- Product Details

- {{item.text}}

Quick Details

-

Material:

-

SMC/FRP/GRP, SMC

-

Weight:

-

Based on tank size

-

Size:

-

0.5-5000m3

-

Power:

-

0

-

Weight (KG):

-

25 kg

-

Color:

-

White

-

Plate size:

-

0.5m*0.5m,1m*0.5m,1m*1m

-

Dimensions:

-

1CBM-500CBM

-

Technique:

-

Sheet molding compound

-

Application:

-

drinking water storage

-

Accessories:

-

Hot Galvanizing, SS304

-

Bottom Case:

-

U-Steel

-

Panel Thickness:

-

6mm to 24mm

Quick Details

-

Core Components:

-

Water Tank

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Long Zhuo

-

Material:

-

SMC/FRP/GRP, SMC

-

Weight:

-

Based on tank size

-

Size:

-

0.5-5000m3

-

Power:

-

0

-

Weight (KG):

-

25 kg

-

Color:

-

White

-

Plate size:

-

0.5m*0.5m,1m*0.5m,1m*1m

-

Dimensions:

-

1CBM-500CBM

-

Technique:

-

Sheet molding compound

-

Application:

-

drinking water storage

-

Accessories:

-

Hot Galvanizing, SS304

-

Bottom Case:

-

U-Steel

-

Panel Thickness:

-

6mm to 24mm

Rectangular Water Tank/ Flexible Square Water Tank/ SMC Panel Type Sectional Water Tank

The SMC water tanks are widely used in mining,enterprises, residential, hotels, restaurants and other buildings as drinking water, the water treatment, fire water and other water storage facilities.

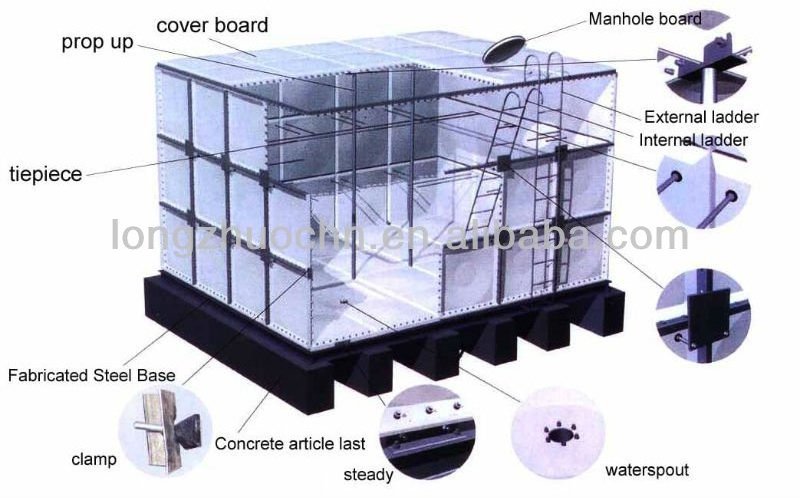

The SMC Combined Water Tank Structure:

The SMC combined water tank consists the SMC plate, sealing materials, structural article and the pipe system. The general water tank is standard design, the special water tank need to the special design. The overall strength is high, No leakage, no deformation, convenient to maintenance and repair.

1). Potable Water Storage (drinking water)

2). Rainwater Harvesting & Storage

3). Emergency Water Storage

4). Pump Chambers

5). Effluent/Acid and alkali solution treatment & Storage

6). Hospital,buildings,building site, school and other place

P.S. Besides above common fields, there're also some other special applications.

