- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

20-25 bags/min

-

Weight (KG):

-

1200

-

Voltage:

-

380V/220V/50/60Hz

-

Place of Origin:

-

China

-

Product name:

-

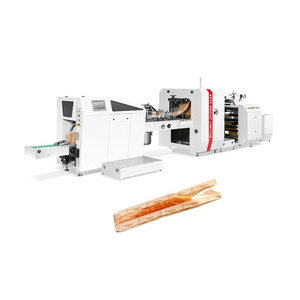

Fully Automatic Coffee Paper Bag Packaging Machine

-

Bag type:

-

Paper bag

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Function:

-

FILLING, Sealing

-

Packaging Type:

-

Bags, Pouch

-

Packaging Material:

-

Paper

-

Production Capacity:

-

20-25 bags/min

-

Weight (KG):

-

1200

-

Voltage:

-

380V/220V/50/60Hz

-

Place of Origin:

-

China

-

Product name:

-

Fully Automatic Coffee Paper Bag Packaging Machine

-

Bag type:

-

Paper bag

-

Marketing Type:

-

Hot Product 2019

|

Model

|

Bag size

|

Metering range(g)

|

Packaging speed

bags/min |

Applicable type of bag

|

|

ZD8P-2000

|

W:80-110mm L:250-350mm

|

1000-2000

|

20-25

|

Paper bag

|

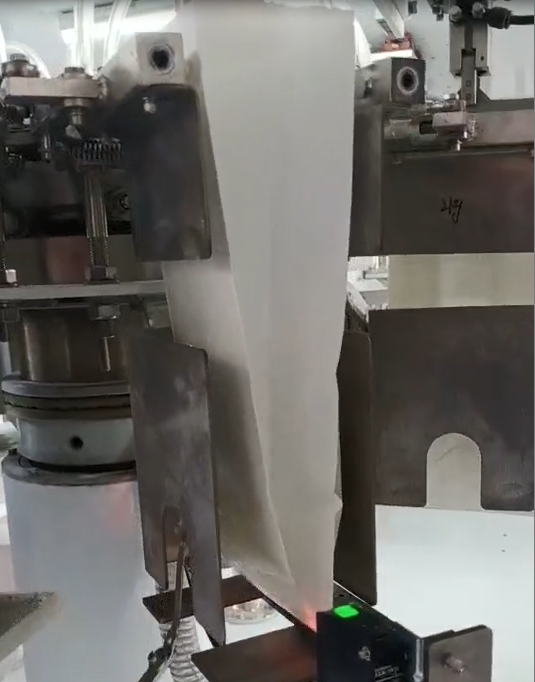

Fully Automatic Coffee Paper Bag Packaging Machine

:

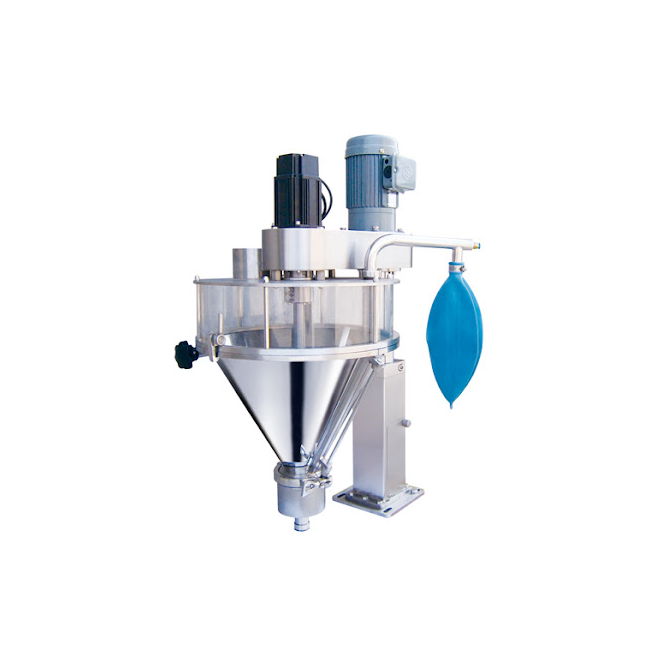

This unit is developed for quantitative packaging of tiny granular and powdery material with paper bags, and can independently complete the works of filling, sealing, metering, bar code recognition, printing, labeling, code printing, code spray coating, code stacking, etc. It is composed of quantitative filling machine, 8-station rotary packaging machine, linear conveying and stacking machine and heat shrink packaging machine through combination. It adopts advanced horizontal bag feeding mode, the bag magazine can store more packaging bags; bag suction and feeding are stable and reliable with high bag feeding efficiency and low loss of packaging material; the pattern of the packaging bag is complete and beautiful and the seal quality is good, thus improving the grade of the product.

1. Easy to operate, adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system, the man-machine interface is friendly.

2. Automatic checking function: no pouch or pouch open error, no fill, no seal.

3. Safety device: machine stop at abnormal air pressure, heater disconnection alarm.

4. The machine is easy to clean, easy maintenance.

5. The part where touch to the material is made of stainless steel.

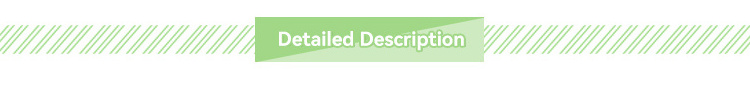

This machine can be equipped with screw auger filler mechanism. This equipment is specialized in powder ,such as milk power, grape sugar, washing powder, chemistry condiment, refined sugar,fertilizer, etc.

Q1: Are you a factory or a trading company?

A1:We are the factory with manufacturing and self-supporting import and export rights for more than 25 years.

Q2: How to choose suitable packaging machine?

A2:Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q3: How about the payment way?

A3:Payment can be T/T, L/C etc. we can provide FOB, CNF, CIF term by sea.

Q4: How to ensure the quality of the machine?

A4:We usually delivery the machine after successful inspection in our factory. We have our own quality control department,before the delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q5: How to install the equipment?

A5:We will provide manuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.

Hot Searches

![[JT-HY330] Machine for Making Kraft Paper Bag / Paper Bags Production Machine / Craft Paper Bag Making Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/22c65a5d5893304db66b95efbe1aaf82.jpg!/rotate/180/sq/300)