- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V / 440V / 220V / 415V

-

Dimension(L*W*H):

-

8500 * 1550 * 1600mm

-

Weight:

-

5500 kg

-

Feeding width:

-

600mm, 600 mm

-

Marketing Type:

-

New Product 2024

-

Product name:

-

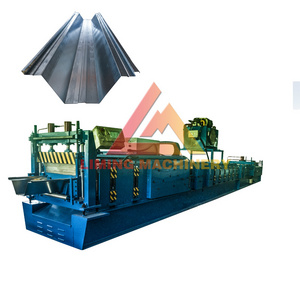

super span roll forming machine

-

Roller material:

-

45#steel Chrome Plated

-

Material:

-

Color Steel Galvanized Plate

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Application:

-

Building Construction

-

Profiles:

-

Ibr Sheets

-

Control system:

-

Taiwan Delta

-

Suitable material:

-

Color Steel Galvanised Sheet

-

Operate style:

-

Hydraulic Station

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15-20m / min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V / 440V / 220V / 415V

-

Dimension(L*W*H):

-

8500 * 1550 * 1600mm

-

Weight:

-

5500 kg

-

Feeding width:

-

600mm, 600 mm

-

Marketing Type:

-

New Product 2024

-

Product name:

-

super span roll forming machine

-

Roller material:

-

45#steel Chrome Plated

-

Material:

-

Color Steel Galvanized Plate

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Application:

-

Building Construction

-

Profiles:

-

Ibr Sheets

-

Control system:

-

Taiwan Delta

-

Suitable material:

-

Color Steel Galvanised Sheet

-

Operate style:

-

Hydraulic Station

Product Description

maquina formadora de k span big span roll forming machine super span roll forming machine

Specification:

|

Product name

|

maquina formadora de k span big span roll forming machine super span roll forming machine

|

|

|

|

|||

|

Mainframe

|

450mm,45# steel

|

|

|

|

|||

|

Middle plate

|

50mm,or according to machine demands,45# steel

|

|

|

|

|||

|

wheel

|

45# steel,surface heat treatment chfrome plating,hardness HRC 58-60

|

|

|

|

|||

|

Shaft diameter

|

100mm(depends on different design)

|

|

|

|

|||

|

Shaft material

|

Solid shaft,high quality 45# forged steel,with anti-return pad)

|

|

|

|

|||

|

Chain

|

1 inch

|

|

|

|

|||

|

Voltage

|

380V/220V/50HZ/3phase

|

|

|

|

|||

|

Model

|

different for you to choose(Our engineer and designer team service for you!! )free!!!

|

|

|

|

|||

|

Main motor power

|

5.5KW*2

|

|

|

|

|||

|

Hydraulic motor

|

5.5KW

|

|

|

|

|||

|

Hydraulic pump station

|

Gear pump

|

|

|

|

|||

|

Reducer

|

8# Gear Reducer

|

|

|

|

|||

|

Base material

|

Hot dipped galvanized steel

|

|

|

|

|||

|

Hydraulic pressure

|

10-12MPa according to the oil pump and pump motor

|

|

|

|

|||

|

Thickness

|

0.3mm-2.5mm

|

|

|

|

|||

|

Cutting method

|

Hydraulic guide column cutting

|

|

|

|

|||

|

PLC Display languages

|

Chinese,English,(Spanish or Russian)

|

|

|

|

|||

|

Color

|

All colors(standard international color)or customers samples’ color

|

|

|

|

|||

|

Length tolerance

|

±2mm

|

|

|

|

|||

|

Cutting tolerance

|

±1mm

|

|

|

|

|||

profile:

Machine Parts Detail

Name:Manual decoiler

①

Capacity:5T

② Coil diameter:450-550mm

③ Coil outer diameter:1220mm

④ Coil width:1220mm(as customers' request)

② Coil diameter:450-550mm

③ Coil outer diameter:1220mm

④ Coil width:1220mm(as customers' request)

