- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220/380

-

Product name:

-

Long-cut pasta production line

-

Material:

-

304/Q235

-

Model:

-

CQ200

-

Capacity:

-

200KG/H

-

Degree of automation:

-

Semi-automatic

-

Plant Design:

-

Free

-

Customization:

-

Support

-

Technical guidance:

-

Provide

Quick Details

-

Machinery Capacity:

-

200KG/H

-

Brand Name:

-

PARMAT

-

Year:

-

2024

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220/380

-

Product name:

-

Long-cut pasta production line

-

Material:

-

304/Q235

-

Model:

-

CQ200

-

Capacity:

-

200KG/H

-

Degree of automation:

-

Semi-automatic

-

Plant Design:

-

Free

-

Customization:

-

Support

-

Technical guidance:

-

Provide

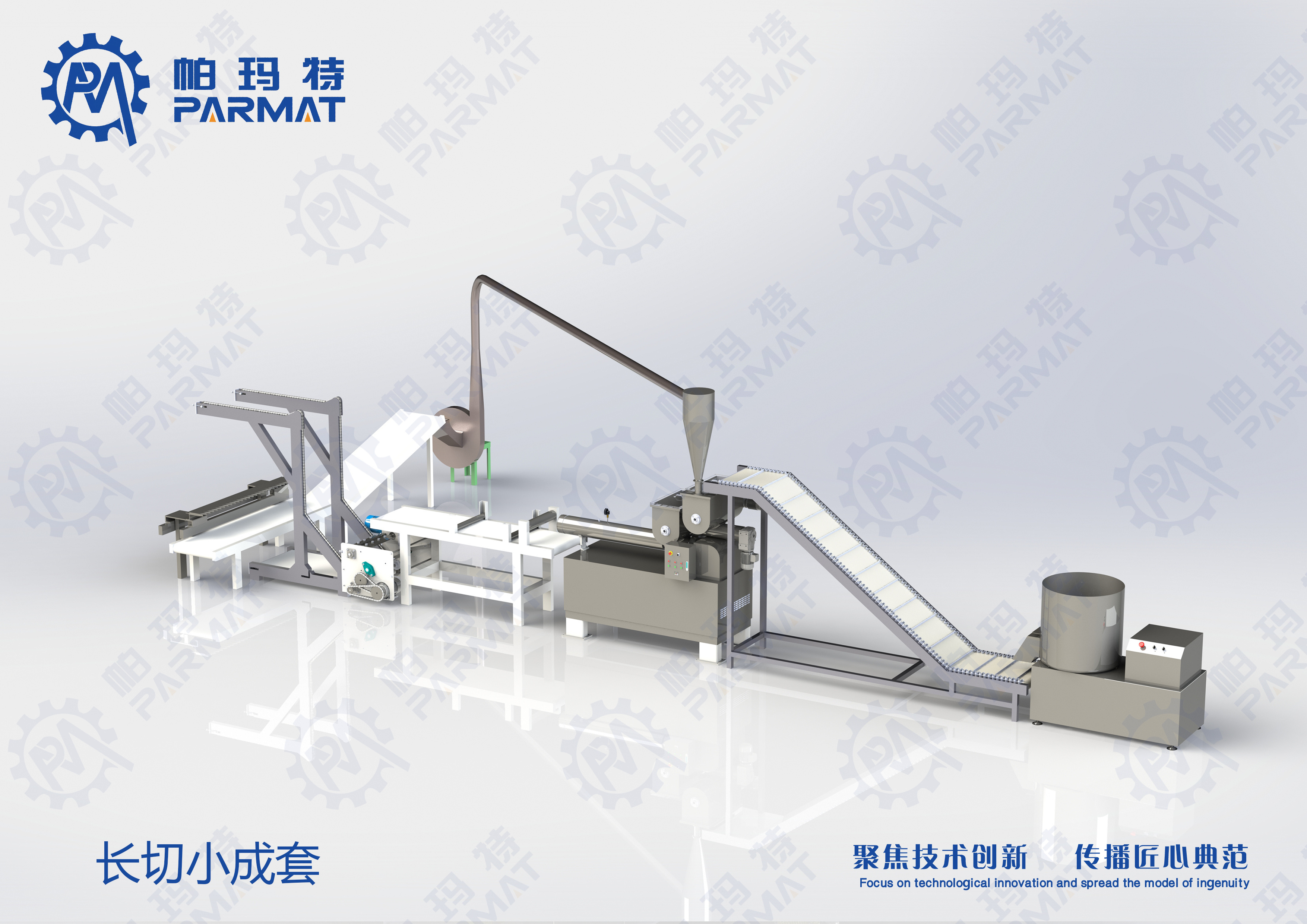

Production Line Description

Throughout our history in pasta production, we have always concentrated on quality and innovation. We have created state-of-the-art processes and breakthrough technologies – all designed to achieve top pasta quality and world-renowned performance.

CQ500 LONG-CUT DRY SPAGHETTI PASTA PRODUCTION LINE

PARMAT Automations is one of the leading developers and manufacturers of industrial equipment for pasta production with a capacity of 50 to 3000 kg/h.

