/Cast iron

-

Particle size:

-

Max.104mm

-

Connection:

-

Direct Coupling/Belt Driven/Gearbox

-

Color:

-

As customer request

-

Transport Package:

-

Plywood Case

-

Certification:

-

CE / ISO45001:2018 / ISO9001:2015 / ISO14001:2015

-

Usage:

-

Mine dewatering/slag removal/Cement Plants

-

Lubrication:

-

Oil or Grease

-

Impeller:

-

A05/R55/ceramics

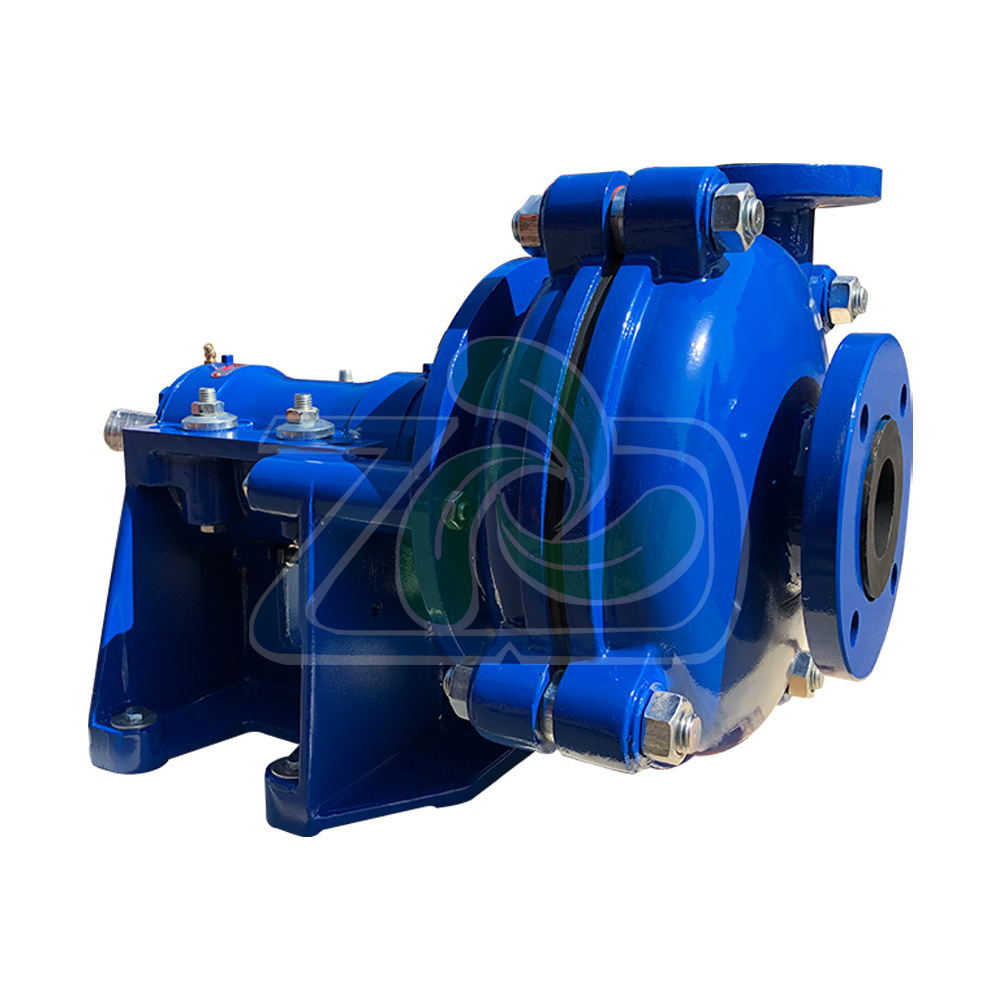

Products Description

The

MAH

series Mineral Processing Heavy Duty Centrifugal Slurry Pump is

designed for the continuous pumping of highly abrasive,high density slurries with minimal maintenance requirements.

The MAH series slurry pump will maintain high efficiencies over the wear life of its components.