Name:Feeding table

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat,

parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

Remarks:Pre-hand cutting is manual

parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

Remarks:Pre-hand cutting is manual

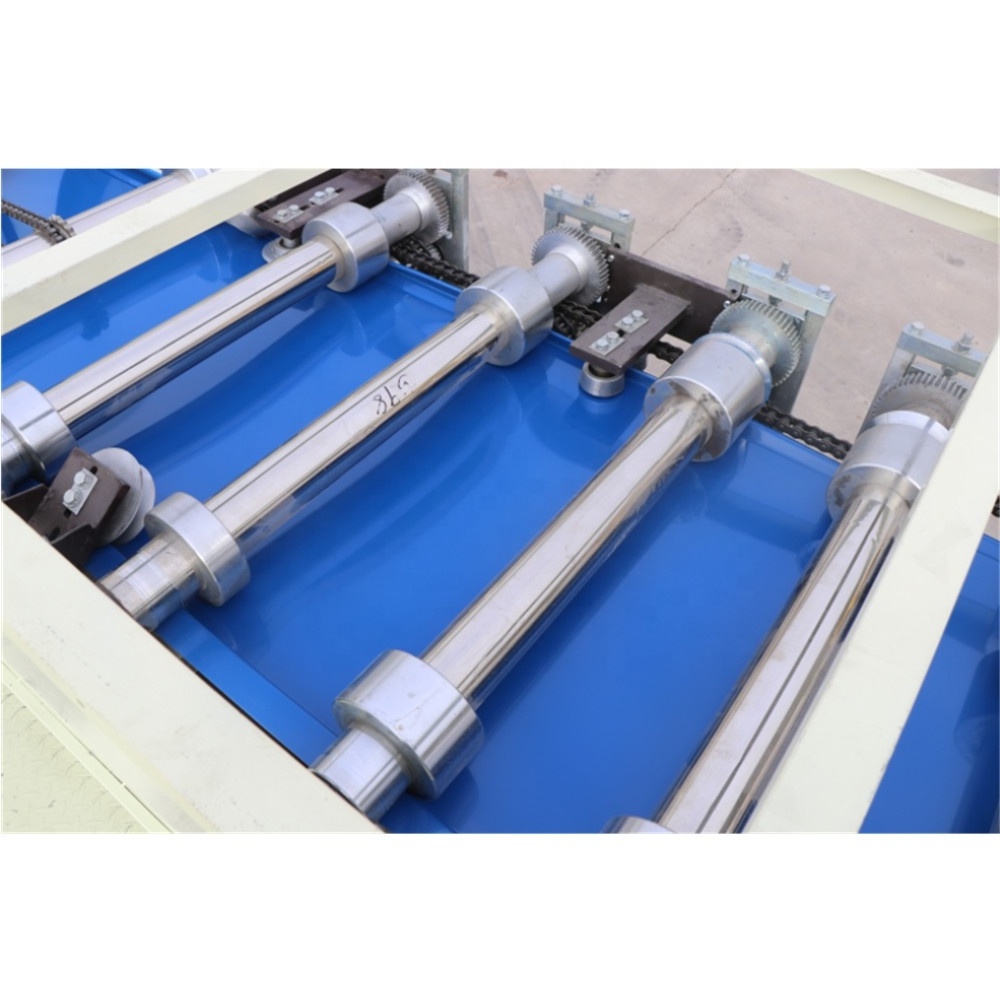

Name: Main rollers

our machine:

High grade No.45 forged steel, with digital-controlled procession, Plated with 5 um chrome coated.

other company 's machine: normal No. 20 steel with Simple polished and have no coating Influence of the machine Roller will have longer use life and ensure the products have same size, no nick on the surface.

other company 's machine: normal No. 20 steel with Simple polished and have no coating Influence of the machine Roller will have longer use life and ensure the products have same size, no nick on the surface.

①

Frame:350H steel,with 20mm middle plate support

②

Roller stations:18 stations(depend on the profile drawing)

③

Roller materila:45# steel with quenched treatment and hard chroming

④

Shaft diameter:70mm,solid

⑤

Shaft material:45# steel with tempering treatment

⑥

Motor power:5.5 kw

⑦

Speed:12-15M/min

⑧

Transmission:By chain

⑨

Voltage:220V,60HZ,3P

Name:Computer Control Cabinet

①

Control system:PLC

②

PLC brand:Delta from Taiwan

③ Frequency converter brand:Delta from Taiwan

④ Encoder:Omron

⑤ Function:Automatic control the length and quantity

③ Frequency converter brand:Delta from Taiwan

④ Encoder:Omron

⑤ Function:Automatic control the length and quantity

Name: Motor driver

①

Main motor size :5.5kw

② Brand: The famous brand from Jermany or according to customer's need

③ Solenoid valve: 2 groups

④ Hydraulic oil: 46#hydraulic oilColor:Blue (or as customer's request)

