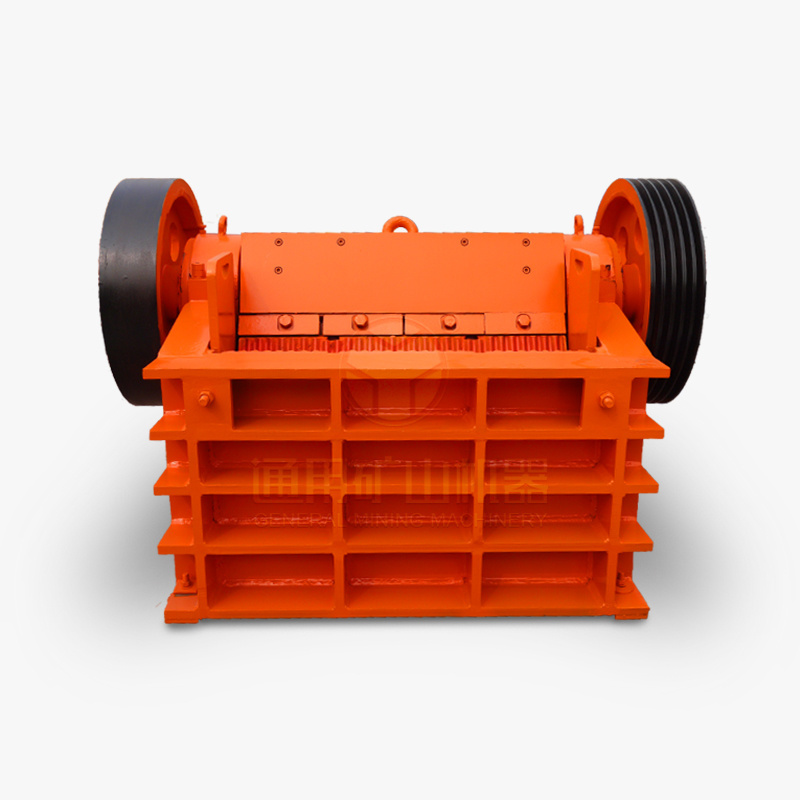

The jaw crusher is widely used in mining,metallurgical industry,building material, highway, railway, and chemical industry. Large and mediumsized jaw crusher is one of our company's leading products and it has been at the leading level in China,especially in thedesign and production of large jaw crusher.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depend on model

-

Weight:

-

15600 KG

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

Fine Stone Jaw Crusher

-

The Machines classification:

-

Building Stone Production Line

-

Function:

-

Mining Crusher Equipment

-

Usage:

-

Crushing Work

-

Applicaton:

-

Stone Process

-

Crusher type:

-

Quarry Machine Stone Crusher

-

Installation:

-

Engineer Guide

-

After sale Service:

-

Lifelong Operation Time

-

Spare parts supply:

-

Anytime

Quick Details

-

Application:

-

stone,ore,coal,sand

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TYM

-

Dimension(L*W*H):

-

Depend on model

-

Weight:

-

15600 KG

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

Fine Stone Jaw Crusher

-

The Machines classification:

-

Building Stone Production Line

-

Function:

-

Mining Crusher Equipment

-

Usage:

-

Crushing Work

-

Applicaton:

-

Stone Process

-

Crusher type:

-

Quarry Machine Stone Crusher

-

Installation:

-

Engineer Guide

-

After sale Service:

-

Lifelong Operation Time

-

Spare parts supply:

-

Anytime

Products Description

Jaw Crusher is mainly used to crush kinds of mining stones primarily, and the largest compression resistance of the material to be crushed is 320MPA.

Working principles

The pulleys are driven by motor and the movable jaw moves up and down by eccentric shaft. When the movable jaw going down, the angle between the fixed jaw and movable jaw becomes small so that the materials can be crushed; when the moving jaw rising up, the angle between the fixed jaw and moving jaw becomes large, the moving jaw leaves the fixed jaw with the function of draw bar and spring so as to discharge the crushed materials from the outlet of the crushing cavity.The jaw crusher structure is mainly composed of frame,jaw plate,toggle plate,eccentric shaft,flywheel and tension rod.The jaw plate consists of the fixed jaw and the movable jaw.

Structure of jaw crusher

Jaw crusher contains frame, eccentric shaft, big belt pulley, flywheel, side guard plate, toggle plate, back seat of toggle plate,clearance adjustable screw, reset spring, fixed jaw and movable jaw, etc. and among them the toggle plate also has insurance effect.

