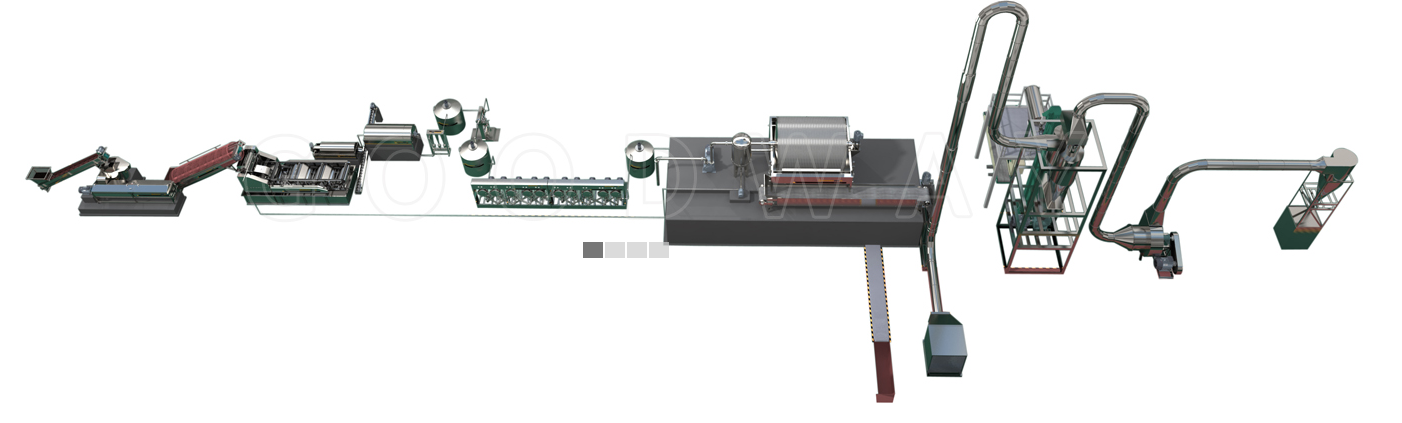

B: we offer custom design of machine connection and factory layout design for our customer's project.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

7000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V/50&60HZ

-

Key Machines:

-

potato cleaning machine, potato crushing machine, potato starch filtering machine, potato starch drying machine

-

Product name:

-

Potato Starch Making Machine Potato Starch Processing Plant

-

Application:

-

Potato starch processing plant

-

Certification:

-

ISO9001:2015

-

Machine Materials:

-

Carbon / Stainless Steel

-

Power Source:

-

Electrical Power

-

Final products:

-

50-200mesh dry starch powder

-

Advantage:

-

Easy Operation High Efficiency

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Package:

-

Standard package

Quick Details

-

Machinery Capacity:

-

300-2000KG/H

-

Brand Name:

-

GOODWAY

-

Dimension(L*W*H):

-

processing line

-

Weight:

-

7000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V/50&60HZ

-

Key Machines:

-

potato cleaning machine, potato crushing machine, potato starch filtering machine, potato starch drying machine

-

Product name:

-

Potato Starch Making Machine Potato Starch Processing Plant

-

Application:

-

Potato starch processing plant

-

Certification:

-

ISO9001:2015

-

Machine Materials:

-

Carbon / Stainless Steel

-

Power Source:

-

Electrical Power

-

Final products:

-

50-200mesh dry starch powder

-

Advantage:

-

Easy Operation High Efficiency

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Package:

