- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7500*1700*1600Mm

-

Weight:

-

4.5T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Raw material:

-

PPGL/PPGL/GI/GL and so on

-

Roller material:

-

45#steel, surface hard chromium plating

-

Suitable to process:

-

Color Steel Ansd Foam

-

Cutting blade material:

-

Cr 12 Steel

-

Thickness:

-

0.3--0.8mm

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Roll Station:

-

15 Stands(based on machine profile type)

-

Certification:

-

CE/ISO9001

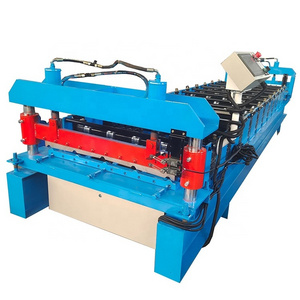

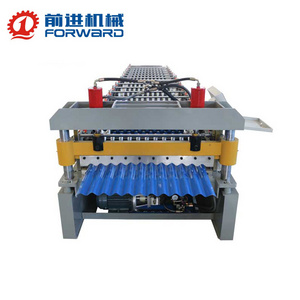

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

8-12m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7500*1700*1600Mm

-

Weight:

-

4.5T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Raw material:

-

PPGL/PPGL/GI/GL and so on

-

Roller material:

-

45#steel, surface hard chromium plating

-

Suitable to process:

-

Color Steel Ansd Foam

-

Cutting blade material:

-

Cr 12 Steel

-

Thickness:

-

0.3--0.8mm

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Roll Station:

-

15 Stands(based on machine profile type)

-

Certification:

-

CE/ISO9001

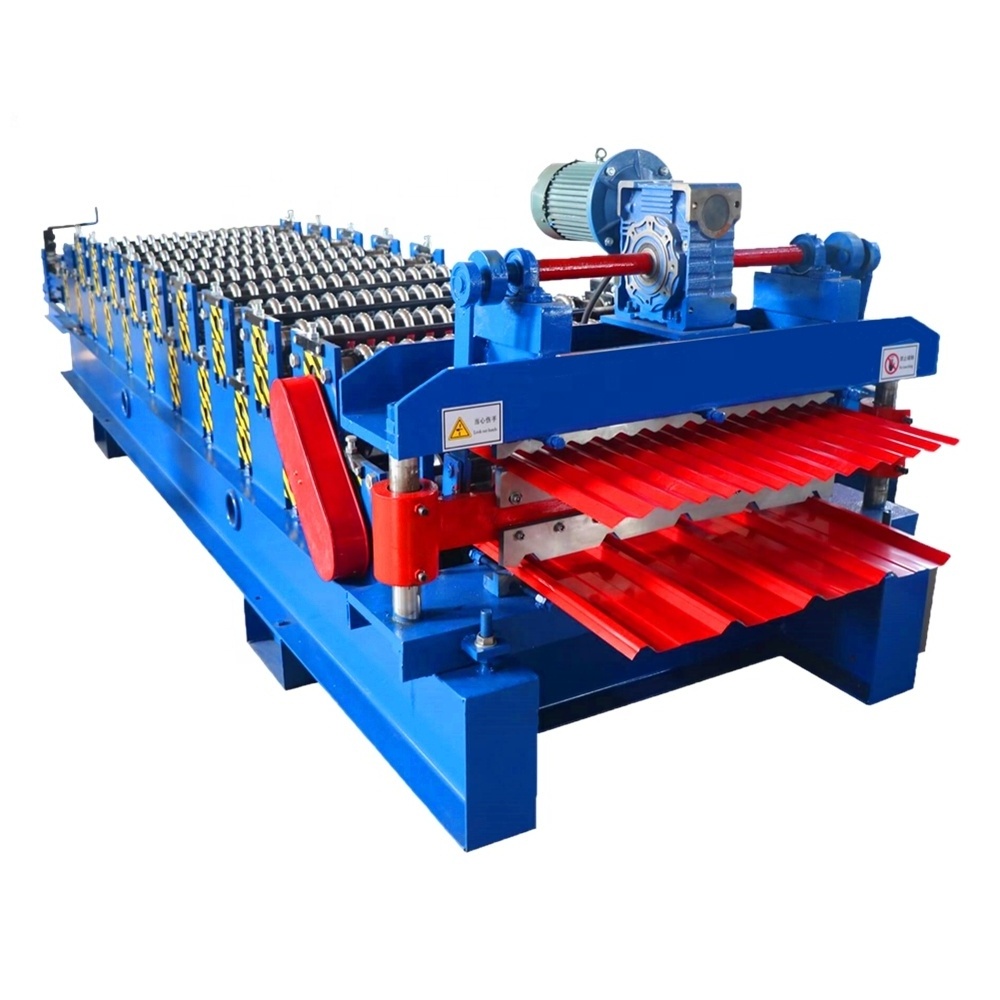

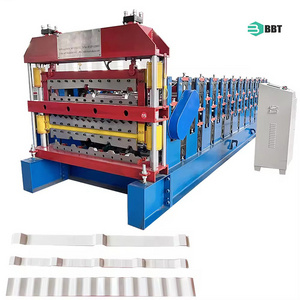

Corrugated galvanized metal roofing sheet cold roll forming machine prices main parameters

A.General details

| Suitable Material | HRB60 or equivalent(PPGI/PPGL/GI/GL) |

| Materials thickness | 0.3mm-0.8mm |

| Dimension | About 7.2*1.3*1.1m(L*W*H) , as per the drawing |

|

Length of the Sheet |

can set the length according to your infact need. It is controlled by PLC which can ensure the accuracy of ±1mm. |

| Cutting |

Automatically stop and cutting when it comes to the set length. |

B.Components Details

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 350# steel. More stable and no shaking. |

| Middle Plate |

20mm. We use thicker plates to ensure stability of our products. |

| Forming Steps | 11-20 steps, according to the drawing. |

| Shaft Material |

Φ70 mm, high grade 45# steel. Treating process: tempering- finish turning, high rigidity, hard to deform. |

|

Cutting Blade Material |

Cr12, hardness HRC60-62. Treating process: heat treatment- plane abrasion- wire electrode cutting. |

C.Electric Components

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 7 inch touch screen, easy to operate.Brand Delta or based on your need |

| PLC |

Delta Brand (Or Panasonic /Siemens ) Well-adapted to various conditions, such as moisture, electromagnetic disturbance. |

| Frequency Converter |

Sanjing ; It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

|

Length Measurement Device |

Omron, made in Japan. It features with high accuracy and stability. |

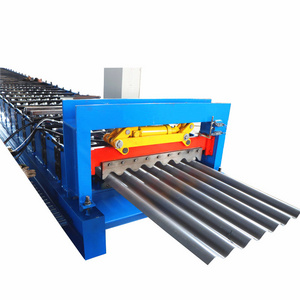

(1). Working Flow of corrugated iron sheet roofing tile making roll forming machine

Decoiling the sheet-Sheet guiding-Roll forming-Measure length-Cutting the panel-Panels to the supporter

