- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/3phase/50hz

-

Dimension(L*W*H):

-

1200*685*1190mm

-

Weight:

-

305 KG

-

Power:

-

7500

-

Working Temperature Range:

-

7 to 50 ℃

Quick Details

-

Condition:

-

New

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SHINI

-

Voltage:

-

380v/3phase/50hz

-

Dimension(L*W*H):

-

1200*685*1190mm

-

Weight:

-

305 KG

-

Power:

-

7500

-

Working Temperature Range:

-

7 to 50 ℃

Shini Industry air cooling chiller

Contactor : Kevinzhou

Whatsapp&Wechat :+86 18067841986

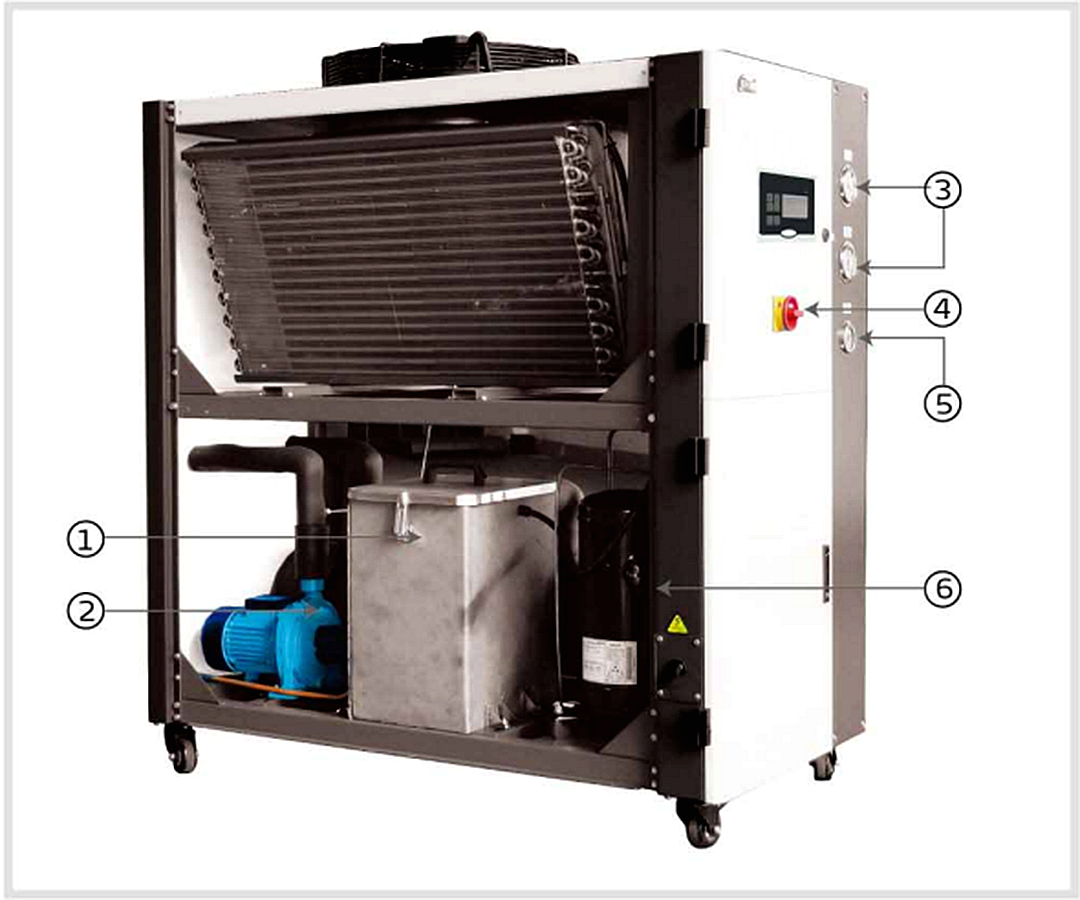