-

Standard package

1000 kg/h Output Potato Starch Making Machine Potato Starch Processing Plant

Product Description

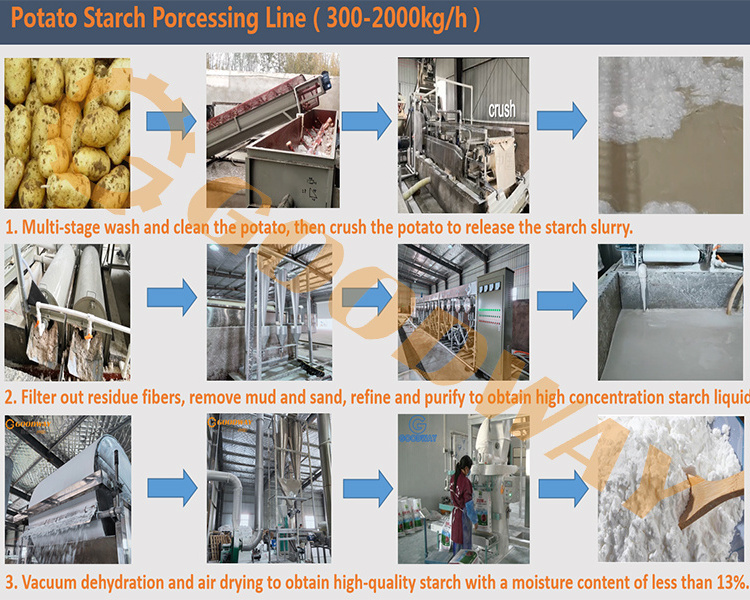

The production of potato starch comprises the machines such as washing machine, crushing machine, fine fiber sieve, de-sanding cyclone and de-silting cyclone, starch hydro cyclone, vacuum filter, airflow flash dryer and packaging machine. We have provided below a brief description on the main steps of the potato starch production process.

|

Product Name

|

Potato Starch Processing Machine

|

|

Machine Material

|

Main Body Carbon /stainless steel

|

|

Cpacity

|

300-2000kg/h

|

|

Standard

|

ISO9001:2015

|

|

Installation

|

100USD per one techinical guy one day

|

|

Service

|

2 year warrenty ,1 year spare parts for free

|

|

Final Product

|

cassava starch

|

Details Images

1. Potato washing machine:

Wash the fresh potato in clean water to remove mud, sand and other impurities.

Note: The water source should be checked regularly to ensure it is not dirty or contaminated.

2. Starch extraction machine:

Crush the potato roots into the cassava slurry, and separate to remove the potato residues, to obtain uniformly smooth starch slurry.

3. Fine fiber sieve

Commonly physical operation which is used for the separation of residues from starch slurry by interposing a medium(filter) through which only the raw starch milk can pass (depending on the pore size and filter thickness).

4. De-sanding and de-silting cyclone:

Solid control equipment that separate sand and silt from the raw starch milk. De-sanding cyclone is installed before the de-silting cyclone and normally the solids diameter for de-sanding cyclone to be separated would be larger than for de-silting cyclone.

5. Starch hydro cyclone:

Classify, separate or sort particles in a liquid suspension based on the ratio of their centripetal force to fluid resistance, this ratio is high for dense and coarse particles, and low for light and fine particles.

6. Vacuum filter:

it's considered a proven technique for separating fines from liquids to realize the starch water content up to 35-40% for the next starch drying.

7. Airflow flash dryer

Effectively dry the wet starch to low moisture content by principle of heat transfer exchange, and sieve to obtain fine granules of uniform size, larger particles of starch that are separated should be broken again.

8. Starch packaging machine:

Pack desired quantities into a woven polythene sack with a plastic lining, seal or stitch the sack to keep the starch clean and fresh during storage.

Installation Instructions

I

nstallation invoice

A: one guy 100USD one day for installation guide.

Our Company

Nanyang Goodway Machinery & Equipment Co., Ltd.

is a leading manufacturer and supplier of Cassava & Potato Processing Machineries since 1991, focus on providing the system solutions in the fields of Cassava Processing Machine, Cassava Starch Processing Machine, Potato Starch Making Machine, Sweet Potato Starch Making Machine, and Cassava Flour Making Machine, Yam Flour Processing Machine, Garri Processing Machinery, Fufu Processing Machine, Cassava Chips Making Machine.

Our Service

Case & Project

FAQ

Q: Are you a factory or trading company?

A: We are factory since 1991.

Q: What is your main product?

A: System solutions in the fields of cassava starch, potato starch, sweet potato starch, cassava and yam flour,garri/gari, fufu flour, cassava chips processing.

Q:How do you control the items quality?

A: Each machine strictly tested one by one before shipping.

Q: How about price?

A: We have our own factory and can give you the competitive price. Besides, we have a policy that " for saving time and absolutely honest business attitude, we quote as low as possible, discount can be given according to quantity".

Q: What is the delivery time?

A:As normal 25-35 days after payment confirmed.

Q: What is the quality guarantee policy?

A:12-24 months guarantee for all goods from our company, but we do not accept any man-made sabotage.

Contact

Hot Searches