- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

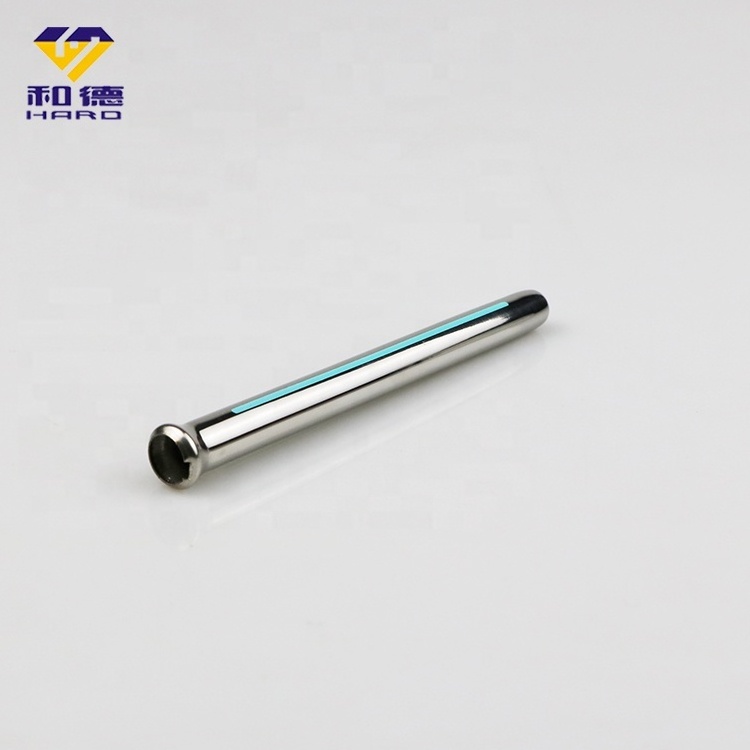

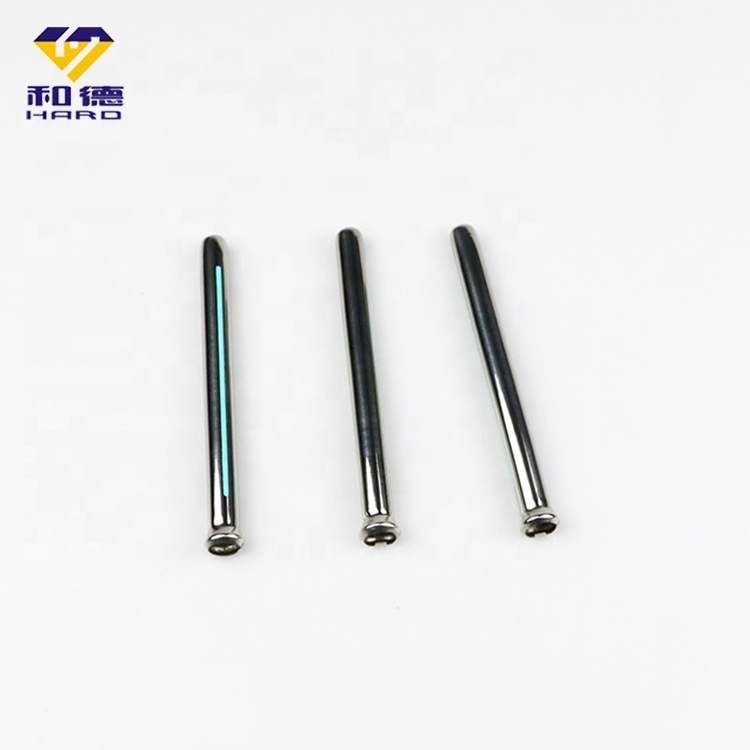

Stainless steel vibrator shell for sex toy

-

Process:

-

Stamping, Welding, etc

-

Material:

-

Stainless Steel, Aluminium, Carbon Steel, Copper, Brass, etc.

-

Drawing Format:

-

3D/CAD/DWG//STEP/PDF

-

Size:

-

Client's Drawings

-

Service:

-

Customized OEM

-

Tolerance:

-

Generally +/-0.03 mm

-

MOQ:

-

Small Orders Accepted

-

Surface Treatment:

-

Powder Coating, Anodize, Plating, Brushed, Polish, etc.

-

Certificate:

-

ISO9001:2015

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HARD

-

Model Number:

-

HDOS-34

-

Product Name:

-

Stainless steel vibrator shell for sex toy

-

Process:

-

Stamping, Welding, etc

-

Material:

-

Stainless Steel, Aluminium, Carbon Steel, Copper, Brass, etc.

-

Drawing Format:

-

3D/CAD/DWG//STEP/PDF

-

Size:

-

Client's Drawings

-

Service:

-

Customized OEM

-

Tolerance:

-

Generally +/-0.03 mm

-

MOQ:

-

Small Orders Accepted

-

Surface Treatment:

-

Powder Coating, Anodize, Plating, Brushed, Polish, etc.

