- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

OEM

-

Brand Name:

-

AOHOY

-

Body material:

-

SS 304 316L

-

MOQ:

-

5 Piece

-

End Connection:

-

Clamp

-

Delivery time:

-

Depending on quantity

-

Surface:

-

Mirror Polished

-

Type:

-

Safety Relief Valves

Quick Details

-

Port Size:

-

3/4"-1.5" K50.5

-

Warranty:

-

1 years

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

OEM

-

Brand Name:

-

AOHOY

-

Body material:

-

SS 304 316L

-

MOQ:

-

5 Piece

-

End Connection:

-

Clamp

-

Delivery time:

-

Depending on quantity

-

Surface:

-

Mirror Polished

-

Type:

-

Safety Relief Valves

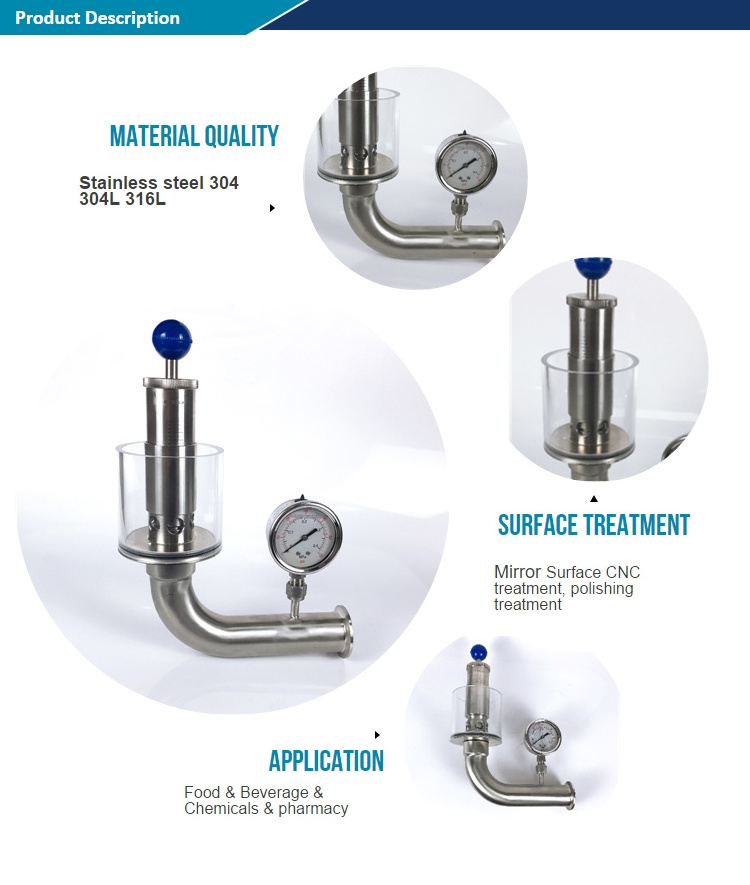

Specification

|

Pipe Size

|

3/4"-1.5"

|

|

Material

|

304/316, 1.4301/1.4404

|

|

Surface treatment

|

CNC machined Ra<0.8μm

|

|

Connection Mode

|

Clamp

|

|

Working pressure

|

0-3 bar

|

|

Working temperature

|

-10-180°C (Silicone), -10~150°C (EPDM), -40~280°C (PTFE)

|

Introducing

our new line of adjustable pressure relief valves, commonly referred to as spunding valves. These valves enable fermenters to both ferment under pressure and condition beer before transferring to a keg.

Scaled | up to 3.5 bbl

The scaled version includes an etched sleeve with a scale between 0-2 BAR, along with a pressure-calibrated spring. This version is perfect for a home or nano brewer that wants to be able to dial in pressures on the fly without having to match the release pressure using a gauge. The scaled version also features a pressure release knob to quickly and easily verify or equalize tank pressure.

Non-Scaled | up to 2 bbl

The compact non-scaled version is perfect for a homebrewer that doesn’t mind taking the extra minute or two to dial in their valve's release pressure using the gauge included with their tank

Unitank.

.

The polycarbonate cup is designed to hold sanitizer so that the tank remains 100% sanitary throughout the course of the fermentation process.

Lastly, a final note on safety, always leave the fixed-pressure PRV included with the in place, and never exceed the maximum rated working pressure of the vessel at any time during operation.

All 304 Stainless Construction

Only for use with pressure-rated Unitanks

3/4"-1.5" TC clamp interface K50.5

Removable sanitizer cup

Easy disassembly for cleaning

Real product picture

The Sspunding valve is pretty simple operation and installation. Make sure your oring and cup are fully inserted over the valve.

You will simply fill the cup half full with diluted down sanitizer similar to what you would use in a spray bottle. Twist the valve to the appropriate BAR rating ( this all depends on the processes for spunding).

If you are fermenting under pressure you would close and set after transfer a PSI or bar to your yeasts range (5 to 9 psi .3-.6 bar is common) and run this through the whole fermentation process

For safety, always leave the fixed-pressure PRV included with the vessel in place, never exceed the maximum rated working pressure of the vessel at any time during operation.

Hot Searches