Details Images

Application

Product parameter

|

Type

|

Max. power

|

Capacity

|

Head

|

Speed

|

Max.Eff

|

NPSH

|

Impeller Dia.

|

Max.particle size

|

|

|

(kw)

|

(m³/h)

|

(m)

|

(r/min)

|

(%)

|

(m)

|

(mm)

|

(mm)

|

|

MAH1.5-1

|

15

|

12-28

|

6-65

|

1200-3800

|

40

|

2-4

|

150

|

14

|

|

MAH2-1.5

|

15

|

32-72

|

6-58

|

1200-3200

|

45

|

3.5-8

|

185

|

19

|

|

MAH3-2

|

30

|

39-86

|

12-64

|

1300-2700

|

55

|

4-6

|

215

|

25

|

|

MAH4-3

|

60

|

86-198

|

9-52

|

1000-2200

|

71

|

4-5

|

245

|

28

|

|

MAH6-4

|

120

|

162-360

|

12-56

|

800-1500

|

68

|

5-8

|

365

|

44

|

|

MAH8-6

|

120

|

360-830

|

10-61

|

500-1140

|

72

|

2-9

|

510

|

63

|

|

MAH10-8

|

260

|

612-1368

|

11-61

|

400-850

|

71

|

4-10

|

685

|

76

|

|

MAH12-10

|

560

|

936-1980

|

7-68

|

400-750

|

82

|

1-5

|

760

|

86

|

|

MAH14-12

|

560

|

1260-2772

|

13-63

|

300-600

|

77

|

3-10

|

965

|

90

|

|

Rubber Pumps Material

|

|

|

Metal Pumps Material

|

|

|

||||

|

No

|

Part

|

Material

|

No

|

Part

|

Material

|

||||

|

1

|

Base

|

Cast Iron

|

1

|

Base

|

Cast Iron

|

||||

|

2

|

Shaft

|

4140 High Tensile Steel*

|

2

|

Shaft

|

4140 High Tensile Steel*

|

||||

|

3

|

Bearing Assembly

|

Timken (Cast Iron Body)

|

3

|

Bearing Assembly

|

Timken (Cast Iron Body)

|

||||

|

4

|

Shaft Sleeve

|

420 Stainless Steel

|

4

|

Shaft Sleeve

|

420 Stainless Steel

|

||||

|

5

|

Pump Casing

|

Cast Iron

|

5

|

Pump Casing

|

Cast Iron

|

||||

|

6

|

Frame Plate Liner Insert

|

Rubber

|

6

|

Frame Plate Liner

|

27% Chrome White Iron

|

||||

|

7

|

Cover Plate Liner

|

Rubber

|

7

|

Volute Liner

|

27% Chrome White Iron

|

||||

|

8

|

Impeller

|

Rubber Coated High Tensile Steel

|

8

|

Impeller

|

27% Chrome White Iron

|

||||

|

9

|

Throat Bush

|

Rubber

|

9

|

Throat Bush

|

27% Chrome White Iron

|

||||

|

10

|

Cover Plate

|

Cast Iron

|

10

|

Joint Rings

|

Rubber

|

||||

|

11

|

Stuffing Box

|

Cast Iron

|

11

|

Cover Plate

|

Cast Iron

|

||||

|

12

|

Expeller

|

27% Chrome White Iron

|

12

|

Stuffing Box

|

Cast Iron

|

||||

|

13

|

Expeller Ring

|

Natural Rubber

|

13

|

Expeller

|

27% Chrome White Iron

|

||||

|

14

|

Bolts

|

Zinc Plated Steel

|

14

|

Expeller Ring

|

Natural Rubber

|

||||

|

15

|

O-rings

|

Nitrile Rubber

|

15

|

Bolts

|

Zinc Plated Steel

|

||||

|

16

|

Seals

|

Rubber

|

16

|

O-rings

|

Nitrile Rubber

|

||||

|

17

|

Seals

|

Rubber

|

17

|

Seals

|

Rubber

|

||||

Recommend Products

Hot Searches