- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

250 mm

-

Brand Name:

-

Aoxuanzg, AOXUANZG

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

4000 KG

-

Place of Origin:

-

ANH

-

Voltage:

-

customizable, customizable

-

Year:

-

new

-

Marketing Type:

-

Hot Product 2024

-

Rated Power:

-

7.5

-

Dimension(L*W*H):

-

3040*1710*1620

-

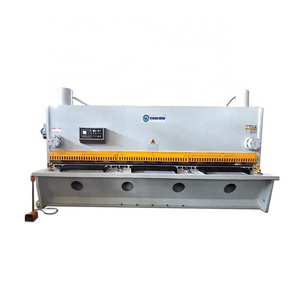

Product name:

-

Hydraulic Shearing Machine

-

Color:

-

customizable

-

Cutting thickness:

-

6mm

-

Stoke times:

-

8 times

-

Motor power:

-

7.5kw

-

Stopper Adjust Range:

-

20-500

Quick Details

-

Max. Cutting Width (mm):

-

3000 mm

-

Max. Cutting Thickness (mm):

-

6 mm

-

Blade Length (mm):

-

3200 mm

-

Throat Depth (mm):

-

250 mm

-

Brand Name:

-

Aoxuanzg, AOXUANZG

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

4000 KG

-

Place of Origin:

-

ANH

-

Voltage:

-

customizable, customizable

-

Year:

-

new

-

Marketing Type:

-

Hot Product 2024

-

Rated Power:

-

7.5

-

Dimension(L*W*H):

-

3040*1710*1620

-

Product name:

-

Hydraulic Shearing Machine

-

Color:

-

customizable

-

Cutting thickness:

-

6mm

-

Stoke times:

-

8 times

-

Motor power:

-

7.5kw

-

Stopper Adjust Range:

-

20-500

Product Description

Hot Sale Metal Steel Cutting Machine Hydraulic Guillotine Swing Beam Shearing with E21S System

Main Features:

1-Special numeric-control system is fitted with mainframe of the bending machine.

2-Multi-work-stop programming function is able to achieve an automatic operation and continues positing of multi-step procedures,

as well as an automatic precision adjustment for positions of rear stopper and gliding block.

3-The machine is provided with bend counting function, for a real-time display of processing quantity and power-failure memory of

positions of stopper and gliding block, as well procedures and parameters.

4-Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear

stopper, for processing precision of machine to be higher.

Standard equipment

Estun E21S CNC control System

Powered Back gaugeX-axis

DELTA Inverter controlled back gauge

HIWIN Ball screws & Polished rod with 0,05mm accuracy

Squaring Arm and Front Support Arms

Germany Bosch-Rexroth Hydraulic

Germany EMB Tubing connector

Germany Siemens Main Motor

Schneider Electrics

Hydraulic &Electrical overload protection

Cutting Line illumination and wire for shadow line cutting

Top blade with four cutting edges and bottom blade with four cutting edges.(6CrW2Si)

1-Special numeric-control system is fitted with mainframe of the bending machine.

2-Multi-work-stop programming function is able to achieve an automatic operation and continues positing of multi-step procedures,

as well as an automatic precision adjustment for positions of rear stopper and gliding block.

3-The machine is provided with bend counting function, for a real-time display of processing quantity and power-failure memory of

positions of stopper and gliding block, as well procedures and parameters.

4-Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear

stopper, for processing precision of machine to be higher.

Standard equipment

Estun E21S CNC control System

Powered Back gaugeX-axis

DELTA Inverter controlled back gauge

HIWIN Ball screws & Polished rod with 0,05mm accuracy

Squaring Arm and Front Support Arms

Germany Bosch-Rexroth Hydraulic

Germany EMB Tubing connector

Germany Siemens Main Motor

Schneider Electrics

Hydraulic &Electrical overload protection

Cutting Line illumination and wire for shadow line cutting

Top blade with four cutting edges and bottom blade with four cutting edges.(6CrW2Si)

Main Configuration

1.ESTUN E21S Control system

2.Backgauge control

3.Controlling common motor or frequency converter

4.Intelligent positioning

5.Double programmable digital output

6.Job count

7.Store 40 programs, 25 steps per program

8.Unilateral positioning

9.Retract function

10.One-click Backup and Recovery of Parameters

11.Metric and British Unit

12.Chinese/English

2.Backgauge control

3.Controlling common motor or frequency converter

4.Intelligent positioning

5.Double programmable digital output

6.Job count

7.Store 40 programs, 25 steps per program

8.Unilateral positioning

9.Retract function

10.One-click Backup and Recovery of Parameters

11.Metric and British Unit

12.Chinese/English

Estun E21s

- Backgauge and block control

- Control for general AC motors,frequen-cy inverter

- Intelligent positioning

- Stock counter

- Holding/decompression time setting

- Program memory of up to 40 programs

- Up to 25 steps per program

- One side positioning

- Retract function

- One key backup/restore of parameters

-mm/inch

- Chinese /English

parameter

Certifications

Packing & Delivery

Packing Detail:

☂ Each Hydraulic Bending Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

✈ We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

Delivery Detail :

☀ Shipped in 25 days after payment

☂ Each Hydraulic Bending Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

✈ We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

Delivery Detail :

☀ Shipped in 25 days after payment

Hot Searches