- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CHIYU

-

Voltage:

-

380

-

Dimension(L*W*H):

-

1500 3000 4500

-

Weight (KG):

-

300 kg

-

Automatic Grade:

-

Autmatic

-

Motor:

-

Siemens Beide

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

ISO9000

-

Product name:

-

Vacuum Conveyor

-

Keyword:

-

Transfer Conveyor

-

Feature:

-

High Capacity

-

Advantage:

-

Lower Cost

-

Capacity:

-

5-20t/h

Quick Details

-

Power:

-

2.2 KW

-

Warranty:

-

2 years

-

Width or Diameter:

-

30mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CHIYU

-

Voltage:

-

380

-

Dimension(L*W*H):

-

1500 3000 4500

-

Weight (KG):

-

300 kg

-

Automatic Grade:

-

Autmatic

-

Motor:

-

Siemens Beide

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

ISO9000

-

Product name:

-

Vacuum Conveyor

-

Keyword:

-

Transfer Conveyor

-

Feature:

-

High Capacity

-

Advantage:

-

Lower Cost

-

Capacity:

-

5-20t/h

Title goes here.

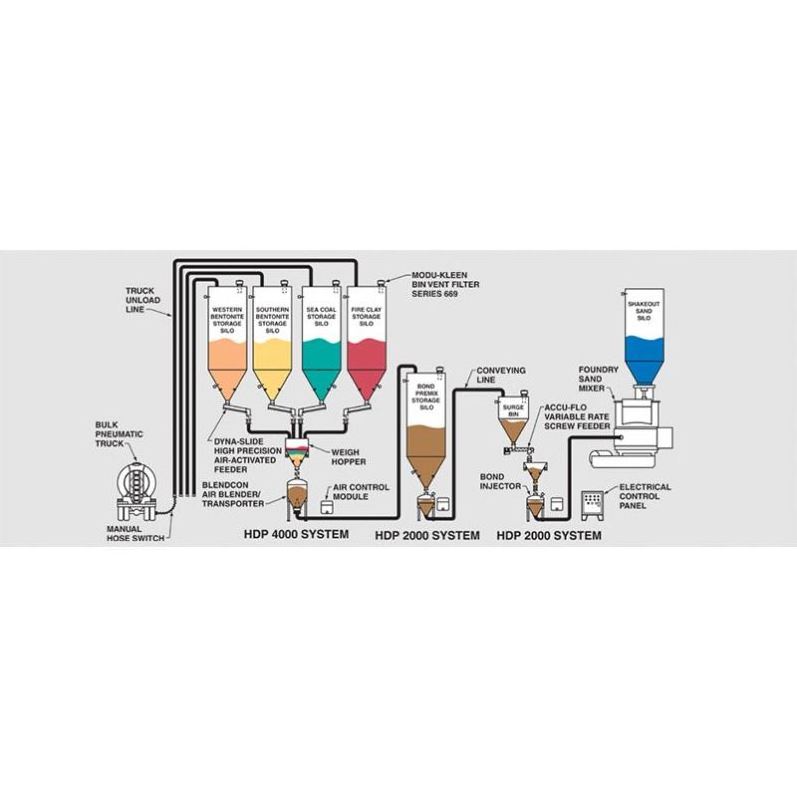

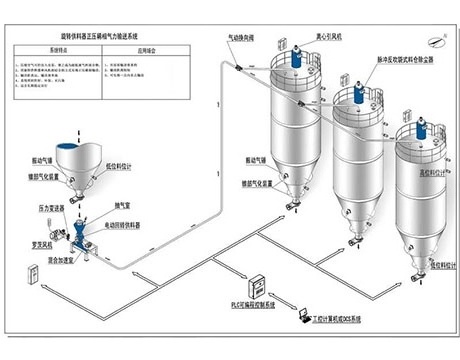

Pneumatic conveying systems

Pressure conveying systems are best employed where the product is to be conveyed from one feeding point to several delivery points

over long distances. Since the product has to be conveyed against the air pressure, locks or pressure vessels are required.

Product delivery is under atmospheric pressure and however simpler.

This pneumatic conveying system is specially designed for long distance big capacity conveying, it can convey up to 500meters in

horizontal distance, now this high efficiency conveying system has been widely used in chemical industry, plastic& rubber

industry, food industry, etc. our company has rich experience in providing system solution for powder/pellet material

conveyingmixing dosing handling, at domestic and abroad market, we have many succussful projects.

For plastic industry:

The plastic industry was one of the first industries to recognise the benefits of pneumatic handling of material and

processing,our company has designed and installed many turnkey systems for many polymar produceers and users, nowadays, this

pneumatic conveying system has been adopted and used for many window & door profile factory, PVC pipe factory, SPC/LVT/WPC

flooring factory,etc.

Our pneumatic conveying system characteristic:

* Extremely high efficiency

* Dust-free, closed system

* Hygienic and operator-friendly

* Space and height saving design

* Flexible configuration of pipes

* Reliable conveying

* Gentle and low-wear for product and plant

In principle, the conveying of bulk materials in the production process can now be automated in virtually all instances. A variety

of pneumatic conveying solutions is now available for use according to the respective bulk material, the nature of the task and

the available space.In principle, pneumatic conveying systems are differentiated in pressure and vacuum mode. A combination of

these both systems isalso possible.

Pressure conveying systems are best employed where the product is to be conveyed from one feeding point to several delivery points

over long distances. Since the product has to be conveyed against the air pressure, locks or pressure vessels are required.

Product delivery is under atmospheric pressure and however simpler.

This pneumatic conveying system is specially designed for long distance big capacity conveying, it can convey up to 500meters in

horizontal distance, now this high efficiency conveying system has been widely used in chemical industry, plastic& rubber

industry, food industry, etc. our company has rich experience in providing system solution for powder/pellet material

conveyingmixing dosing handling, at domestic and abroad market, we have many succussful projects.

For plastic industry:

The plastic industry was one of the first industries to recognise the benefits of pneumatic handling of material and

processing,our company has designed and installed many turnkey systems for many polymar produceers and users, nowadays, this

pneumatic conveying system has been adopted and used for many window & door profile factory, PVC pipe factory, SPC/LVT/WPC

flooring factory,etc.

Our pneumatic conveying system characteristic:

* Extremely high efficiency

* Dust-free, closed system

* Hygienic and operator-friendly

* Space and height saving design

* Flexible configuration of pipes

* Reliable conveying

* Gentle and low-wear for product and plant

In principle, the conveying of bulk materials in the production process can now be automated in virtually all instances. A variety

of pneumatic conveying solutions is now available for use according to the respective bulk material, the nature of the task and

the available space.In principle, pneumatic conveying systems are differentiated in pressure and vacuum mode. A combination of

these both systems isalso possible.

Hot Searches