⑤ Working pressure: 12-16Mpa adjustable

② Brand: The famous brand from Jermany or according to customer's need

③ Solenoid valve: 2 groups

④ Hydraulic oil: 46#hydraulic oilColor:Blue (or as customer's request)

⑤ Working pressure: 12-16Mpa adjustable

Name :Hydraulic station power

Hydraulic pump station provide cutting power

①

Hydraulic station power: 4Kw

②

Brand:Lichao, Shanghai

③

Motor with pump capacity of tank: 45L

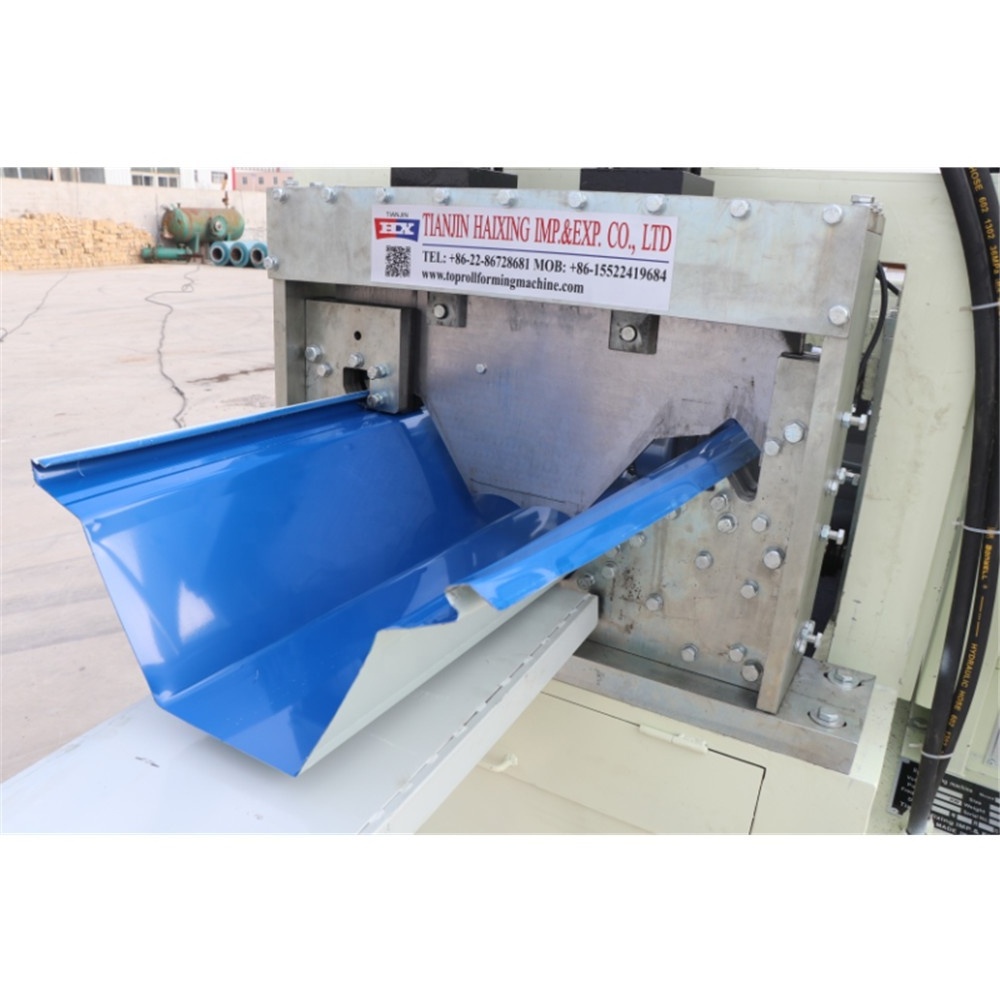

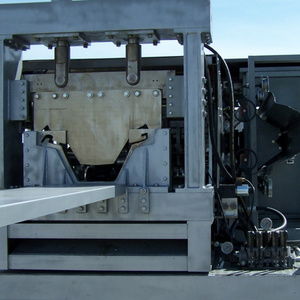

Name: Cutting head

The hydraulic system will be installed on the main roll forming machine. The important is that we install the cooling system on hydraulic oil pump, then it can support the long time working in a high temperature.

Then it can improve the working ability.

①

Work type: Hydraulic

②

Driving method: By Cylinder

③

Motor power: 5.5 kw

④

Cutter material : GB-Cr12

⑤

Cutting length tolerance: ±0.5 mm/3m

Name: Received goods table

It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products.

Application

More Styles

Hot Searches