- Product Details

- {{item.text}}

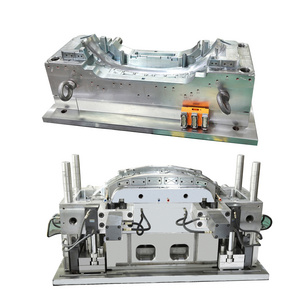

Quick Details

-

Model Number:

-

TS-IE-1153

-

Product Name:

-

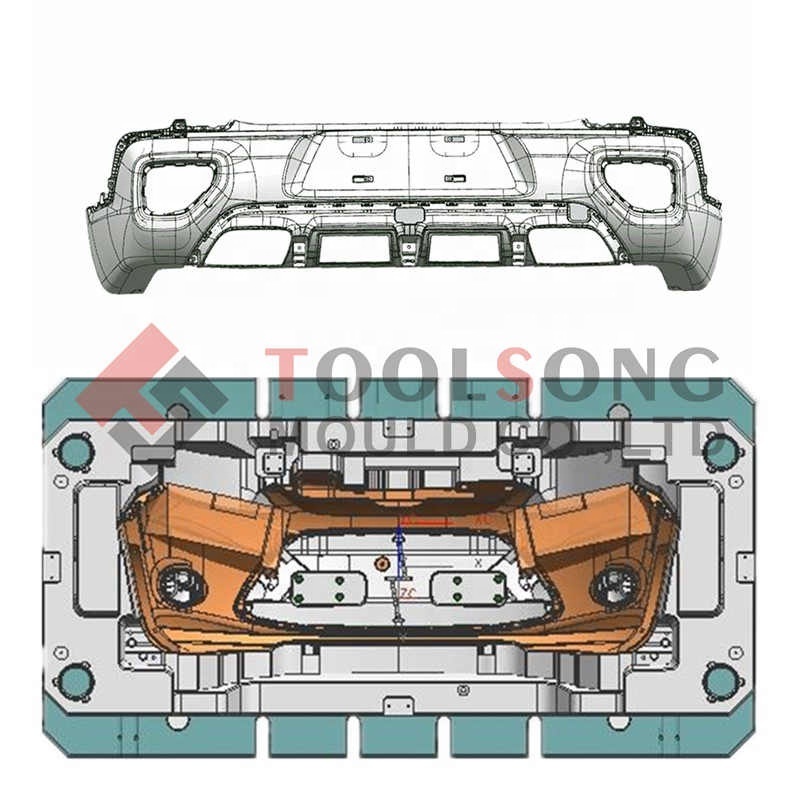

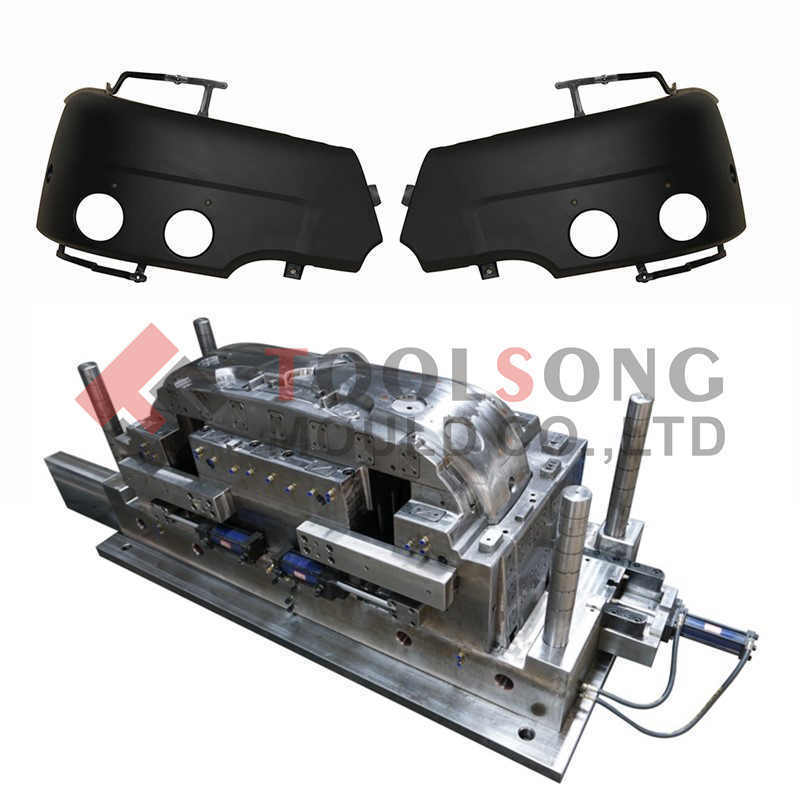

ODM Plastic Car Bumper Production Line In Taizhou

-

Application:

-

Plastic Injection Mould Making

-

Cavity:

-

1

-

Runner:

-

YUDO hot runner

-

Gate type:

-

open gate

-

Mould life:

-

300000-1000000shots

-

Mold material:

-

1.2738H, 718HH, P20, etc

-

Mold Base:

-

S50C, 1.1730, 1.2311, 45#

-

Standard:

-

LKM, HASCO, DME or upon customer's requirement

-

Design software:

-

PROE, UG, CAD

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Toolsong

-

Model Number:

-

TS-IE-1153

-

Product Name:

-

ODM Plastic Car Bumper Production Line In Taizhou

-

Application:

-

Plastic Injection Mould Making

-

Cavity:

-

1

-

Runner:

-

YUDO hot runner

-

Gate type:

-

open gate

-

Mould life:

-

300000-1000000shots

-

Mold material:

-

1.2738H, 718HH, P20, etc

-

Mold Base:

-

S50C, 1.1730, 1.2311, 45#

-

Standard:

-

LKM, HASCO, DME or upon customer's requirement

-

Design software:

-

PROE, UG, CAD

|

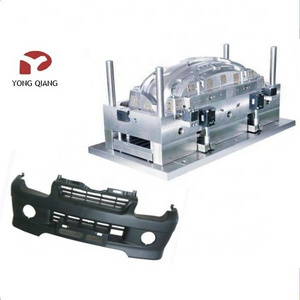

Product Name

|

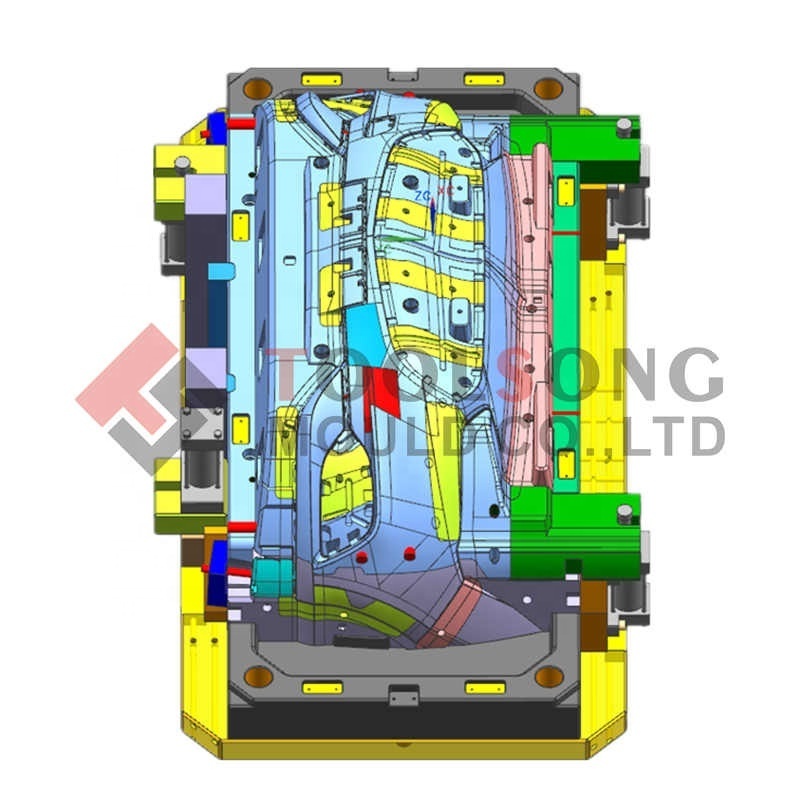

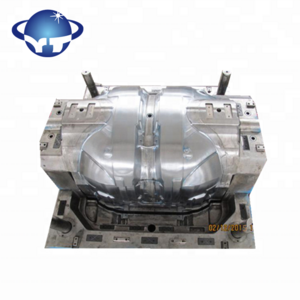

ODM Plastic Car Bumper Production Line In Taizhou

|

|

Product Material

|

PP, ABS, etc

|

|

Cavity Quantity

|

1

|

|

Core and Cavity Steel

|

718, P20, 2738, etc.

|

|

Injection System

|

YUDO/Synventive/Moldmaster hot runner, open gate

|

|

Mold Components

|

HASCO, DME, PUNCH, Misumi, etc.