-

Certificate:

-

ISO9001:2015

|

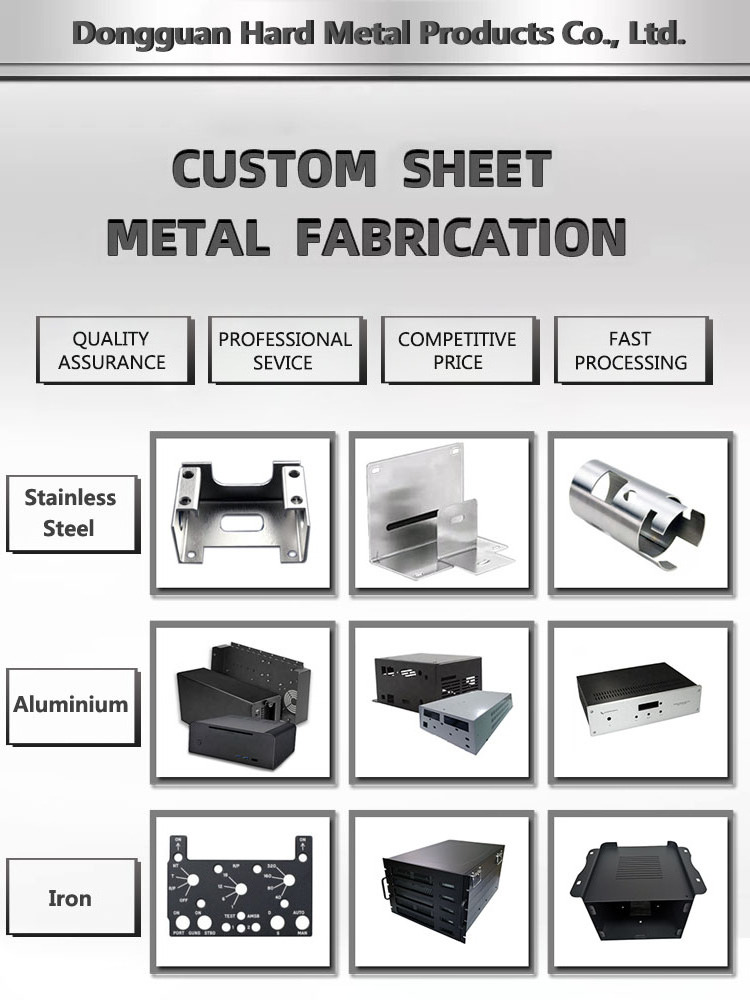

Sheet Metal Fabrication

|

|

|

||

|

Capability

|

Manufacturing based on drawing

|

|

||

|

|

OEM service

|

|

||

|

Drawing Formats

|

PDF, PRO-E, CAD, STEP, Solid Works, UG, etc.

|

|

||

|

Fabrication Process

|

Laser cutting, bending, welding, forming, stamping, deep drawing, punching, rolling, shearing, etc.

|

|

||

|

Material Used

|

Aluminum, stainless steel, iron, galvanized steel, brass, copper, cold rolled steel, hot rolled steel, etc.

|

|

||

|

Thickness(Laser Cut)

|

16 mm max carbon steel

|

|

||

|

|

8 mm max stainless steel

|

|

||

|

|

5 mm max aluminium

|

|

||

|

|

5 mm max copper & brass

|

|

||

|

Certificate

|

ISO 9001:2015

|

|

||

|

Sheet Metal Products

|

Bracket, enclosure, frame, panel, cover, etc.

|

|

||

|

Industry Focus

|

Agricultural, auto, truck, transportation

|

Military, oil field, packaging

|

||

|

|

Chemical, machine tool, medical, pharmaceutical

|

|

||

CUSTOM SERVICE

Our services include: customized finished products, various metal parts, various sheet and tube profile processing, various surface treatment, etc.

*Custom metal parts:

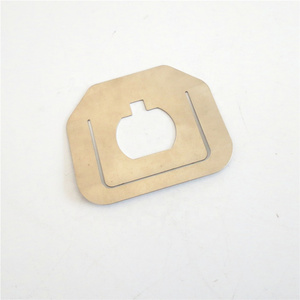

1) Custom sheet metal parts: laser cutting parts, bending parts, etc.

2) Custom stamping parts.

3) Custom deep drawing parts.

4) Custom die casting parts.

5) Custom lathe parts.

6) Custom springs...

*Material to Choose:

Stainless steel, aluminium, carbon steel, galvanized steel, cooper, brass, various alloys, etc.

*Surface Treatment:

Brushed, polish, mirror polish, anodize, zinc plated, powder coating, IP coating, spray paint, sand blasting, etc.

*Custom Logo:

Laser logo, silkscreen paint logo, etched logo, stamping logo, water transfer paint logo, etc.

Welcome to visit us for cooperation.

2) Custom stamping parts.

3) Custom deep drawing parts.

4) Custom die casting parts.

5) Custom lathe parts.

6) Custom springs...

*Material to Choose:

Stainless steel, aluminium, carbon steel, galvanized steel, cooper, brass, various alloys, etc.

*Surface Treatment:

Brushed, polish, mirror polish, anodize, zinc plated, powder coating, IP coating, spray paint, sand blasting, etc.

*Custom Logo:

Laser logo, silkscreen paint logo, etched logo, stamping logo, water transfer paint logo, etc.

Welcome to visit us for cooperation.

Why Choose Us

1.[Quality Assurance]

We attach great importance to quality. We have ISO 9001:2015 certificate for quality assurance. We always make samples to check quality before mass production; We always do final inspection before the shipment. And third-party inspection is welcome.

2.[Competitive Price]

Since we are manufacturer, we could offer factory price. It must be lower than that traders offer.

Cost savings to a certain extent.

3.[Rich Production Experience]

Our factory established in 1991.

We have more than 20-year experience in custom metal products.

4.

[Excellent Service]

From raw material to final finished goods, we could offer visualization service so that our clients could know production progress. We will keep you informed of production. And we also follow up the logistics until you receive the goods.

5.[Fast Production]

We have a complete production line that can quickly manufacture the product customized.

6.[Fast Respond]

We provide 24-hour online service, please feel free to contact us at any time.

Hot Searches