- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0

-

Density (kg/m³ ):

-

128

-

Length:

-

3600/7200/14640mm

-

Working Temperature:

-

1100

-

Fiber Diameter:

-

2-4mm

-

Shrinkage (1800 ℉, 3h):

-

3%

-

Thermal Conductivity:

-

0.15

-

Model Number:

-

zq0922

-

Brand Name:

-

YT

-

Place of Origin:

-

Shandong, China

-

Name:

-

Ceramic fiber blanket

-

Al2O3:

-

53% - 55%

-

Al2O3 + SiO2:

-

≥99%

-

K2O + Na2O:

-

≤0.2

-

CaO + MgO:

-

≤0.2

-

Dia of Fiber(um):

-

2-4

-

Thickness(mm):

-

10-50

-

Regular Dimension(mm):

-

7200 x 600 x 25 or 3600 x 600 x 50

-

Spec Temperature(℃):

-

1360

-

Working Tempreature(℃):

-

1200

Quick Details

-

Thickness:

-

10-50mm

-

Width:

-

610/1220mm

-

Chemical Composition:

-

Al2O3+SiO2

-

Ultimate Strength (≥ MPa):

-

0

-

Density (kg/m³ ):

-

128

-

Length:

-

3600/7200/14640mm

-

Working Temperature:

-

1100

-

Fiber Diameter:

-

2-4mm

-

Shrinkage (1800 ℉, 3h):

-

3%

-

Thermal Conductivity:

-

0.15

-

Model Number:

-

zq0922

-

Brand Name:

-

YT

-

Place of Origin:

-

Shandong, China

-

Name:

-

Ceramic fiber blanket

-

Al2O3:

-

53% - 55%

-

Al2O3 + SiO2:

-

≥99%

-

K2O + Na2O:

-

≤0.2

-

CaO + MgO:

-

≤0.2

-

Dia of Fiber(um):

-

2-4

-

Thickness(mm):

-

10-50

-

Regular Dimension(mm):

-

7200 x 600 x 25 or 3600 x 600 x 50

-

Spec Temperature(℃):

-

1360

-

Working Tempreature(℃):

-

1200

Products Description

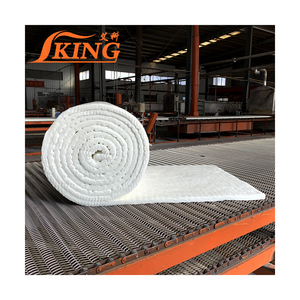

Ceramic Fiber Blanket

Ceramic Fiber Spun Blanket is made of aluminum silicate fiber bulk spinning from kaolin, alumina silicon dioxide and zircon sand,which been series processing of needling ,cutting and rollings,

The blanket is lightweight, flexible ,and available in a wide variety of thickness,widths and densities.

Applications:

Furnace Lining, insulation and repair for kilns, ovens,boilers; Insulation purpose for power plant, thermal reactor, generator,

and nuclear applications;Expansion joint seal and insulation; Wrapping and insulation for high temperature pipe or metal casting

The blanket is lightweight, flexible ,and available in a wide variety of thickness,widths and densities.

Applications:

Furnace Lining, insulation and repair for kilns, ovens,boilers; Insulation purpose for power plant, thermal reactor, generator,

and nuclear applications;Expansion joint seal and insulation; Wrapping and insulation for high temperature pipe or metal casting

Product Paramenters

|

Item

|

STD Grade

|

High Pure Grade

|

High Alumina Grade

|

||

|

Al2O3%

|

45-47

|

47-49

|

53-55

|

||

|

Al2O3+Sio2% (≥)

|

|

98.5

|

99

|

||

|

Fe2O3%≤

|

0.4

|

0.3

|

0.2

|

||

|

K2O+Na2O%(≤)

|

0.3

|

0.2

|

0.2

|

||

|

CaO+Mgo%(≤)

|

0.2

|

0.2

|

0.2

|

||

|

Dia of Fiber(um)

|

2-4

|

2-4

|

2-4

|

||

|

Thickness (mm)

|

6-50

|

6-50

|

10-50

|

||

|

Regular Dimension(mm)

|

7200x600x25 or 3600x600x50

|

|

|

||

|

Spec Temperature(°C)

|

1260

|

1260

|

1360

|

||

|

Working Temperature(°C)

|

1050

|

1100

|

1200

|

||

|

Bulk Density(kg/m3)

|

64,96,128,160

|

|

|

||

|

Permanente Linear Change(24 hours) %(≤)

|

1150°C

|

1250°C

|

1300°C

|

||

|

|

3

|

3.5

|

3.5

|

||

|

Thermal Conductivity (w/m.k)

|

|

|

|

||

|

128kg/m3

|

0.15(800°C)

|

0.15(800°C)

|

0.18(1000°C)

|

||

|

160kg/m3

|

0.14(800°C)

|

0.13(800°C)

|

0.17(1000°C)

|

||

Applications

Tunnel kiln

Square kiln

Shuttle kiln

Ceramic Kiln

Modules flat top kiln

Furnace Lining

Hot Searches