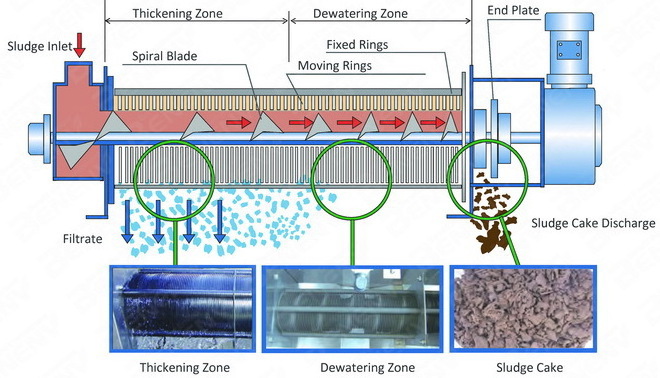

• Very low wash water usage(1/8 compared with belt press)

• Very low power consumption(1/20 compared with centrifuge)

• High cake solids

• Minimal operator requirement

• Easy to operate and maintain

• Auto start-up, run and shutdown

• Touch screen operation optional

• Sludge Flow and Cake Monitoring System

• Available with many other options like Dairy, Palm Oil, etc.