|

|

Mold Life

|

300,000-500,000 shots

|

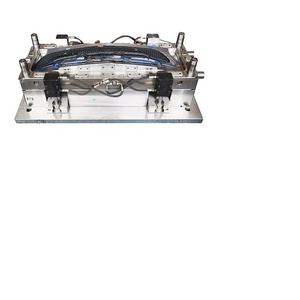

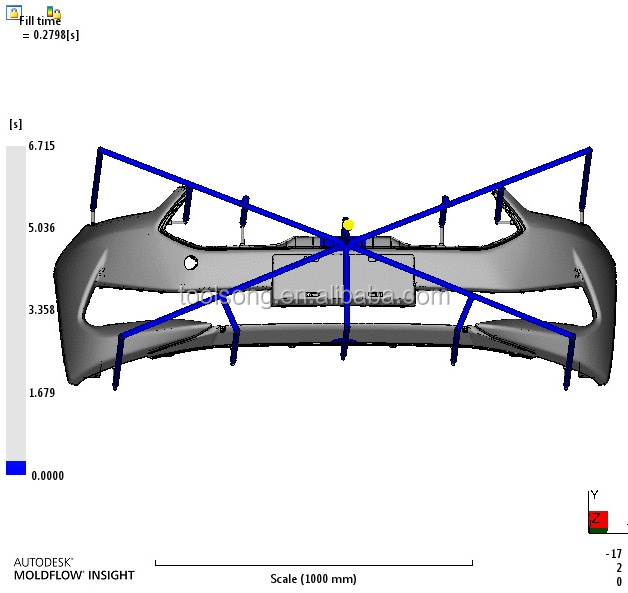

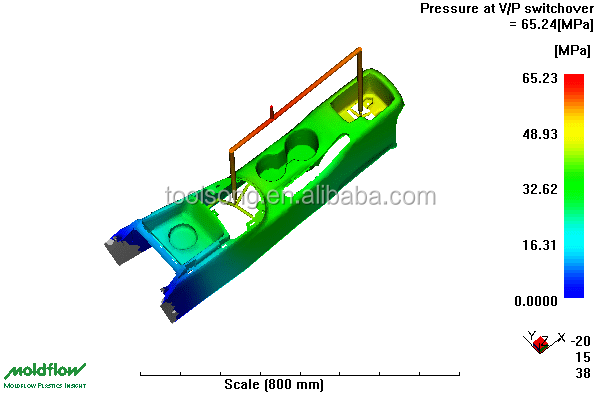

In-house Mold Flow Simulation

To Find the Best Injection Gate Before Mold Design

Part Feasibility Study, To Find Out Any Potential Risks.

Primary Tool Design, To Prepare Tool Main Steel.

F inal Tool Design For Customer's Approval Before Machining.

Mold 2D Drawings, BOM List

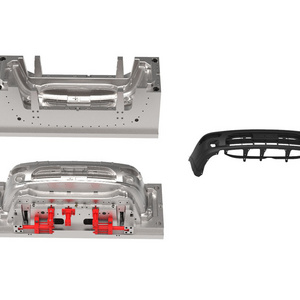

- - Project Manager Takes Full Responsibilities for Mold Quality, Cost and Delivery .

1. Project Schedule

2. Steel Certificate

3. Heat Treatment Certificate

4. Part CMM Report

5. Mold CMM Report

6. Mold Trial Report

We hav e 2 plants for manufacturing plastic toolings.

Review Meeting

Project Review before Sending Tool Design to Customer.

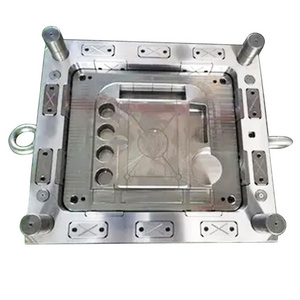

Tooling Workshop

Average Experience of Tool Makers: 16 years.

Machining Center

Equipped with 5 Axis, 3+2 Axis, CNC Milling, EDM,

Deep Hole Drilling, Die Spotting Machine, etc.Sample Room

Moulded Console, Bumper, Grille, Door Panel, Instrument Panel, Lighting, And Other Automotive Products.

5 Axis High Speed Milling

24,000 mm/min

3+2 High Speed Milling

36,000 mm/min

1) Customer shall provide tool specification as well as part picture or drawing (In STP, X-T) for quotation.

2) Toolsong will quote within 24-48 hours.

1) Quality Control in each mold manufacturing process.

2) Mold Inspection : each mold should be disassembled and inspected before shipment.

1) Tool Makers strictly follow up schedule.

2) Project Managers make preventative plan, manage and report maufacturing status.