PASTA PRODUCTION LINE MANUFACTURER

Complex automation system equipped pasta production line main purpose is provide high quality product with low investment price. Using latest and newest technology, we can build-up or redesign your facility's manufacture ability to reach high quality product.

CQ200 LONG-CUT DRY SPAGHETTI PASTA PRODUCTION LINE

This production line is executable for long-cut

dry

pasta.

CQ200 LONG-CUT DRY SPAGHETTI PASTA PRODUCTION LINE

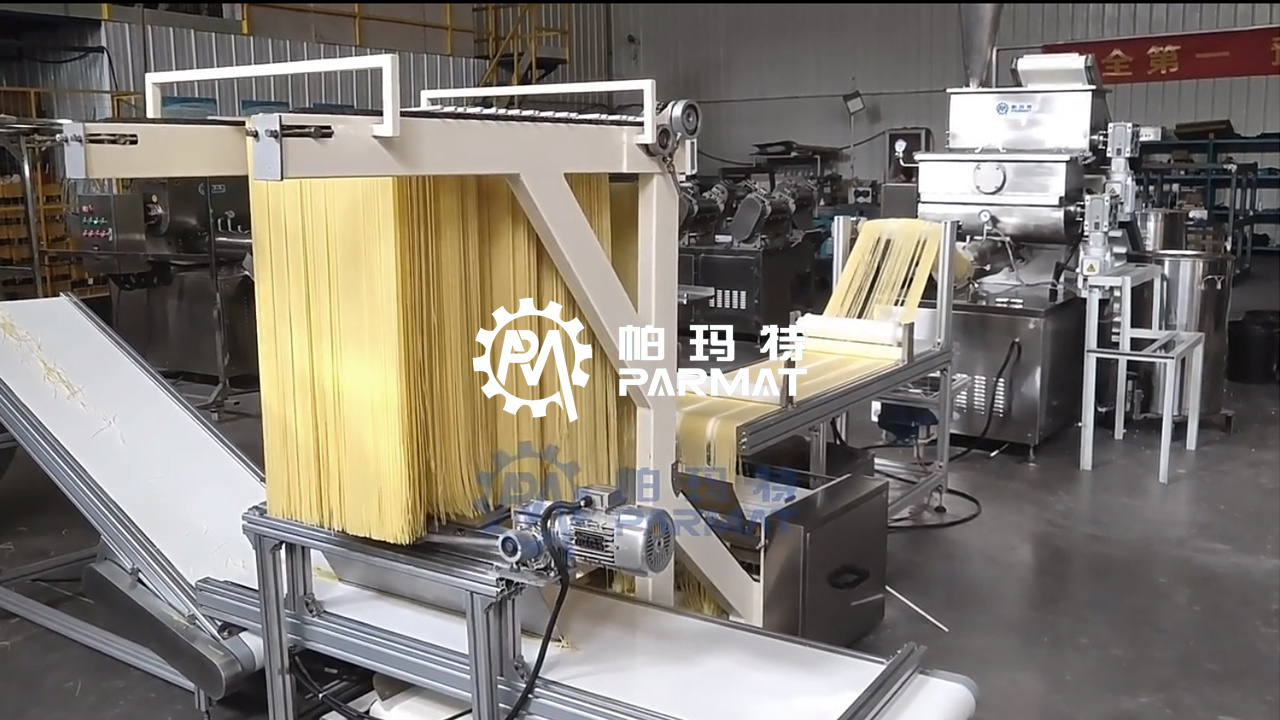

Spreader:

Used to separate spaghetti from leaving, so that they do not stick together.

CQ200 LONG-CUT DRY SPAGHETTI PASTA PRODUCTION LINE

Automatic hanging rod device and shear device, no manual operation, can be set to set the cutting length.

CQ200 LONG-CUT DRY SPAGHETTI PASTA PRODUCTION LINE

The rod device can carry a lot of spaghetti, and they will gradually move backwards and pass the cutting equipment below.

CQ200 LONG-CUT DRY SPAGHETTI PASTA PRODUCTION LINE

Put the spaghetti in a small cart dedicated to the drying room. The upper and lower floors can be placed. It is ready to enter the drying steps of the next stage.

CQ200 LONG-CUT DRY SPAGHETTI PASTA PRODUCTION LINE

Static or continuous dryers: break down the percentage of humidity of the product. The drying process can be done at high o low temperatures, with automatic control of the temperature and humidity.

CQ200 LONG-CUT DRY SPAGHETTI PASTA PRODUCTION LINE

You can interchange according to your needs, by integrating a single machine in your company production or considering the whole and complete line of production. We can serve you a turn-key plant.

They are equipped with a specific ventilation system and humidity exhaust system for long pasta enabling initial pre-drying phase

(eliminating the extra costs for a pre-drying tunnel) and subsequent drying and stabilization, which are automatically managed by the PLC located on the electric control panel.

