- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZHUOZHILAN MACHINERY

-

Voltage:

-

380V

-

Weight:

-

2200 KG

-

Dimension(L*W*H):

-

2250*1250*2300mm

-

Type:

-

22 Briquette Machines

-

Production Capacity:

-

0.5-1.5T/h

-

Product name:

-

Hydraulic toner forming machine

-

Applicable raw materials:

-

Charcoal powder, coal powder, etc.

-

Raw material size:

-

less than 5mm

-

Finished shape:

-

Square, round,Round or customized according to customer needs

-

Moisture of material:

-

less than 12%

-

Power:

-

18.5-32.5KW

-

Colour:

-

According to customer's demand

-

Materials:

-

Carbon Steel

Quick Details

-

Warranty:

-

2 years

-

Core Components:

-

PLC, Bearing, Gear, Motor, Thruster, Forming cylinder, Heating coil, Reducer, Spiral blade

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

ZHUOZHILAN MACHINERY

-

Voltage:

-

380V

-

Weight:

-

2200 KG

-

Dimension(L*W*H):

-

2250*1250*2300mm

-

Type:

-

22 Briquette Machines

-

Production Capacity:

-

0.5-1.5T/h

-

Product name:

-

Hydraulic toner forming machine

-

Applicable raw materials:

-

Charcoal powder, coal powder, etc.

-

Raw material size:

-

less than 5mm

-

Finished shape:

-

Square, round,Round or customized according to customer needs

-

Moisture of material:

-

less than 12%

-

Power:

-

18.5-32.5KW

-

Colour:

-

According to customer's demand

-

Materials:

-

Carbon Steel

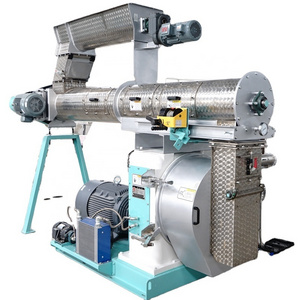

Product Description

Brief introduction:

1. It is a machine can press charcoal powder into small briquettes, round shape, cubic shape, strip shape,ringlike shape, etc, it can press with special words, company name, brand name, telephone number, etc. The mold can be customized according to the clients’ shape and size.

2. The popular shapes are round, flat, cube etc. It is mainly used to shisha charcoal.

Product Characteristics:

1)raw materials can be: charcoal powder, coal powder, sawdust, etc.

2)briquette height can be adjusted.

3)whole machine includes: main machine, PLC, hydraulic system, discharging conveyor.

4)It can customize different shapes.

5)final charcoal briquettes are usually used for shisha charcoal.

2)briquette height can be adjusted.

3)whole machine includes: main machine, PLC, hydraulic system, discharging conveyor.

4)It can customize different shapes.

5)final charcoal briquettes are usually used for shisha charcoal.

Specification

|

Model

|

CJL-22

|

CJL-36

|

|

|

Yield

|

19-36 pieces/time

8 times/mint

|

22-48pieces/time

8 times/mint

|

|

|

power

|

15+2.2+0.75kw

|

15+2.2+0.75kw

|

|

|

pressure

|

150kn

|

250kn

|

|

|

Applicable

materials

|

Charcoal power, coal powder or any powders from material.

|

|

|

|

Feeding raw materil

|

<3mm

|

<3mm

|

|

|

Diameter of briquettes

|

20*20*20mm,22*22*22mm25*25*25mm orcustomization

|

45*10*50mm, 50*15*60mm

55*15*70mm or customization

|

|

|

Oversize

|

3000*1400*2200mm

(include out conveyor)

|

3000*1500*2600mm(include out conveyor)

|

|

|

Weight

|

2000kg

|

2500kg

|

|

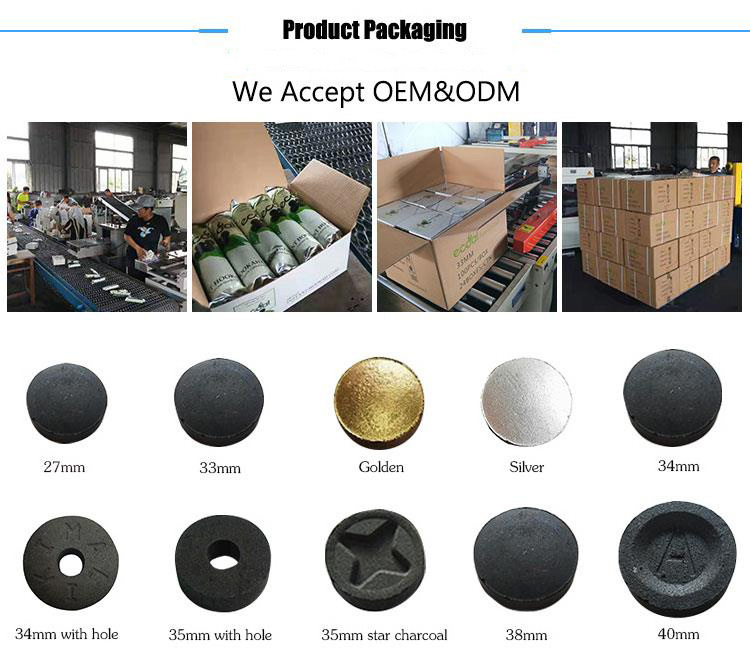

Raw Materials & Finished Products

This equipment can

produce round, square, convex-concave, rectangular and triangular shaped sheets

; various special shapes can be customized according to customer requirements, the surface of the finished product is smooth and clean, and the pressure and density of the equipment can be adjusted by itself.

Production Line

1). Make your material become charcoal by carbonizing.

2). Then crush the charcoal into powder less than 2mm.

3). Owing to charcoal powder have no stickness, so you need to add some binder into it and mix.

4). Use hookah making machine to press mixed charcoal into different shape and sizes.

5). The last but not least is drying, put final product dry by dryer, then finished.

2). Then crush the charcoal into powder less than 2mm.

3). Owing to charcoal powder have no stickness, so you need to add some binder into it and mix.

4). Use hookah making machine to press mixed charcoal into different shape and sizes.

5). The last but not least is drying, put final product dry by dryer, then finished.

Customer Photos

Packing & Delivery

Packaging

1. First of all the machine with plastic film.

2. According to the size and weight, use wooden or metal box, fixed the machine into the box. (box materials can be used as your requirements).

3. Required of the machine parts will be placed on a fixed container to avoid collision and wear or lost.

1. First of all the machine with plastic film.

2. According to the size and weight, use wooden or metal box, fixed the machine into the box. (box materials can be used as your requirements).

3. Required of the machine parts will be placed on a fixed container to avoid collision and wear or lost.

Our Service

Before service:

(1).According to our customers special requirements, provide the most suitable project design, process design and the purchaseprogram.

On sale service:

(1).Manufacturer the equipments as the contact appears at first time after receive your deposit.

(2).Inspect the machine before shipping to confirm the machine runs normally.

(3).Arrange the delivery timely.

After-sales service:

(1).We promised 24 hours on line to solve customers' concerns.

(2).We have engineer overseas available to instruct the installation and operation

(1).Manufacturer the equipments as the contact appears at first time after receive your deposit.

(2).Inspect the machine before shipping to confirm the machine runs normally.

(3).Arrange the delivery timely.

After-sales service:

(1).We promised 24 hours on line to solve customers' concerns.

(2).We have engineer overseas available to instruct the installation and operation

Hot Searches