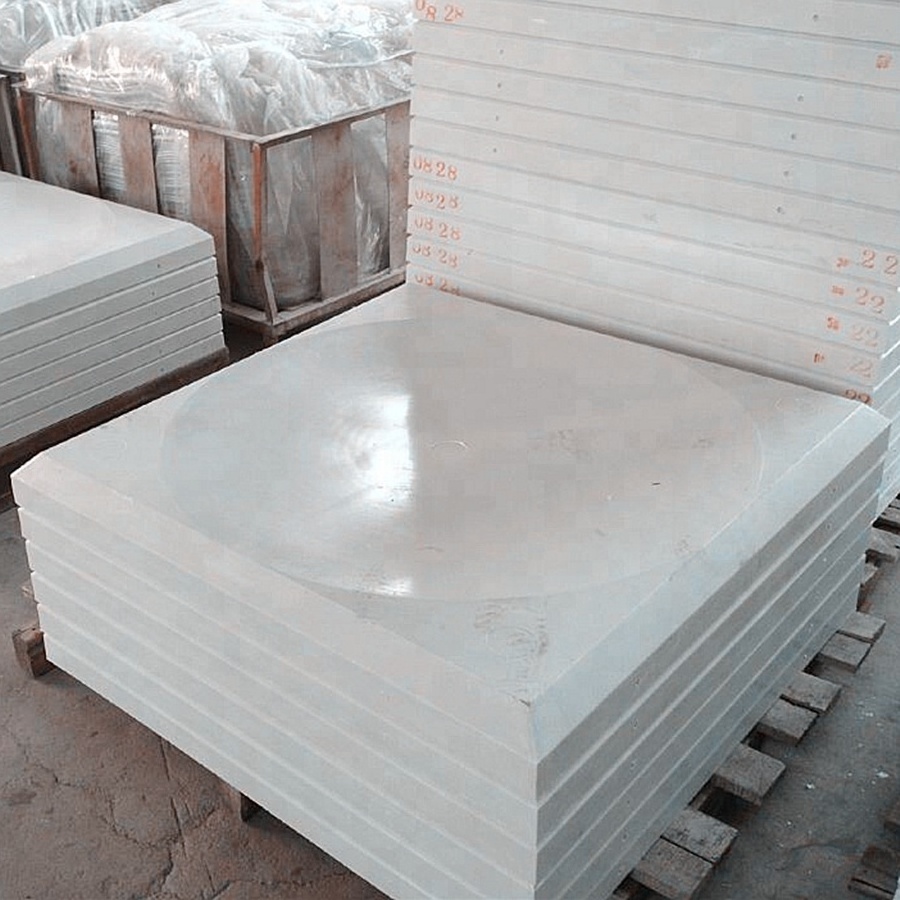

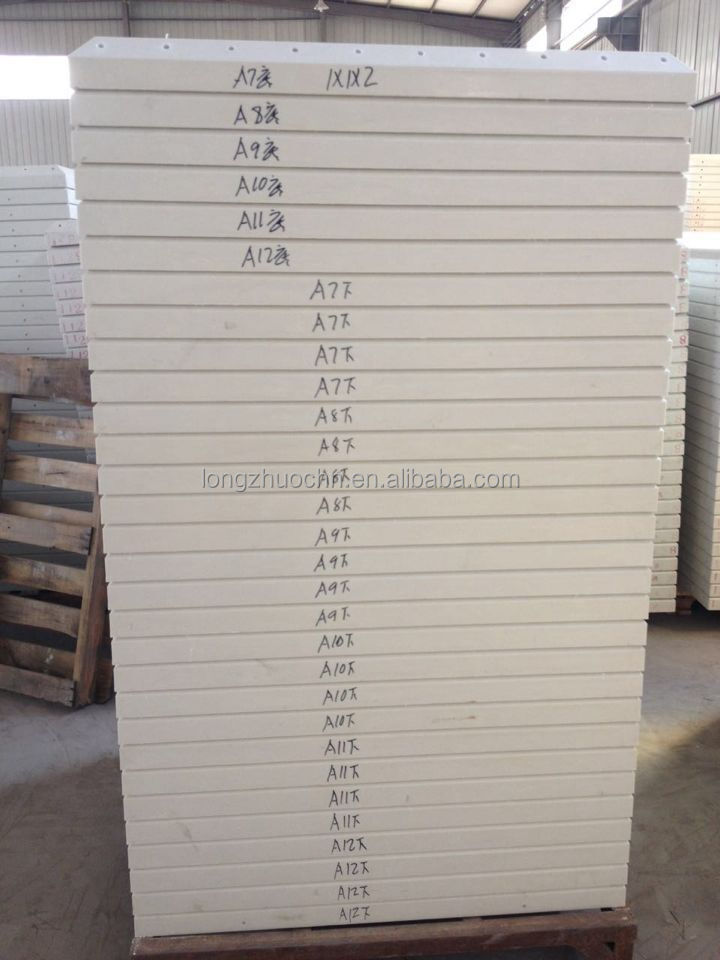

The SMC Water Tank Plate:

The panel thickness of each part in water tank is differet along with

different

tank's height:

|

Tank Height |

Thickness of each panel |

|||||

|

bottom panel |

1st layer side panel |

2nd layer side panel |

3rd layer side panel |

4th layer side panel |

cover panel |

|

|

1m |

10mm |

10mm |

/ |

/ |

/ |

5mm |

|

2m |

12mm |

12mm |

10mm |

/ |

/ |

5mm |

|

3m |

16mm |

16mm |

12mm |

10mm |

/ |

10mm |

|

4m |

18mm |

18mm |

16mm |

12mm |

10mm |

10mm |

P.S. Above thickness just for reference, actual thickness will be changed according to tank capacity,

SMC plate:

Accessories and specifications

1

. Support for Panels:

The panels shall be supported externally or internally by an adequate support system. External Reinforcement - Hot Dipped Galvanized Steel

Internal Reinforcement - Hot Dipped Galvanized or Stainless Steel 304 rod support and tie-rod

2. Sealing Materials: Non toxic Rubber foam to be used for all jointing, it is especially developed with long experience and technology on SMC products. It maintains soft itself and adhesives even at low temperatures

3. Bolts, nuts and washers for the assembly of panels: Exposed externally are hot dipped galvanized steel and in contact with water internally are hot dipped galvanized steel or stainless steel 304

4. Flange: the flanges for inlet, outlet, drainage, overflow are hot dipped galvanized steel or stainless steel 304

5. Ladders: SMC sectional tank of 1.5m depth or more shall be provided with internal ladder made up of materials same with the supports. The external ladders shall be galvanized mild steel or equivalent

6. Drainage: The dome shaped bottom panel with a concave drain panel facilitates complete and fast drainage. The concave drain panel has been designed to ensure the periodic cleaning and inspection of tank

7. Overflow Screens: it can be supplied with a screen overflow having a micro mesh filter

8. Man-hole opening & Inspection Hatches: the size can be customized; normally it is supplied with a standard size of: 600 x 600mm. the opening can be designs of bolt, seal-tight locking arrangement

9. ABS roof vent with PE insect screen

10. Float level indicator, optional SS304 for internal and external support structure are available on request

SMC Combined Water Tank Installation:

Step 1. Install steel footings on leveled concrete foundations.

Step 2. Align GRP panels to be pre-assembled.

Step 3. Place rubber sealant from ready-to-use roll between panels.

Step 4. Connect panels with bolts and nuts.

Step 5. Position bottom panel sections, and finish up base of tank.

Step 6. Position three sides of the tank.

Step 7. Position and fix roof panels and if required, roof support pipes and plates.

Step 8. Install reinforcement if required.

Step 9. Close up the tank with the fourth side.

Step 10. Finish the internal or external reinforcement.

Step 11. Fill and test.

Packing:

Contact Infor mation:

If you have any questions,please contact with us freely. Welcome your inquiry and calling.