Note:The last pellet length can be adjusted.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50Hz

-

Dimension(L*W*H):

-

3100*1300*2550mm

-

Weight:

-

3450 kg

-

Warranty:

-

One Year

-

Product name:

-

poultry feed pellet mill

-

Main motor power:

-

160kw

-

Conditioner power:

-

7.5 Kw Poultry Feed

-

poultry feed pellet Yield:

-

4-18t/h livestock feed pellet mill

-

Feeder power:

-

2.2kw for feed pellet mill

-

Diameter of ring die:

-

508mm

-

Motor:

-

Siemens

-

Pellet mill bearing:

-

NSK or SKF

-

Pellet forming rate:

-

98%

-

Quality Control:

-

Using 2mm thicker steel plate than industrial standard

-

Certification:

-

CE ISO SGS

Quick Details

-

Max. Capacity:

-

15 ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Strongwin

-

Voltage:

-

380V/50Hz

-

Dimension(L*W*H):

-

3100*1300*2550mm

-

Weight:

-

3450 kg

-

Warranty:

-

One Year

-

Product name:

-

poultry feed pellet mill

-

Main motor power:

-

160kw

-

Conditioner power:

-

7.5 Kw Poultry Feed

-

poultry feed pellet Yield:

-

4-18t/h livestock feed pellet mill

-

Feeder power:

-

2.2kw for feed pellet mill

-

Diameter of ring die:

-

508mm

-

Motor:

-

Siemens

-

Pellet mill bearing:

-

NSK or SKF

-

Pellet forming rate:

-

98%

-

Quality Control:

-

Using 2mm thicker steel plate than industrial standard

-

Certification:

-

CE ISO SGS

Product Description

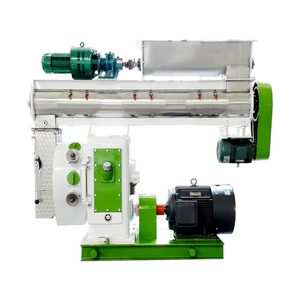

Animal Feed Pellet Machine/Poultry Feed Pellet Mill

Yield:1-15T/H

Tell us what you needs, you can get the solution that suits you.

P.S. : Price is not fixed because of exchange rate,pls contact supplier to get the newest price.

SZLH Feed Pellet Machine Stable and classical gear driving,non-slipping,can really ensure the production output. Low

noise,optimized ring die,maximum output. SZLH poultry feed pellet making machine adopt high-precision gear drive,advanced flexible

coupling,for high productive efficiency;Application: for making cattle, geese, pig, duck, chicken, sheep, rabbit, and other

animals, livestock and poultry feed.

noise,optimized ring die,maximum output. SZLH poultry feed pellet making machine adopt high-precision gear drive,advanced flexible

coupling,for high productive efficiency;Application: for making cattle, geese, pig, duck, chicken, sheep, rabbit, and other

animals, livestock and poultry feed.

|

Model

|

SZLH508 Feed Pellet Machine

|

|

Yield

|

4-18TPH

|

|

Main Motor

|

160KW

|

|

Voltage

|

3phase 380V,50Hz Can be customized)

|

|

Conditioner

|

304 stainless steel

|

|

Pellet specification

|

φ2,φ3,φ4.5,φ5,φ6,φ8,φ10mm

|

|

Diameter of ring die

|

Φ508mm

|

|

Speed of ring die(r/min)

|

287r/min

|

|

Amount of roller

|

2

|

|

Shaping rate of pellet

|

≥ 95%

|

|

Motor

|

Siemens Motor

|

|

Bearing

|

SKF Bearing

|

How to Work

It has the better raw material versatility, which can be suitable for pelletizing many kinds of raw material, such as corn, broom corn, wheat, beans, oil seed meal and other materials .

-

Scope of Application

Application: for making cattle, geese, pig, duck, chicken, sheep, rabbit, and other animals, livestock and poultry feed.

You can make 2-8 mm diameter animal feed pellets. Such as 2-4mm diameter chick feed pellets and pig feed pellets.2-5mm rabbit feed pellet, 4-8mm cattle or sheep feed pellets.