Production Description

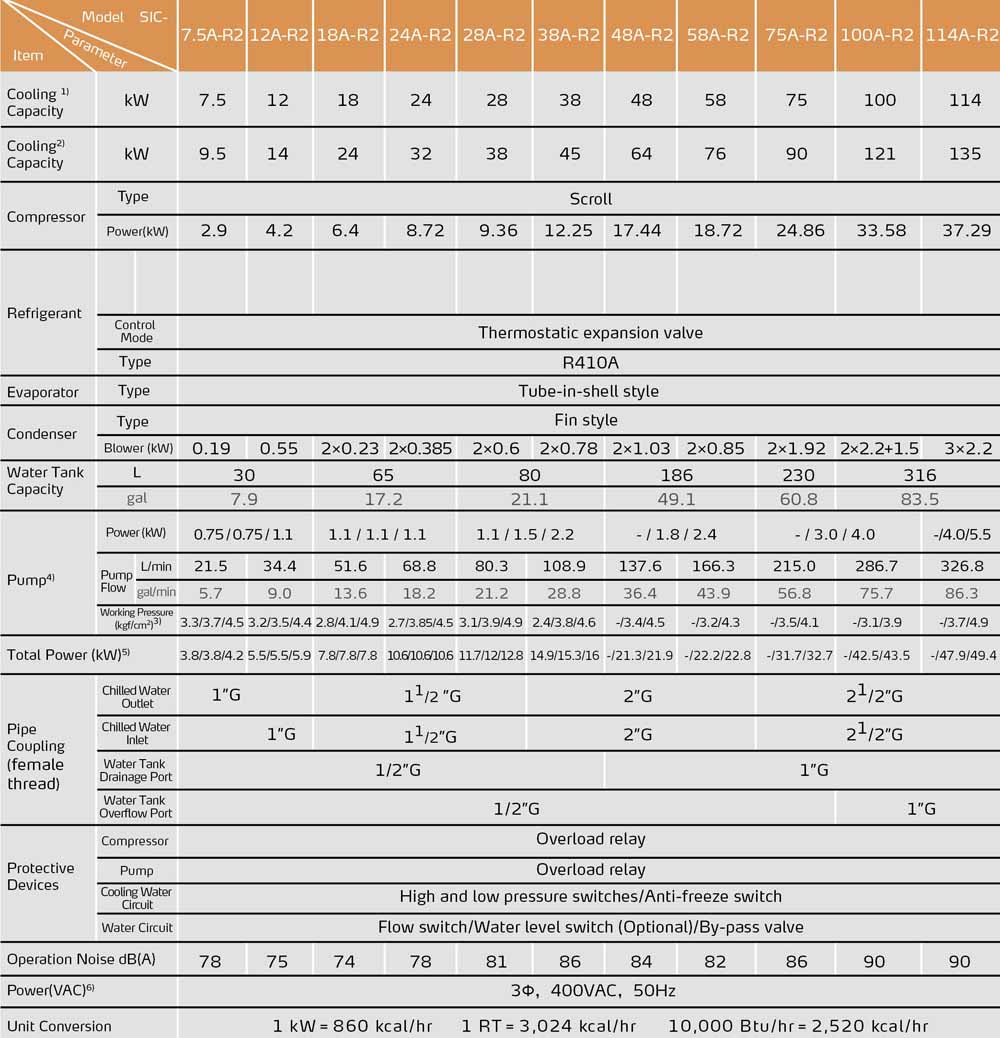

SIC-A-R2 water chiller comprises of two series; water-cooled and air-cooled, both adopt single vapor compression circuit and equipped with compressor overload protection, pump overload protection, anti-phase and open phase alarm, anti-freeze protection, pressure controller which all ensure a stable and long-service-life performance. This cooler series can cool quickly and stably to meet the customer requirements. It works based on the principle of heat and cold exchange. It is indispensable equipment in modern industry.