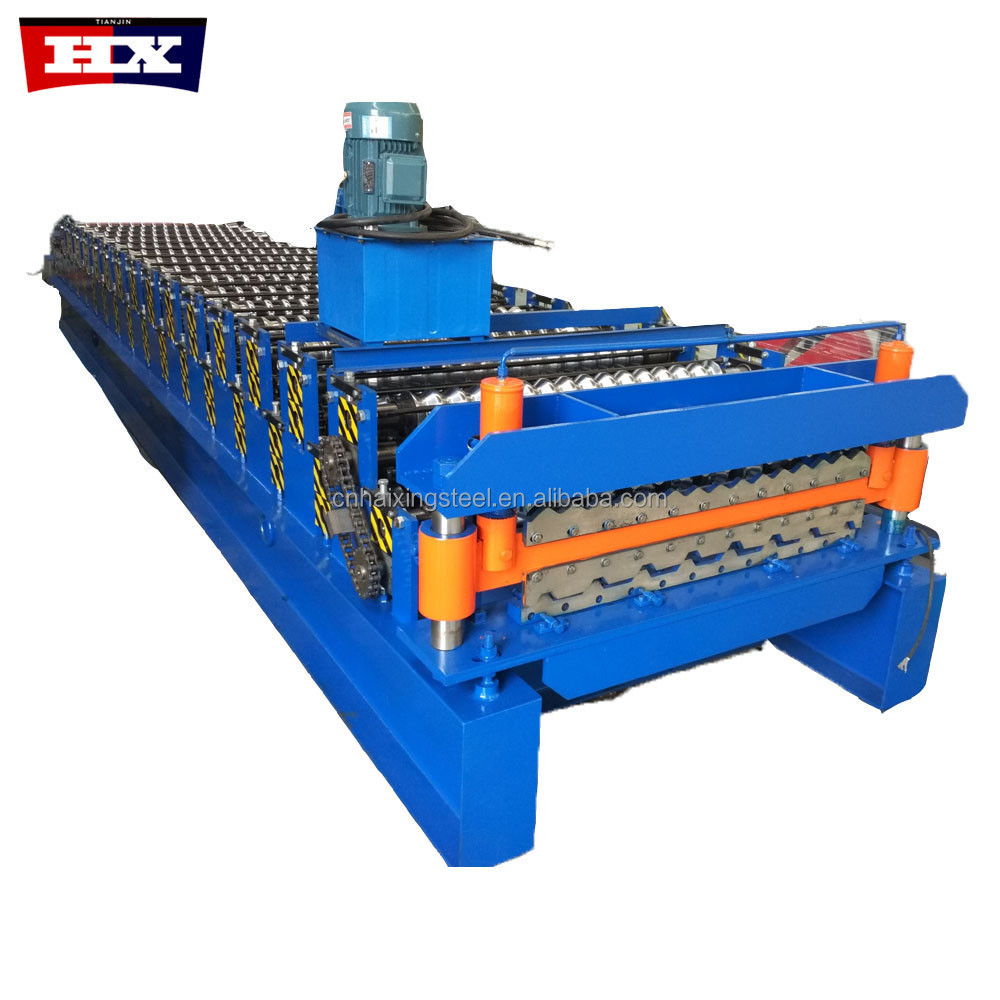

(2). More pictures of corrugated iron sheet roofing tile making roll forming machine

Uncoiler:

Usage:It is used to support the steel coil and uncoil it in a turnable way.

Passive uncoil pulled by roll forming system

Loading capacity:5T Uncoiling width:1250mm Inner diameter: 450-550mm

Rollers of Steel tile double layer roof roll forming machine

Cutting blade

PLC Control Box

Entry Beach

corrugated iron sheet roofing tile making roll forming machine Received Goods Table

corrugated iron sheet roofing tile making roll forming machine profile drawing

Other relative roof roll forming machine

Our company other products

Relative raw material

Corrugated galvanized metal roofing sheet cold roll forming machine prices package and shipment photos

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce more than 6 kinds of panels.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

1. we can send our engineer to your site and do the training for your men. you just only bear the cost for our engineer's air ticket, visa, accommodations, food and transportation in your country.

2. You can send your men to our factory. we will teach them how to operate the machine without training charges.

3. Actually, there's another cheap and easy way to choose. Every machine leaves our factory with one book of operation manual. You can read through the manual first, and get familiar with the machine. Then we can get a video call, and teach you on-line on how to operate the machine.

4. Apart from the above training course, we also provide 2 years warranty for all the easily broken part of the machine for free and whole-life technical service support.