- Product Details

- {{item.text}}

Quick Details

-

Names:

-

Modified PP with maleic anhydride

Quick Details

-

Place of Origin:

-

Shanghai, China

-

colour:

-

natural

-

Name:

-

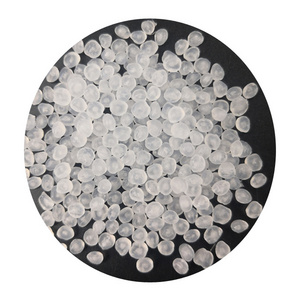

PP-g-MAH

-

Names:

-

Modified PP with maleic anhydride

1.Grafted PP of maleic anhydride&PP-g-MAH&MAH-g PP &Couping agent for PP with filler&plastic additive&PP additive.

2.SGS,RoHS.

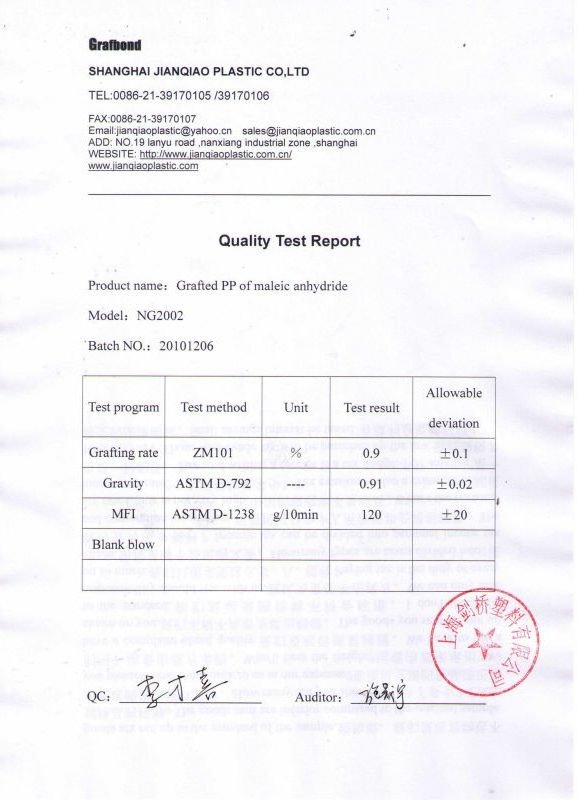

Grafted polypropylene PP-g-MAH

1. Introduction of

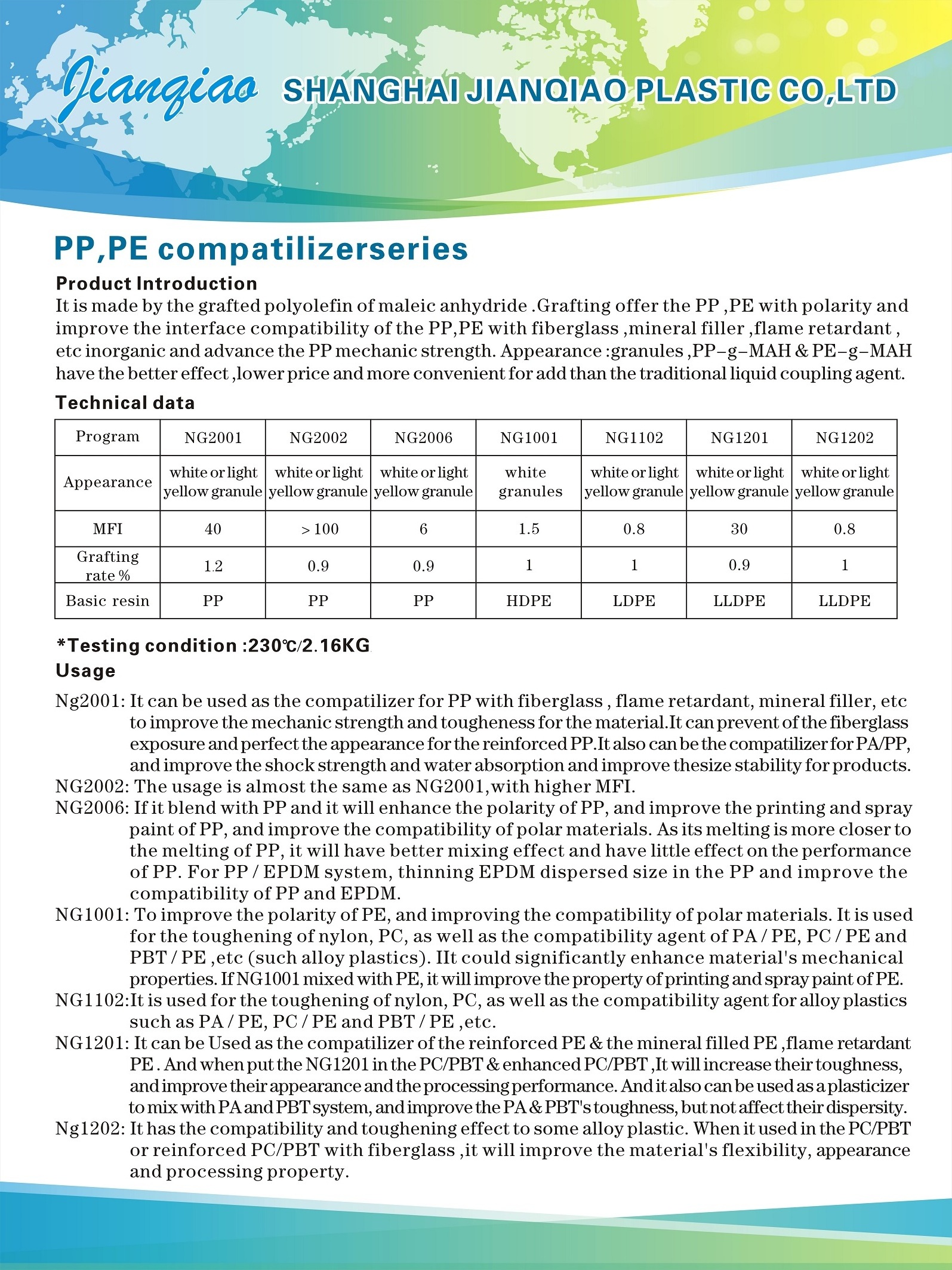

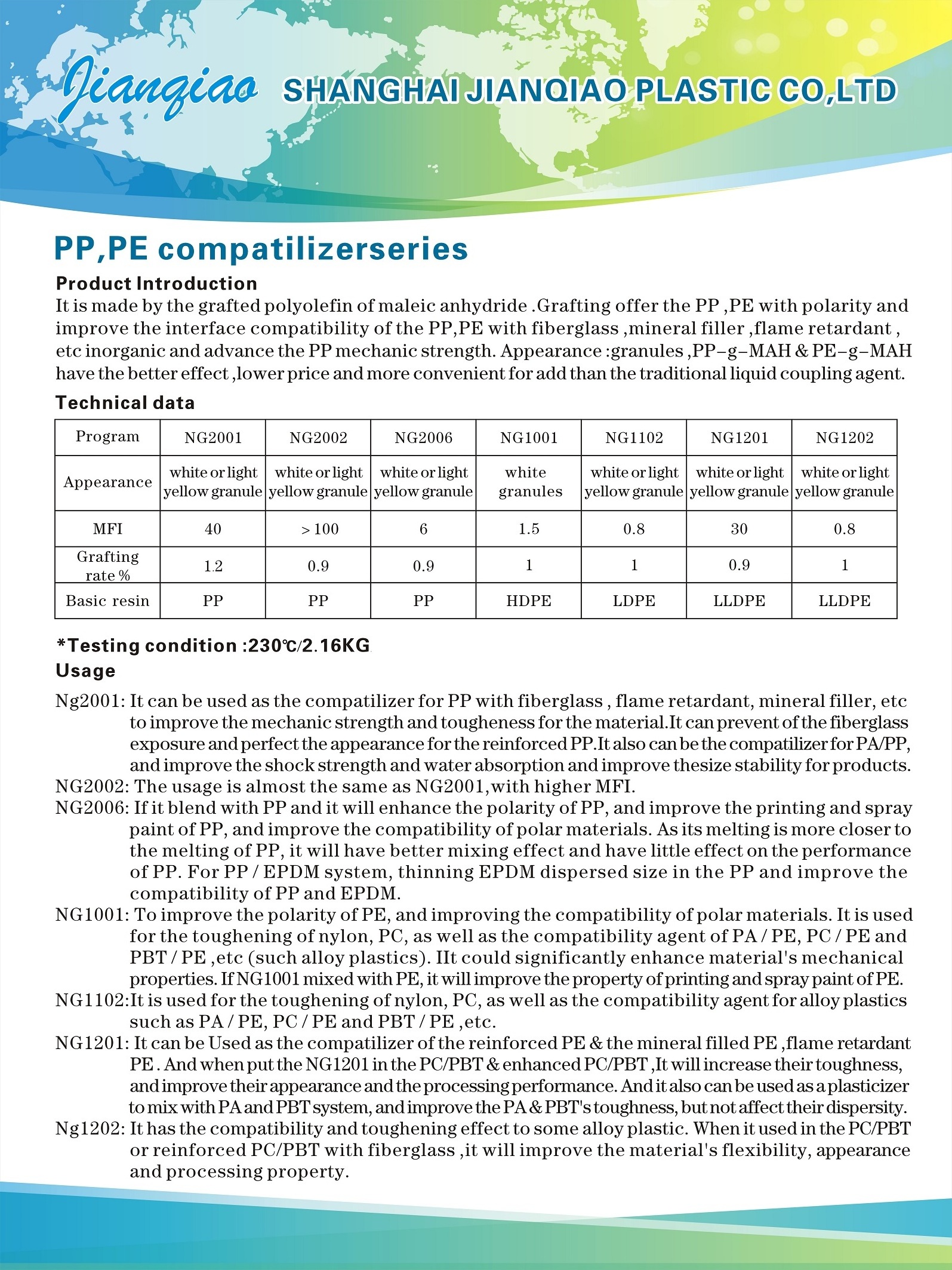

Table 1 grafted polypropylene performance

|

|

unit |

NG2001 |

NG2002 |

NG2006 |

|

Density |

