- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOGDA

-

Voltage:

-

380V 50HZ 3P, Customized

-

Dimension(L*W*H):

-

18000*2500*2800MM

-

Power (kW):

-

55

-

Weight:

-

4000 KG

-

Raw material:

-

PVC, Caco3, stabilizer, etc....

-

Keywords:

-

PVC corner bead machine, pvc angel bead making

-

Main extruder:

-

SJZ55 conical twin screw extruder

-

Temperature control:

-

Omron Brand

-

Extruder main motor:

-

SIEMENS BEIDE or SIMO

-

Frequency inverter:

-

ABB brand

-

Extruder main motor power:

-

22KW

-

Machine color:

-

White and green, can be customized

-

Processing Type:

-

Exturding Machine

-

Punching method:

-

Online with cutting

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

37 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOGDA

-

Voltage:

-

380V 50HZ 3P, Customized

-

Dimension(L*W*H):

-

18000*2500*2800MM

-

Power (kW):

-

55

-

Weight:

-

4000 KG

-

Raw material:

-

PVC, Caco3, stabilizer, etc....

-

Keywords:

-

PVC corner bead machine, pvc angel bead making

-

Main extruder:

-

SJZ55 conical twin screw extruder

-

Temperature control:

-

Omron Brand

-

Extruder main motor:

-

SIEMENS BEIDE or SIMO

-

Frequency inverter:

-

ABB brand

-

Extruder main motor power:

-

22KW

-

Machine color:

-

White and green, can be customized

-

Processing Type:

-

Exturding Machine

-

Punching method:

-

Online with cutting

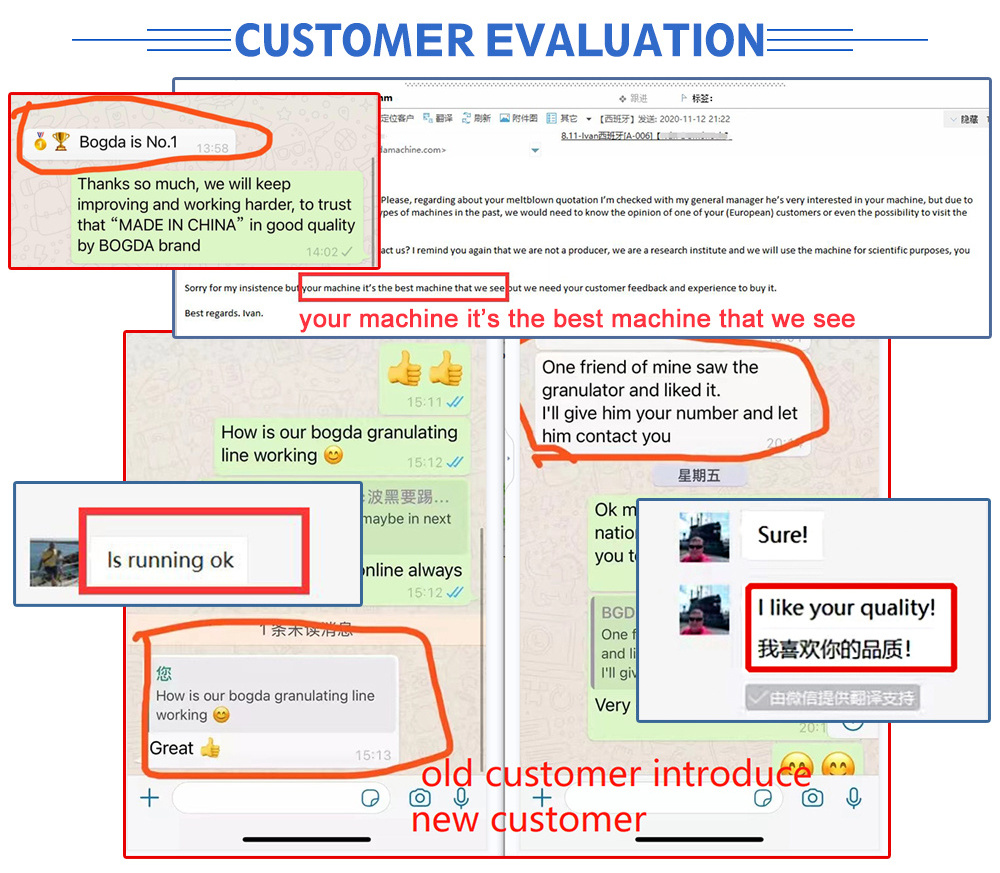

Why Choose BOGDA?

1. Bogda uses internationally renowned brand motors and appliances for customers to buy locally.

2. Bogda can do plant planning for customers and maximize benefits with minimal cost.

3. Bogda adopts special screw, long life, high plasticization.

4. Bogda machinery high degree of automation, low energy consumption, high output.

5. Bogda equipment design is reasonable, installation and disassembly is simple and convenient.

6. Once the customer has any problem in installing and operating the machinery, Bogda will arrange corresponding technicians to provide online video guidance for the customer in the shortest time or go to the customer's factory to solve the problem if the government policy allows.

2. Bogda can do plant planning for customers and maximize benefits with minimal cost.

3. Bogda adopts special screw, long life, high plasticization.

4. Bogda machinery high degree of automation, low energy consumption, high output.

5. Bogda equipment design is reasonable, installation and disassembly is simple and convenient.

6. Once the customer has any problem in installing and operating the machinery, Bogda will arrange corresponding technicians to provide online video guidance for the customer in the shortest time or go to the customer's factory to solve the problem if the government policy allows.

Product Description

B

Automatic PVC Corner Bead Fiberglass Mesh Covering Gluing Machine

PVC plastic protection corner bead include internal corner and external corner beads, which is specially design to protect the doorside strips, wall corners, window corners. During operation, it's coated with fiberglass mesh together, which can solve corner problem, like not straight, not flat, easy damaged, popular used in indoor decorations.

|

Rigid PVC Drywall Profile Angel Corner Bead Extrusion Line PVC Corner Bead Making Machine

|

|

|

||

|

NO

|

Machine Name

|

Quantity

|

||

|

1

|

Screw conveyor for extruder

|

1 SET

|

||

|

2

|

SJZ55/110 Conical twin screw extruder

|

1 SET

|

||

|

3

|

Extrusion mould

|

1 SET

|

||

|

4

|

Haul off machine

|

1 SET

|

||

|

5

|

Online punching machine with cutting

|

1 SET

|

||

|

6

|

Final stacker

|

1 SET

|

||

PVC Drywall Profile Angel Corner Bead Extrusion Line PVC Corner Bead Making Machine

1. Main extruder: SJZ55 conical twin screw extruder, can make 2 cavities, 4 cavities, 6 cavities

2. Extrusion mould, raw material we use 3Cr17

3. Haul off machine, customzied rubber block

4. Online punching and cutting in one unit

5. Final stacker

Related Machines

Packing & Delivery

FILM packaging and plywood case packaging for BOGDA Trade PET Plastic Sheet Extrusion Machine Line For Food Packaging Blister

Hot Searches