Features

1 Deep-cavity crushing, high efficiency and energy saving

2 High bearing capacity and stability

3 Centralized lubrication system and easy maintenance

4 Simple structure and easy maintenance

5 Multi-using of one machine, environmental friendly

2 High bearing capacity and stability

3 Centralized lubrication system and easy maintenance

4 Simple structure and easy maintenance

5 Multi-using of one machine, environmental friendly

Stone production line flow

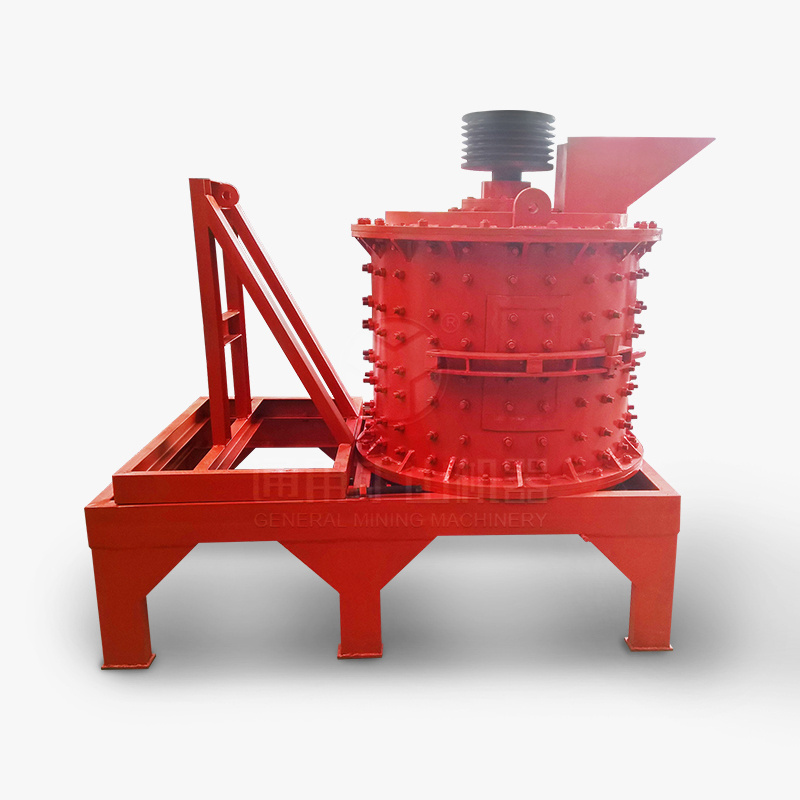

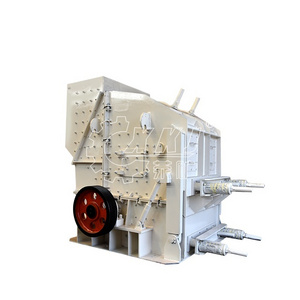

The material is first transported to the jaw crusher evenly and continuously through the vibrating feeder. After being crushed by the jaw crusher, it is conveyed to the impact crusher for secondary crushing. After the secondary crushing, the material is conveyed to the vibrating screen.During normal operation, the vibration of exciter will drive the screen mesh fixed on the screen box vibrate, and then materials will be screened. The big and small materials fall from the upper side and lower side of the screen to get them separated. (

Secondary crusher can be cone crusher, fine jaw crusher and etc,

Configure according to your requirements.

)

Technical parameters

|

Model

|

Max feeding size(mm)

|

Output adjustment range(mm)

|

Priduction capacity(t/h)

|

Power(kw)

|

Overall dimension(mm)