Static dryer

can accurately control temperature and humidity, and the complex drying process and labor costs solved.

high quality products during the extrusionstage

Production Line Parameters

|

Machine name

|

Configure

|

Power

|

Weight

|

Material

|

Device Description

|

|

CQ200-B

|

CQ200Type high-speed dough mixer

|

5.5KW

|

220KG

|

304/Q235

|

Powder mixer for mixing with water Quick discharge device with pneumatic gate

|

|

Raw material handling section

|

CQ200 Raw material conveyor

|

0.25KW

|

80KG

|

PVC/Aluminum alloy

|

Elevator for conveying raw materials

|

|

CQ200-B host part |

CQ200 Screw feeder

|

1.1KW

|

680KG |

304

|

|

|

|

CQ200 vacuum mixer

|

1.5W

|

|

304

|

Mixer that can be mixed under vacuum or under normal pressure

|

|

|

CQ200 type vacuum extruder

|

11KW

|

|

304

|

Extruder with water-cooled jacket

|

|

|

CQ200 die

|

|

|

304

|

Can be used for the production of various shaped products by means of quick-change die

|

|

|

CQ200 Electronic control system

|

45A

|

|

304/Q235

|

|

|

|

CQ200 vacuum system

|

0.55KW

|

|

304/Q235

|

Small vacuum unit with automatic inflation and decompression

|

|

|

CQ200 water cooling device

|

0.18KW

|

|

304/Q235

|

Cooling for extruders

|

|

|

CQ200Filament

|

0.49KW

|

70KG

|

Aluminum

|

Material conveying

|

|

CQ200-B type auxiliary equipment

|

conveyor

|

|

|

Alloy/PVC

|

Equipment PVC material, aluminum alloy frame

|

|

|

CQ200 Back-up machine

|

0.4KW

|

180KG |

Q235

|

Equipment for spaghetti hanging rod conveying

|

|

|

CQ200 Cutting machine

|

0.75KW

|

|

304

|

Fixed length cutting machine

|

|

|

CQ200 Shearing machine

|

0.25KW

|

120KG |

304/Q235

|

Equipment for cutting spaghetti

|

|

|

CQ200 Type Crushing Conveyor

|

0.18KW

|

|

Aluminum alloy/PVC

|

The chopped head conveyor after trimming

|

|

|

CQ200 Type pneumatic crushing conveyor

|

2.2KW

|

60KG

|

304

|

After crushing and shearing, the crushed heads are conveyed to the mixer by pneumatic force for reuse

|

|

|

CQ200 Type unloading device

|

|

50KG

|

304

|

Component discharge device

|

|

|

Hanging rod

|

(give away200)

|

5.4KG0.76USD/root

|

PVC

|

For holding products

standard hanger |

|

|

Trolley

|

(give away 1tower400/tower

|

20KG

|

304

|

Trolley for holding the hanging rod

|

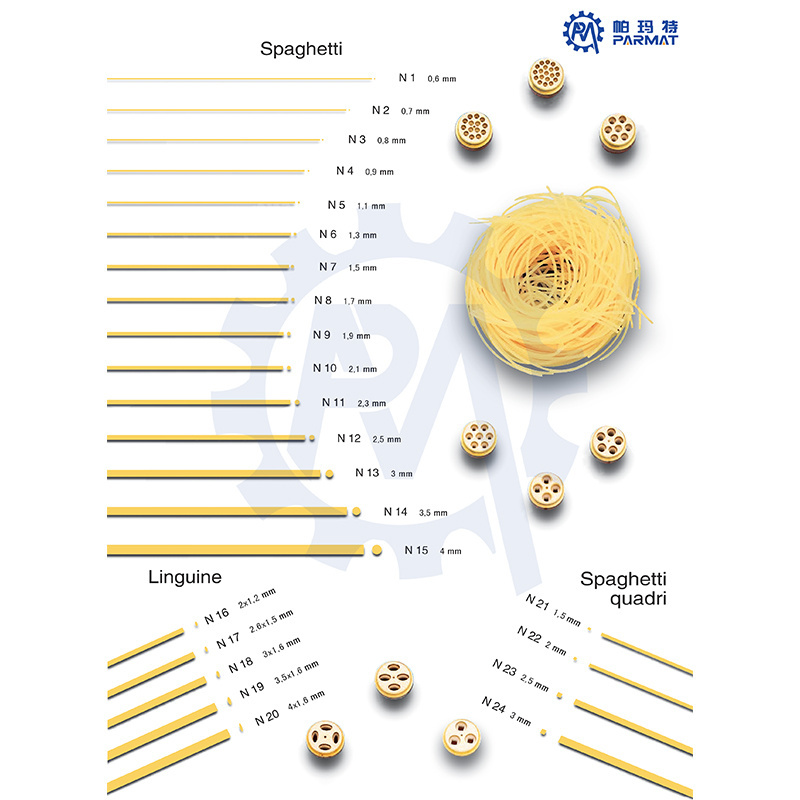

Different Specifications of Pasta

Exhibition

Our pasta machines and production lines are sold to multiple countries to produce delicious pasta foods to bring good investment returns to customers. Our core technology, quality and after -sales are trusted.

Customer Photos

Project Installation

Certifications

24-Hour Service

Hot Searches