Detailed Images

Feeder

Feeder spindle, screw, sleeve, paddle are 304 stainless steel,bearing is SKF brand,longer life.

Feeding motor

Feeding motor we choose Inverter Siemens motor,the motor noise lower, the operating current is more stable Overload capacity stronger!

Conditioner motor pulley

Conditioner motor pulley using high strength cast steel black pulley, higher strength, higher precision, higher strength after heat treatment, more wear-resistant, longer service life, pulley balancing experiments run more smoothly, using a locking sleeve Installation, installation and removal convenient and time-saving, and will not cause damage to the pulley!

Conditioner

1.Conditioner spindle, paddle, bolt ,wall tube are 304 stainless steel,Motor is Siemens motor 2. Conditioner paddle stainless steel castings, bolts fixed installation, angle adjustable, but other factory is welding, the angle can not be adjusted. Conditioner can be adjusted by adjusting the paddle then adjust the material to stay time in conditioner. This is the welding pad can not do!

Pellet machine door

Pellet machine door with 304 stainless steel, other use ordinary carbon steel, pellets from the machine high temperature, moisture, ordinary carbon steel life is generally about six months, and The service life of stainless steel is long-term!

SKF Bearing

Holder, the ring die, roller high-strength alloy forged pieces, the CNC machining heat treatment, high precision, high strength and long service life!

You can switch a different mold to produce animal feed particles of different sizes,for making animal feed for poultry, chicken, pig,cattle,sheep etc.

It is the feed pellet line we built for our customers.

We can provide turnkey projects for Feed production plant. Consultation Service → Design → Civil Engineering → Manufacturing→ Installation → Training Give us an order, you can get a complete feed production factory

Related Products

Packing&Shipping

♥

Wooden or metal case according to specific size of each equipment, we twine thick plastic coating for each machine.

♥

Tight the equipment in the truck without space to ensure no rubbing during the transportation.

After Sales Service

7x24 hour Service

Strongwin Factory Can Provide Turnkey Feed Plant Project

Consultation Service → Design → Civil Engineering → Manufacturing→ Installation → Training

Customized Solutions

100% Quality Assurance

Support Oversea Installation

If you have any question, please contact us directly.

Company Introduction

Henan Strongwin Machinery Equipment Co.,Ltd is a joint-stock machinery manufacturing enterprise,integrating scientific reseach,production and making.Our company is located in the industy development Zone of Henan,China.

Our main products are feed pellet machine,feed pellet production line,fish feed extruder machine,pet food extruder machine and the production line.

Our company regards the product quality as the life of our company.All of our main machine motor is Siemens motor,the bearing is SKF bearing,the quality is very well.

Also We have passed relevant ISO,CE,SGS Certificate.Our machine are the recommended products in China machinery industry.We adopt highly materials and advanced processing technique,making the devices have long life and wearproof performance.Win a great reputation in domestic and abroad.

Corporate Culture

Strongwin Mission: Best machine for the world.

Strongwin Values: Customer first,teamwork,respect others,integrity,optimism and dedication.

Strongwin manufacturing guiding ideology: No one supervises us,but the God know everything.

Strongwin manufacturing basic principle: No labour saving though complicated processing,no material reduction though high cost.

Strongwin Manufacturing requirement: Build high-quality machinery with craftsman spirit.

Strongwin are your best consultant for feed pellet production line,if u have any demand,pls contact Strongwin people,we will give u the support on it.

FAQ

Q:i know little for feed machine and production line , what should i do ?

A:

please tell us your requirement, such as what kind of feed you want produce, the output you want per hour, how many raw materials you use and so on, we will design the flow diagram for you, and further our engineer will designer the whole feed factory for you depend on your site.

Q:our worker can not know how to operation the production line, what should i do?

A:

we has installation and after-sale service team,

our engineer can go to give customer installation guide. If customer need, our whole engineer team also go to customer's country.

Q:if the machine has a little mistake when produce and can not solve, what should i do?

A: please contact us immediately, by

email, WhatsApp,WEChat, or telphone

. Our worker will give you the solution.

Hot Searches