|

|

PE200 × 350

|

180

|

18-70

|

3-10

|

11

|

1000x 870x 990

|

|

PE250 x 400

|

200

|

20-50

|

5-20

|

15

|

1430 x 1310 x 1340

|

|

PE400 x 600

|

350

|

40-100

|

15-60

|

30-37

|

1700 x 1732 x 1653

|

|

PE500 x 750

|

425

|

50-100

|

40-110

|

45-55

|

2035 x 1921 x 2000

|

|

PE600 x 900

|

480

|

65-160

|

90-180

|

55-75

|

2290 x 2206 x 2370

|

|

PE750 x 1060

|

630

|

80-140

|

110-320

|

90-110

|

12655×2302× 3110

|

|

PE900 x 1200

|

750

|

95-165

|

220-450

|

110-132

|

3800 x 3166 x 3045

|

|

PE1200 x 1500

|

1020

|

150-300

|

400-800

|

160-220

|

16380×5310×3710

|

|

PEX150x250

|

125

|

10-40

|

1-3

|

5.5

|

896×745×935

|

|

PEX150x750

|

125

|

18-48

|

5-6

|

15

|

1200×1500×1200

|

|

PEX250x750

|

210

|

25-60

|

15-30

|

22-30

|

1667×1545×1020

|

|

PEX250x1000

|

210

|

25-60

|

15-50

|

30-37

|

1550×1964×1380

|

|

PEX250x1200

|

210

|

25-60

|

20-60

|

37-45

|

2192×1900×1950

|

|

PEX300x1300

|

250

|

20-90

|

16-105

|

55

|

2720×1950×1600

|

PE series jaw crusher!

PEX series jaw crusher!

Commonly Used Materials

Our stone jaw crusher can greatly reduce the operating costs. And it is of reliability and flexibility. Jaw crusher is widely used for crushing various materials like stone, granite, trap rock, coke, coal,manganese ore, iron ore, emery, fused aluminum, oxide,fused calcium carbide, lime stone, quartz, alloys. This series of jaw crusher makes a feature of great crushing ratio, uniform size of fineness , easy maintenance and less operating cost. And the jaw crusher is widely used in mining, metallurgical industry,building material, highway and chemical industry.

Recommend Products

Our Customers Site

Customize solutions according to customer requirements!

We are able to design and manufacture complete crusher plants with capacity from 30tph to 500tph, and to provide optimum and most economical solutions according to customers' requirements on stone specifications, output, application, etc.

This is our stone production line in Indonesia!

The customer's requirements:

raw material: marble, capacity: 400 tons/hour, finished products: 0-5mm, 5-16mm, 16-31mm.

Equipment configuration: 2xZSW490*130 vibrating feeder, 2 PE750x1060 jaw crusher, 2xPYD2200 cone crusher, 2x3YZS2460 vibrating screen, a VSI1140 sand making machine.

raw material: marble, capacity: 400 tons/hour, finished products: 0-5mm, 5-16mm, 16-31mm.

This is our stone production line in Philippine!

The customer's requirements:

raw material: limestone, capacity: 100 tons/hour, finished products: 0-5mm, 5-10mm, 10-20mm.

Equipment configuration: ZSW380x96 vibrating feeder, PE600x900 jaw crusher, PF1214 impact crusher, 3YZS1860 vibrating feeder.

raw material: limestone, capacity: 100 tons/hour, finished products: 0-5mm, 5-10mm, 10-20mm.

Equipment configuration: ZSW380x96 vibrating feeder, PE600x900 jaw crusher, PF1214 impact crusher, 3YZS1860 vibrating feeder.

This is our stone production line in Bolivian!

The customer's requirements:

Raw material: grinite, capacity: 500 tons/hour, finished products: 0-10mm, 10-20mm, 20-30mm.

Equipment configuration: ZSW6000X1300 vibrating feeder, PE1000x1200 jaw crusher, 2 sets HP500 cone crusher, 4 sets 4YZS2470 vibrating screen.

Raw material: grinite, capacity: 500 tons/hour, finished products: 0-10mm, 10-20mm, 20-30mm.

Equipment configuration: ZSW6000X1300 vibrating feeder, PE1000x1200 jaw crusher, 2 sets HP500 cone crusher, 4 sets 4YZS2470 vibrating screen.

This is our stone production line in Vietnam!

Raw material: Barite, capacity: 40 tons/hour, finished products: 0-8mm, 8-15mm, 15-25mm.

Equipment configuration: ZSW320x90 vibrating feeder, PE400x600 jaw crusher, PYB900 spring cone crusher, 3YZS1237 vibrating screen.

Equipment configuration: ZSW320x90 vibrating feeder, PE400x600 jaw crusher, PYB900 spring cone crusher, 3YZS1237 vibrating screen.

Packing & Shipping

The package of all equipment is accord with the standard protective measures.The packing is suitable for short and long distance transportation. The moisture proof, quake proof, protected against dampness, and rustproof protection measures were taken to ensure the machine shipping to customers safely. All the machine will be packaged by plastic film.

Plastic film packaging

Large items will be wrapped in plastic film, such as jaw crusher, impact crusher, cone crusher, main mill, pipe, etc.

Box wooden packing

Small parts will be packed in wooden box, such as bolts, rubber sleeves, springs, etc

Hot Searches