g/ml |

0.90 |

0.90 |

0.90 |

|

Melt index |

g/10min |

40 |

>100 |

6.0 |

|

Base material |

|

PP |

PP |

PP |

|

Graft rate |

% |

1.0 |

1.0 |

1.0 |

2, the main purpose

NG2001: when we add some in the PP, it can improve bonding of the PP and glass fibers and inorganic fillers, such as talc .and increase the intensity of products and thermal performance. Compared with the traditional coupling, both in mechanical properties, thermal properties and the properties of hydrolysis-proof, have increased significantly, and the high molecular, it is not easy to be volatile.

NG2002: usage is the same as the above., and it has a higher melting.

NG2006:If it blend with PP and it will enhance the polarity of PP, and improve the printing and spray paint of PP, and improve the compatibility of polar materials. As its melting is more closer to the melting of PP, it will have better mixing effect and have little effect on the performance of PP. For PP / EPDM system, thinning EPDM dispersed size in the PP and improve the compatibility of PP and EPDM. Compared with NG2001, it is more suitable to the production of various alloy plastics.

3, packaging, storage and transportation

25 KGS is packed in a kraft bag. In the process of transport and storage ,Please do not to be exposed in the heavy shine and rain, In the case of wet, it can be used after the drying more than 90 for 4 hours.