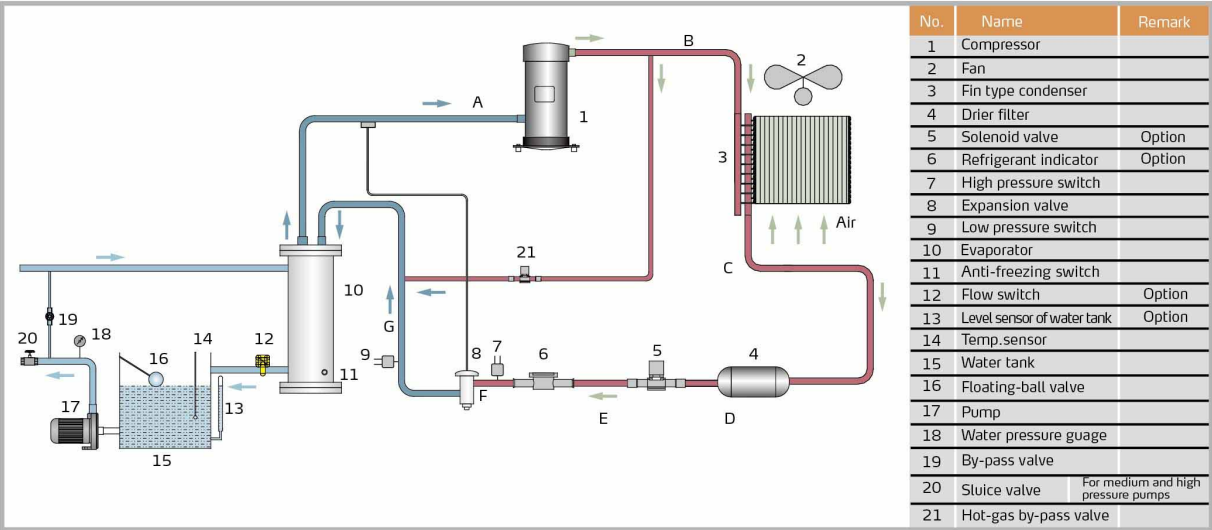

Working Principle

When SIC-A-R2 air-cooled water chiller starting-up, compressor starts working. Refrigerant is compressed into high temperature high pressure gas in the process form B to C, and then be cooled when passing through condenser and changed into liquid. Heat is taken away by the cooling air. In the process from C to D to E and F, liquid refrigerant is dried and filtered by the drier filter. After that, it passes through solenoid valve, level sensor and then reaches the expansion valve. In the process from F to G, the high pressure liquid refrigerant is throttled and depressurized by heat expansion valve and temperature goes down. In the process from G to A, chilled water absorbs the heat of process water in evaporator and returns back to the compressor. This heat exchange process repeats until process water is cooled down to requirement temperature.

Hot-air bypass function: the compressor continues working when the process water is cooled down to required temperature, then the hot-air bypass valve opens as the temperature drops to its set value. A part of the refrigerant from compressor passes through by-pass valve and then reaches evaporator, balancing out part of the machine refrigerating capacity and then goes back to compressor without passing through condenser. With the help of hot-air bypass valve, system can stay in balanced condition and meanwhile can keep control accuracy within ±1℃

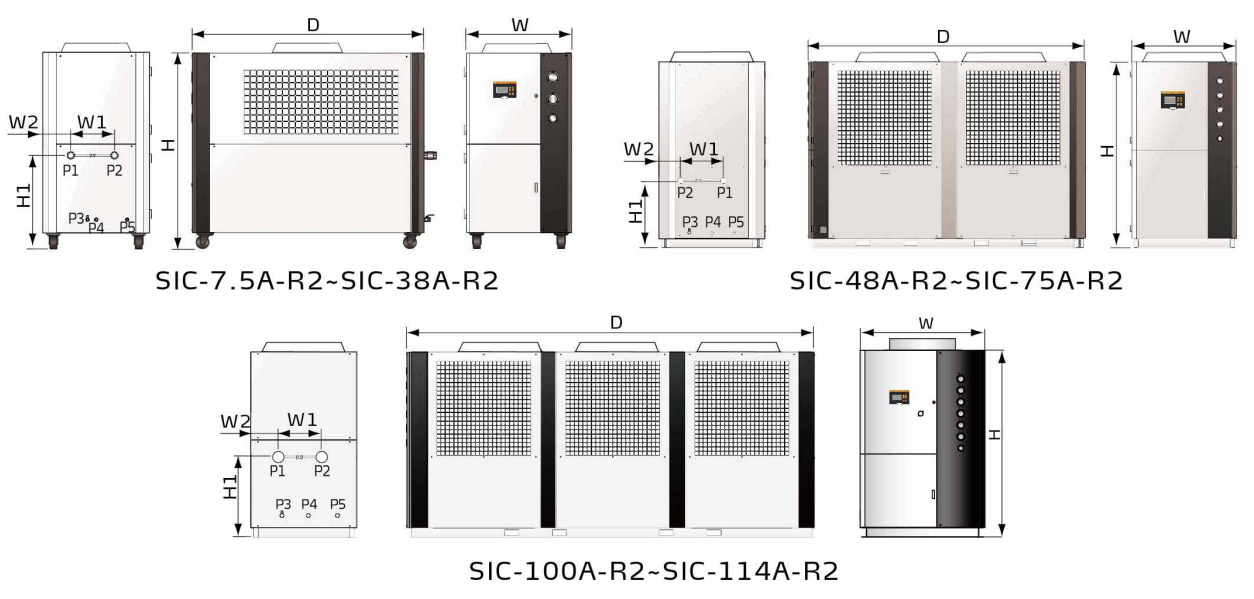

Size Information

|

Model

|

H

(mm)

|

H1

(mm)

|

W

(mm)

|

W1

(mm)

|

W2

(mm)

|

D

(mm)

|

|

SIC-7.5A-R2

|

1200

|

625

|

685

|

277

|

200

|

1190

|

|

SIC-12A-R2

|

1490

|

640

|

735

|

360

|

174

|

1320

|

|

SIC-18A-R2

|

1430

|

640

|

735

|

300

|

204

|

1610

|

|

SIC-24A-R2

|

1440

|

640

|

735

|

300

|

204

|

1610

|

|

SIC-28A-R2

|

1560

|

726

|

905

|

390

|

223

|

1782

|

|

SIC-38A-R2

|

1560

|

726

|

905

|

390

|

223

|

1782

|

|

SIC-48A-R2

|

1942

|

755

|

1208

|

400

|

257

|

2922

|

|

SIC-58A-R2

|

1942

|

755

|

1208

|

400

|

257

|

2922

|

|

SIC-75A-R2

|

1942

|

755

|

1208

|

418

|

257

|

2922

|

|

SIC-100A-R2

|

1942

|

641

|

1300

|

800

|

243

|

3475

|

|

SIC-114A-R2

|

1942

|

641

|

1300

|

900

|

255

|

3475

|

|

Model

|

P1

Chilled Water

Inlet (inch)

|

P2

Chilled Water Outlet (inch)

|

P3

Water Tank Outfall (inch)

|

P4

Water Tank Overfall (inch)

|

P5

Water Tank Refill Port (inch)

|

Weight

(kg)

|

|

SIC-7.5A-R2

|

1

|

1

|

1/2

|

1/2

|

1/2

|

305

|

|

SIC-12A-R2

|

1

|

1

|

1/2

|

1/2

|

1/2

|

315

|

|

SIC-18A-R2

|

11/2

|

11/2

|

1/2

|

1/2

|

1/2

|

400

|

|

SIC-24A-R2

|

11/2

|

11/2

|

1/2

|

1/2

|

1/2

|

420

|

|

SIC-28A-R2

|

11/2

|

11/2

|

1/2

|

1/2

|

1/2

|

530

|

|

SIC-38A-R2

|

2

|

2

|

1/2

|

1/2

|

1/2

|

540

|

|

SIC-48A-R2

|

2

|

2

|

1

|

1/2

|

1/2

|

775

|

|

SIC-58A-R2

|

2

|

2

|

1

|

1/2

|

1/2

|

800

|

|

SIC-75A-R2

|

21/2

|

21/2

|

1

|

1/2

|

1/2

|

840

|

|

SIC-100A-R2

|

21/2

|

21/2

|

1

|

1

|

1

|

1400

|

|

SIC-114A-R2

|

21/2

|

21/2

|

1

|

1

|

1

|

1600

|

After Sales Service

User-oriented: on customer service, Shini adopt considerable and flexible ways to meet all kinds of requirements.

Humanization: on product design, Shini adheres to user-friendly principle; by improving new technologies to realize design

humanization to the maximum.

One-stop: on business cooperation, Shini provides one-stop experience, and creates trustful and friendly long-term cooperation.

Company Introduction

In 1969, Shini Electrical Work Shop was established in Taipei by I-Fun Wu, who is the founder of Shini Group. Its major products include band heater, pipe heater, motor service and design plus assembly for control box. In 1975, Shin I Electrical Work Shop began to produce SHD hopper dryer and entered into the line of plastic auxiliary machinery industry. In 1978, Shin I Electrical Work Shop was renamed as “Shini Electric Heaters Co., Ltd”. Since then, Shini was officially established.

Along with the development of enterprise, Shini keeps expanding its scale. Besides Taiwan factory, Shini also has manufacturing facility respectively in Dongguan, Ningbo, Pinghu, India, and Chongqing, a technical & logistics center in USA, a branch office in German. What’s more, it setup a Corporate Technology Center, CTC is responsible for the research and development, application, global marketing and technical support for all series of Shini products. Thus, it realizes industrial distribution of “one technologies center, six manufacturing bases”.

With eight series of plastics auxiliary equipment and complete system solution, we can offer customers “one-stop shopping”experience.

In 2013, Shini accomplished rebranding and transformed to international brand for giving off more dazzling light. We develop our distinct and remarkable enterprise culture as we grow to enhance collective strength and build an outstanding internal image. we are going to follow the pace of the times, to actively take social responsibility and to make our own contribution to the development.

FAQ

Q: How many Shini manufacturing base is in the Shini Group.

A: Six manufacturing base, Shini Taipei, Shini Dongguan, Shini Ningbo, Shini Pinghu, Shini Chongqing, and Shini India. We have approximately 1,800 employees globally.

Q: How many years has the company been established?

A: The company was established in 1969.

Q: What is your standard delivery time?

A: For standard units with 230V/50Hz/1Phase or 400V/50Hz/3Phase, it's about 15~30 working days. Other voltages may take up to 30~45 working days. For customize unit may take up to 40~50 working days.